Self-heating layer, wooden floor with the self-heating layer and methods of making and using the same

A wood floor, self-heating technology, applied in the field of wood floors, can solve the problem of low heating efficiency of the self-heating layer, and achieve the effects of heat conversion efficiency, environmental protection, no noise, high heat conversion efficiency, and tight arrangement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

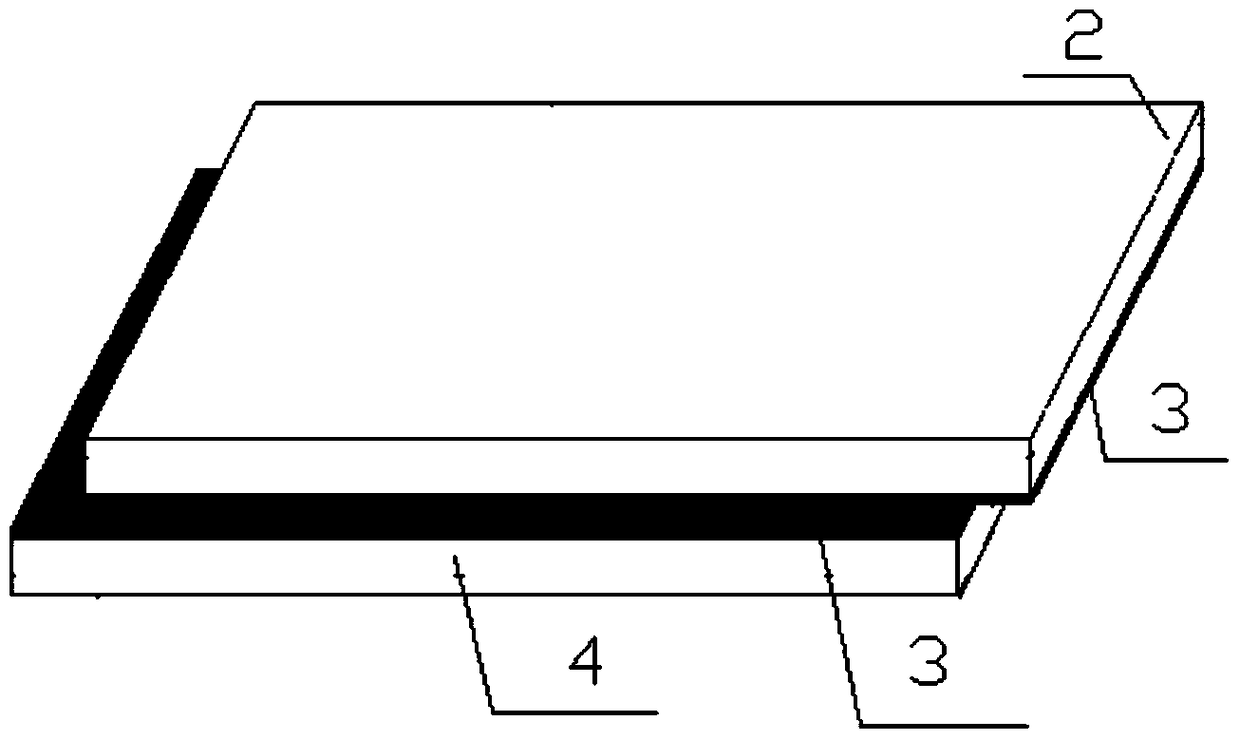

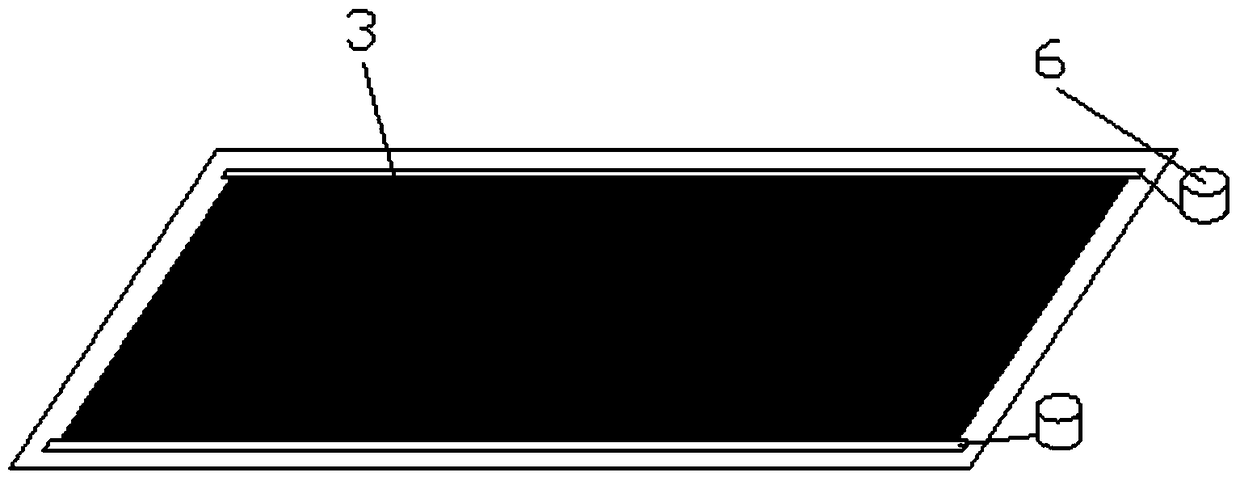

[0056] figure 1As shown, the present invention provides a self-heating wooden floor, comprising: an upper panel 2 and a lower panel 4; a heating layer 3 is also included; The coating is formed on the flat plate; the lower surface of the upper panel 2 and the upper surface of the lower panel 4 are coated with the heating layer 3; the upper panel 2, the heating layer 3 and the lower panel 4 are artificially The heat-pressing gluing process of the boards is closely combined to form a whole; the self-heating wooden floor is provided with edges according to a flush structure, and two adjacent self-heating wooden floors are connected by a flush-lapping method to connect the heating layers; the self-heating wooden floor The heating wooden floor also includes a bus 6, which