Environmental protection and energy saving circulating fluidized bed boiler

A circulating fluidized bed, energy-saving technology, applied in the direction of fluidized bed combustion equipment, combustion type, fuel burned in a molten state, etc., can solve the problem of unreasonable secondary air structure, low separator separation efficiency, oxygen-poor areas, etc. problem, achieve the effect of saving energy consumption, reducing wear and tear, and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

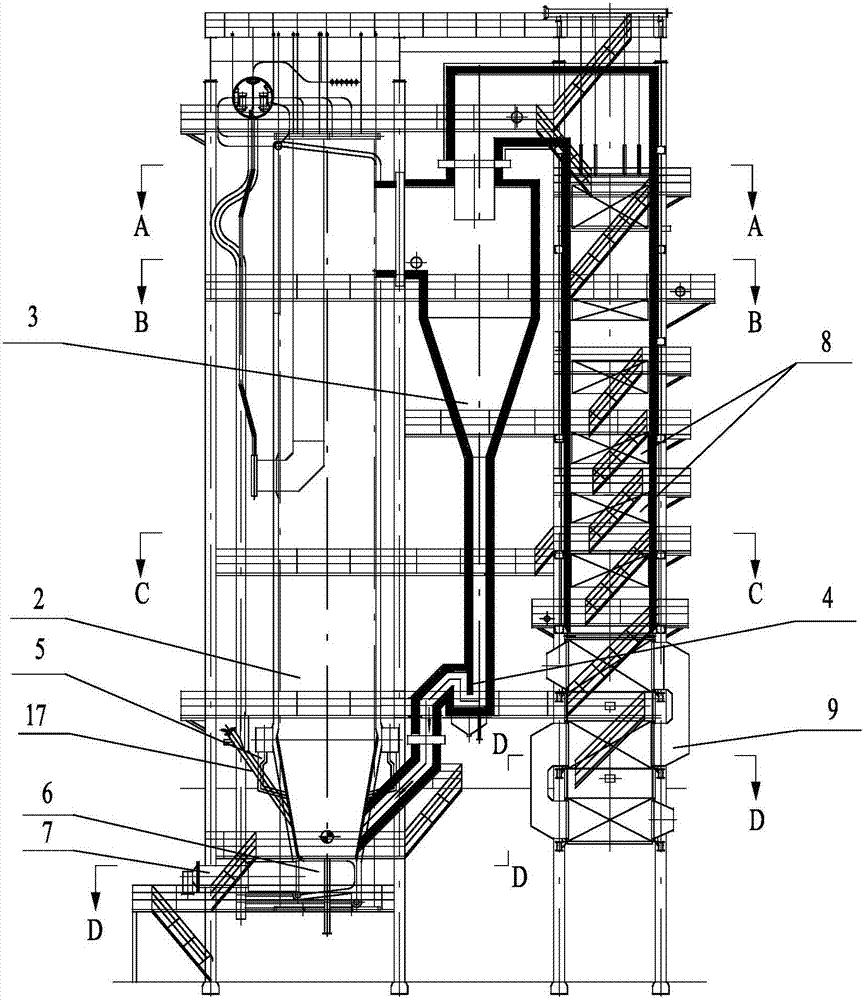

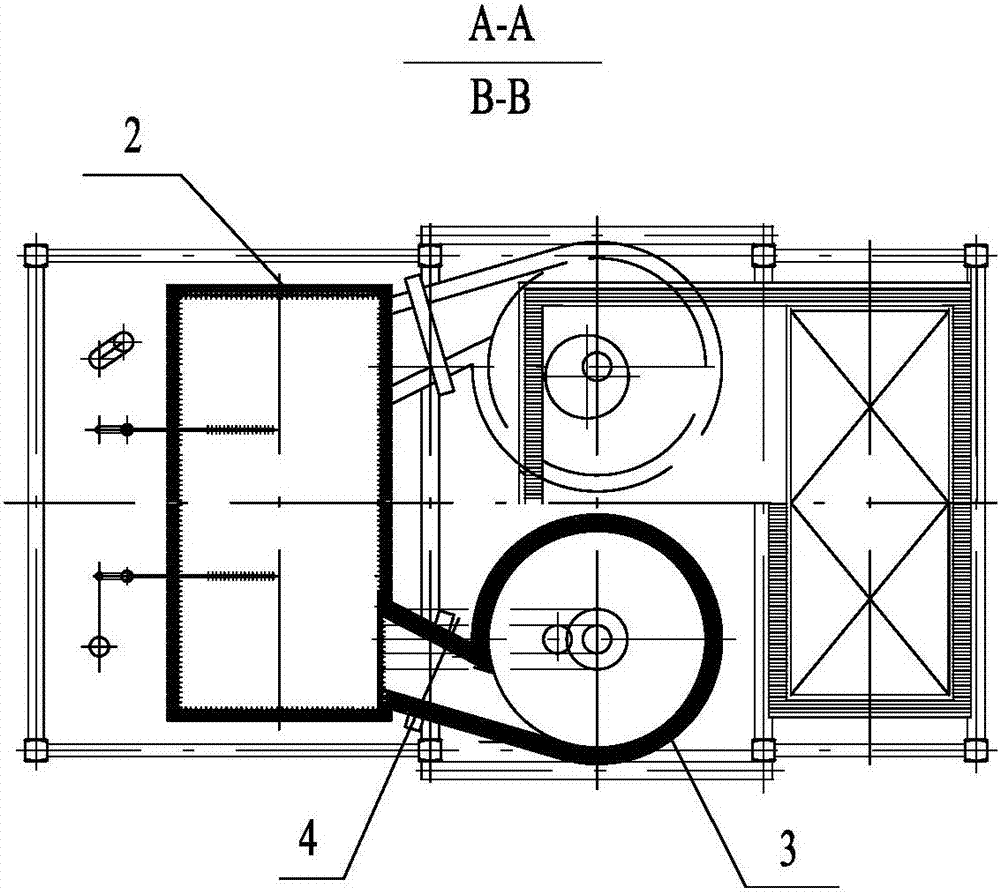

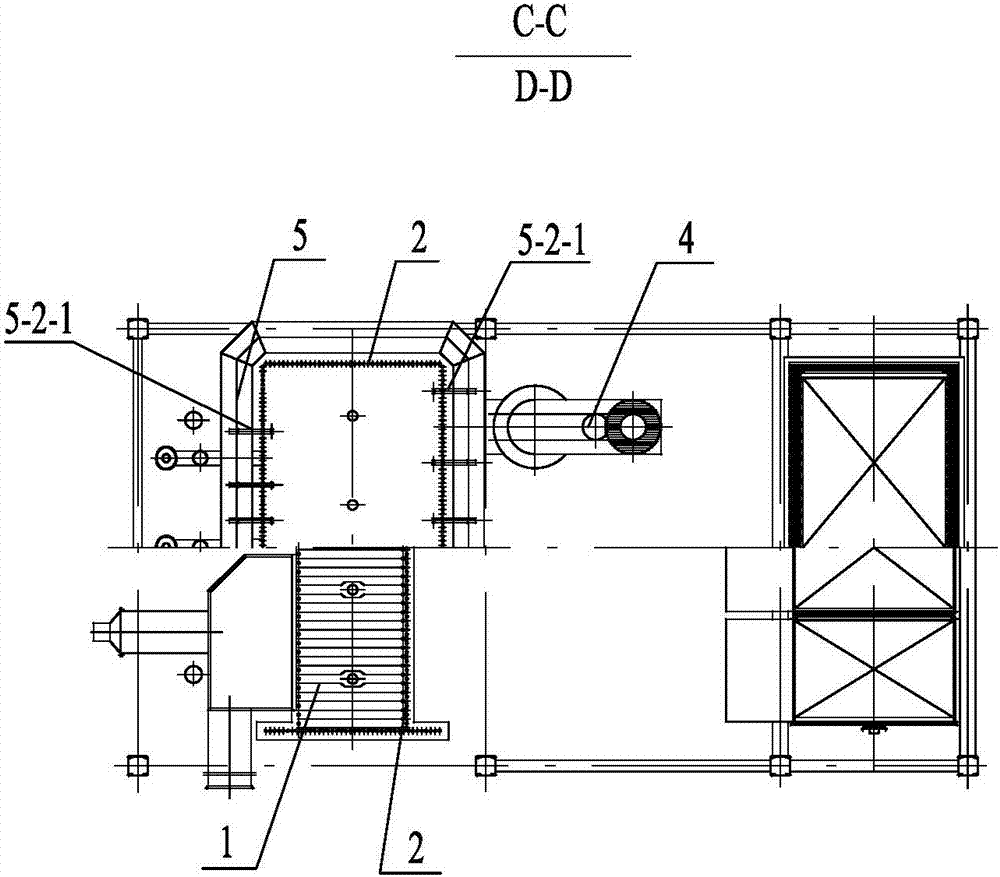

[0029] Specific implementation mode one: combine Figure 1 to Figure8 Describe this embodiment. An environmentally friendly and energy-saving circulating fluidized bed boiler in this embodiment includes a membrane water-cooled hearth 2, a cyclone separator 3, a feeder 4, a secondary air 5, an air chamber 6, and an ignition device 7 , the tail heating surface 8, the air preheater 9 and a plurality of air caps 1, the bottom of the membrane water-cooled hearth 2 is provided with a first air distribution plate, the first air distribution plate is evenly equipped with a plurality of air caps 1, the first air distribution plate The lower end of the air plate is provided with an air chamber 6, the side of the air chamber 6 is provided with an ignition device 7, the lower end side wall of the membrane water-cooled hearth 2 is provided with a coal delivery port 17, and the lower end of the membrane water-cooled hearth 2 is provided with two The secondary wind 5, the upper end outlet of...

specific Embodiment approach 2

[0034] Specific implementation mode two: combination Figure 4 and Figure 5 The present embodiment will be described. The inclination angle α of the first inclination section KL in the present embodiment is 15°. In such a setting, the falling particle flow of the attached wall directly scours the wear-resistant castable 10 during the descending process, thereby forming an effective protection for the furnace water wall. At the same time, the first inclined section KL can block the falling particle flow of the attached wall, so that it cannot Grinding the top surface of the castable 10 causes wear. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0035] Specific implementation mode three: combination Figure 4 and Figure 5 Describe this embodiment, the inclination angle β of the second inclination section LT of this embodiment 1 is 10°, the inclination angle β of the fourth inclination segment RP 2 is 15°. Such a design can make the membrane water-cooled hearth 2 form a good cone section, so that the falling particle flow of the wall can smoothly flow down the wall. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com