Semiconductor testing circuit and method for detecting conductive properties of tested piece

A technology for testing circuits and detection methods, which is applied in the field of semiconductors, and can solve problems such as the increase in resistance value, Joule heat, and the inability to test the resistance value of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

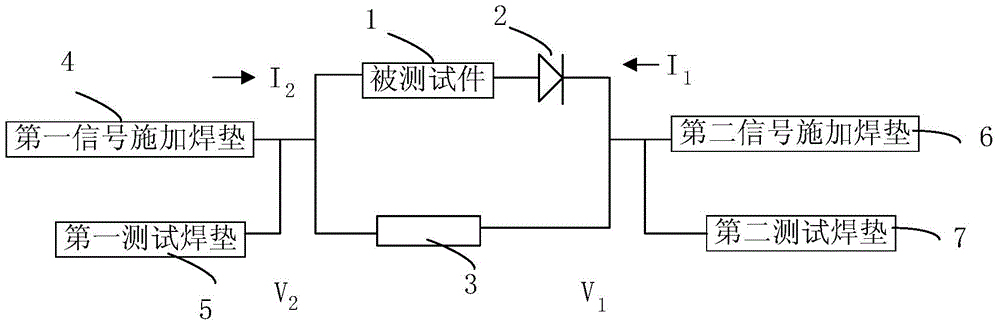

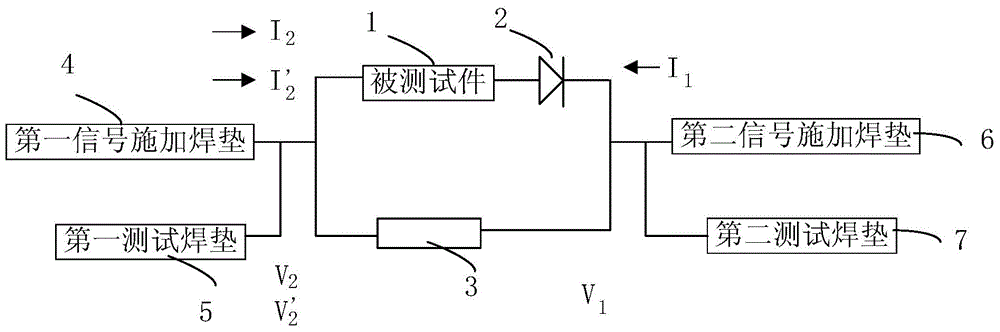

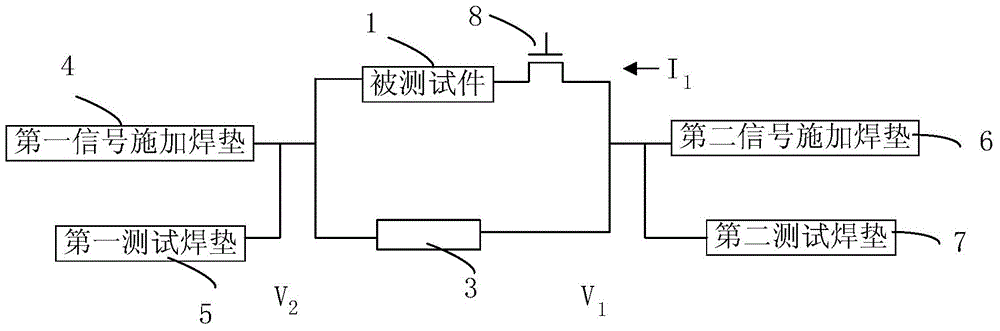

[0030] As mentioned in the background technology, for a test piece with a large resistance value, on the one hand, the test machine in the prior art has a certain allowable range due to power, current, and voltage. If it exceeds the above allowable range, the resistance value of the resistor cannot be tested. On the other hand, due to the large resistance and high heat generation, it affects the resistance value of the tested piece itself, making the test results inaccurate. In order to solve the above-mentioned technical problems, the present invention provides the following test circuit: the device under test is connected in series with the switch; a resistor is connected in parallel with the series circuit of the device under test and the switch; The pad is connected to one end of the parallel circuit; the second signal application pad and the second test pad are connected to the other end of the parallel circuit; the first signal application pad, the first test pad, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com