Formaldehyde gas-sensing material, corresponding formaldehyde gas-sensing element and preparation method of element

A production method and formaldehyde gas technology, applied in the direction of material resistance, etc., can solve the problems of high working temperature, difficulty in large-scale production, and complicated production process of gas sensor components, and achieve the effects of low cost, fast induction, and good flexibility resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

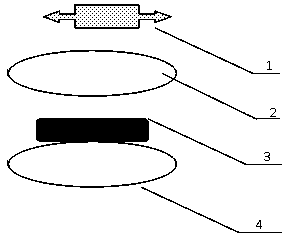

Image

Examples

Embodiment 1

[0038] (1) According to the ratio in the table, weigh each component to form a powder mixture:

[0039] Inorganic components SnO 2 In 2 o 3 WO 3 Pt PD CaO Content (wt%) 75 16 4 1 2 2 Particle size (nm) ≤80 ≤70 Median diameter (nm) ≤50 ≤50

[0040] Put the above 100 parts by mass of powder into 310 parts by mass of absolute ethanol solution, and stir with a stirrer at a speed of 200 r / min for 4 hours to obtain a uniformly mixed emulsion.

[0041] (2) Put the uniformly mixed emulsion into a low-temperature vacuum drying oven, and perform vacuum drying at 30°C to remove absolute ethanol.

[0042] (3) Weigh the inorganic powder and organic slurry carrier for gas-sensitive layer slurry according to the following ratio:

[0043] Based on 100 parts of dried inorganic powder, add 3.5 parts of hydrogenated castor oil, 43 parts of terpineol, 8.5 parts of polyvinyl butyral, and 6 parts of dibutyl phthalate, ...

Embodiment 2

[0047] (1) According to the ratio in the table, weigh each component to form a powder mixture:

[0048] Inorganic components SnO 2 In 2 o 3 WO 3 Pt PD CaO Content (wt%) 78 14 3 1.5 1.5 2 Particle size (nm) ≤80 ≤70 Median diameter (nm) ≤50 ≤50

[0049] Put 100 parts by mass of the mixture powder above into 310 parts by mass of anhydrous ethanol solution, and stir for 4 hours at a speed of 200 r / min with an electric stirrer to obtain a uniformly mixed emulsion.

[0050] Subsequent process steps are the same as in Example 1, and the formaldehyde gas sensor S2 is produced.

Embodiment 3

[0052] The preceding process steps are the same as in Example 1. In step (5), the laser sintering temperature is 520° C., and the sintering time is 0.16 h. After sintering, the required formaldehyde gas sensor S3 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com