Ablation sensor based on metal sputtering thin film technology

A technology of metal sputtering and thin film technology, applied in the field of aerospace sensors, can solve the problems of insufficient resolution and precision, harsh test conditions, aircraft shell structure, difficulty in meeting the requirements of real-time measurement of aircraft surface ablation, etc., to improve resolution And measurement accuracy, the effect of continuous measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

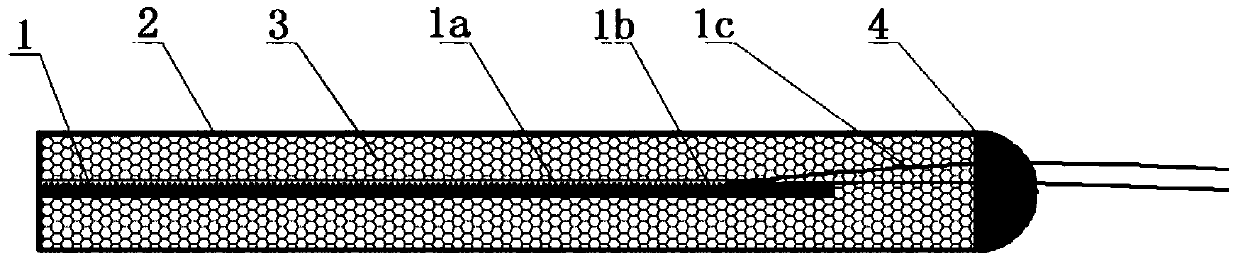

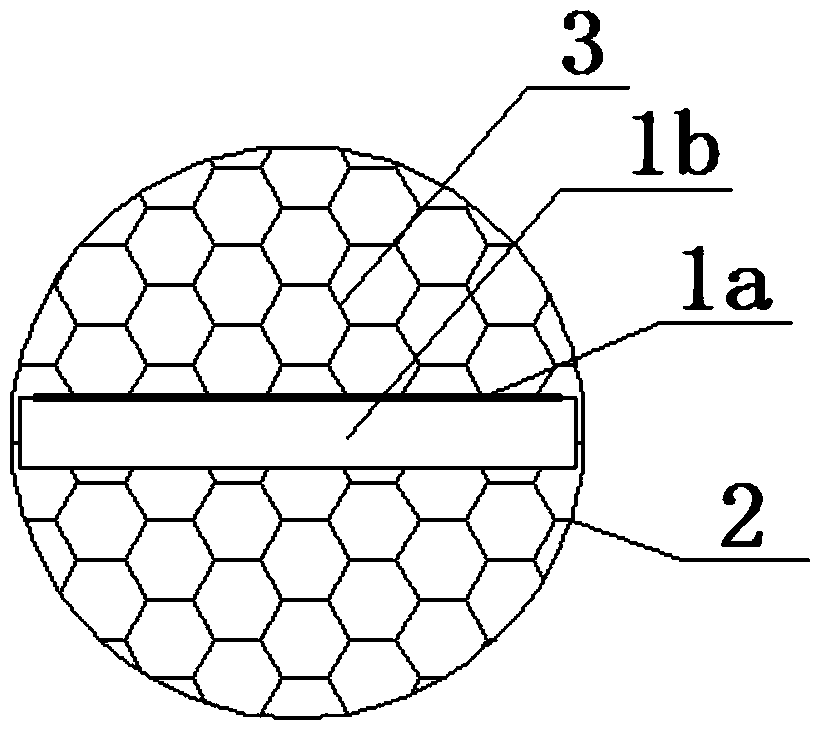

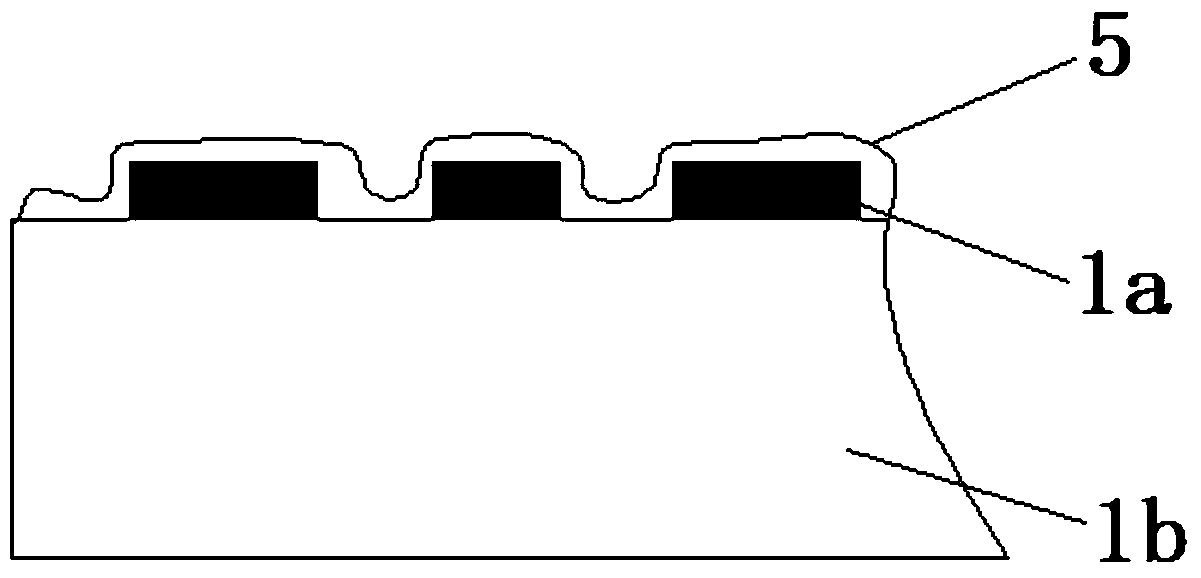

[0025] Referring to the accompanying drawings, the ablation sensor based on metal sputtering film according to the present invention includes a housing 2 , an ablation sensor sensitive component 1 , and a filler 3 . The shell 2 is a hollow shell made of metal material with one end closed, and the melting point of the shell material is close to the ablation temperature of the ablation material to be measured. The length of the casing 2 is longer than that of the sensitive component 1 of the ablation sensor, so as to ensure that the lead wire of the lead wire 1c is firm. The sensitive component of the ablation sensor consists of a wire grid 1a, a base material 1b and a lead 1c. When making the wire grid 1a, the metal is first plated on the base material 1b by the metal sputtering thin film process to form a metal film, and then the metal film plated on the base material 1b is etched through an etching process to form a metal wire grid 1a, the resistance of the wire grid 1a is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com