High-damp magnesium alloy vibration isolation structure and application thereof

A vibration damping structure, magnesium alloy technology, applied in vibration suppression adjustment, spring/shock absorber, non-rotation vibration suppression, etc., to achieve the effect of easy use, good vibration damping effect, and vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

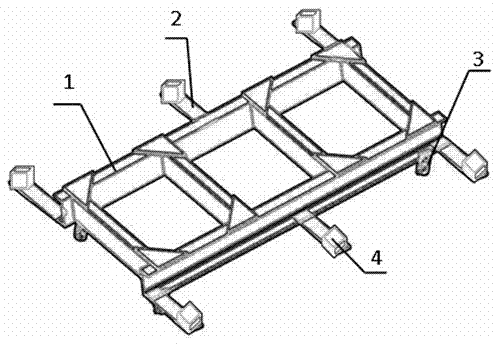

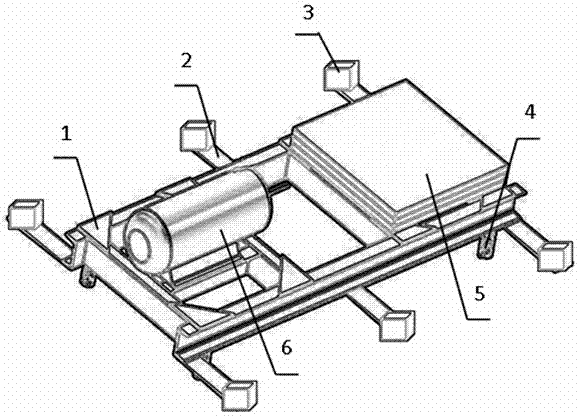

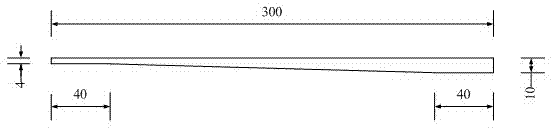

[0020] For specific implementation, see figure 1 with figure 2 , an application of a damping magnesium alloy vibration-damping structure, a high-damping magnesium alloy vibration-damping structure is designed on a platform 1 where a motor 6 and a weight block 5 are installed, including a high-damping magnesium alloy support 2 and a counterweight 3; the motor 6 and the weight block 5 are fixed on both sides of the platform 1, and the high-damping magnesium alloy support structure 2 is fixed on the platform 1 with screws at one end and the counterweight 3 (60×60×50mm 45 steel) is fixed with screws at the other end A spring is set on the bracket 4, and the high-damping magnesium alloy support 2 is 6 wedge-shaped variable-section shapes, which are installed symmetrically and evenly (the thicker part is connected to the platform); the vibrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com