is electrically connected to the heating layer at the outermost edge of the ground laid by the self-heating wooden floor. The structure and circuit connection schematic diagram of the bus 6 is shown in image 3 an...

Embodiment 2

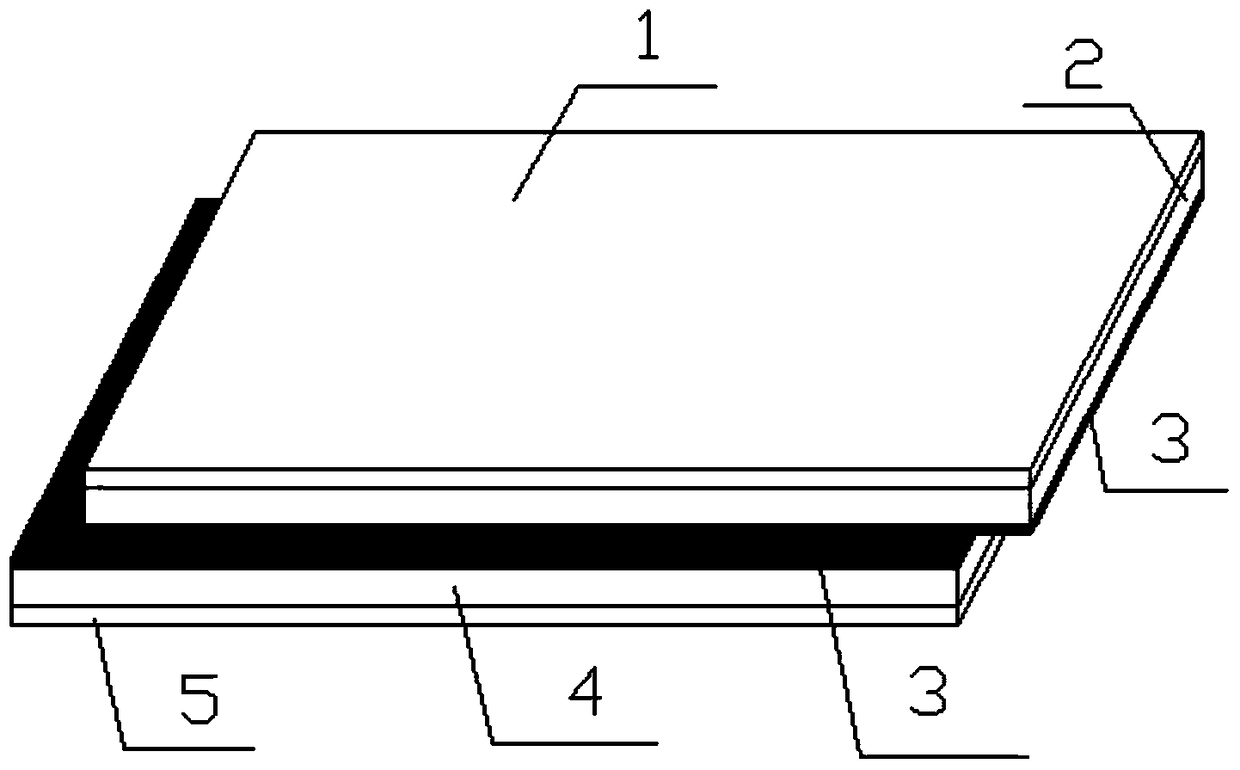

[0058] figure 2 As shown, the present invention provides a self-heating wooden floor, comprising: an upper panel 2 and a lower panel 4; a heating layer 3 is also included; The coating is formed on the flat plate; the lower surface of the upper panel 2 and the upper surface of the lower panel 4 are coated with the heating layer 3; the upper panel 2, the heating layer 3 and the lower panel 4 are artificially The heat-pressing gluing process of the boards is closely combined to form a whole; the self-heating wooden floor is provided with edges according to a flush structure, and two adjacent self-heating wooden floors are connected by a flush-lapping method to connect the heating layer; it also includes: The surface layer 1 and the bottom layer 5; the surface layer 1 and the bottom layer 5 are finishing layers; the surface layer 1 is located on the upper surface of the upper panel 2, and the bottom layer 5 is located on the lower surface of the lower panel 4; the surface layer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com