Preparation method of energy conversion fiber

An energy conversion and fiber technology, applied in the field of textile fibers, can solve problems such as energy conservation and environmental protection, lower heat energy collection efficiency, narrow application range, etc., and achieve wide processing temperature range, sensitivity to environmental temperature changes, and good fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

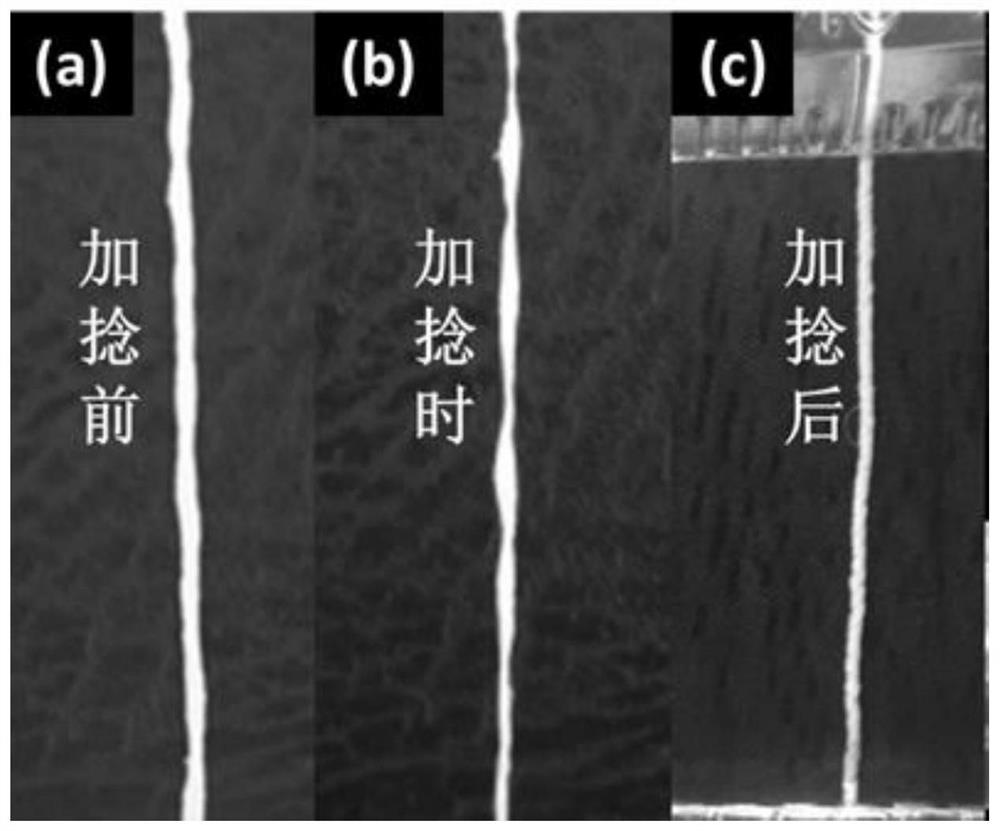

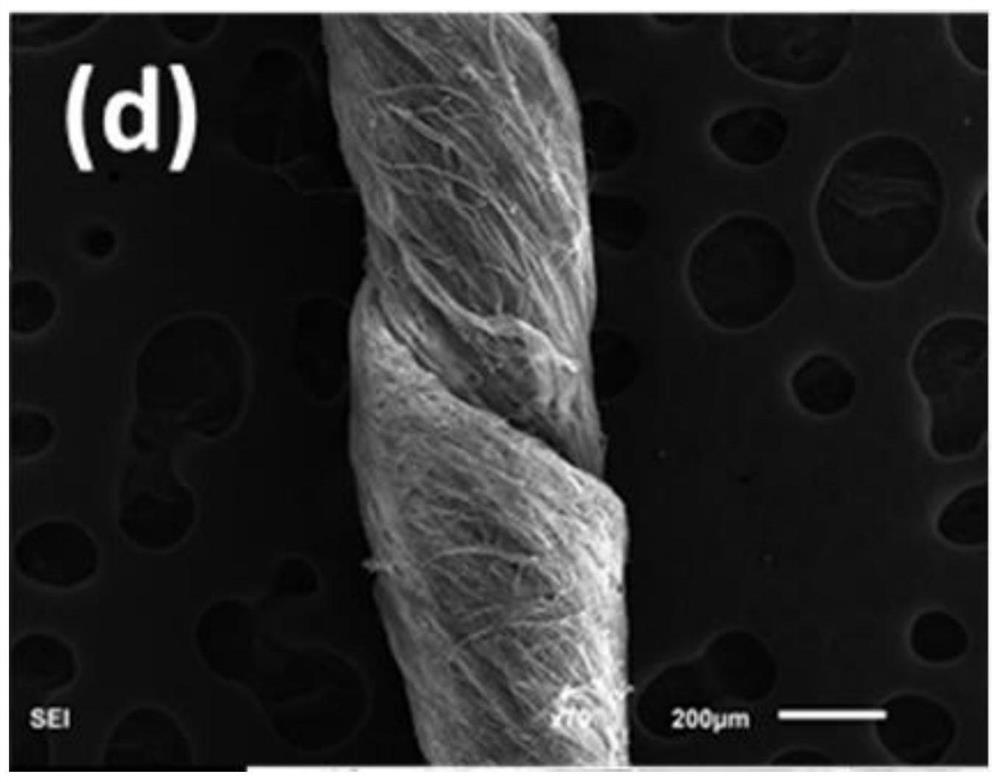

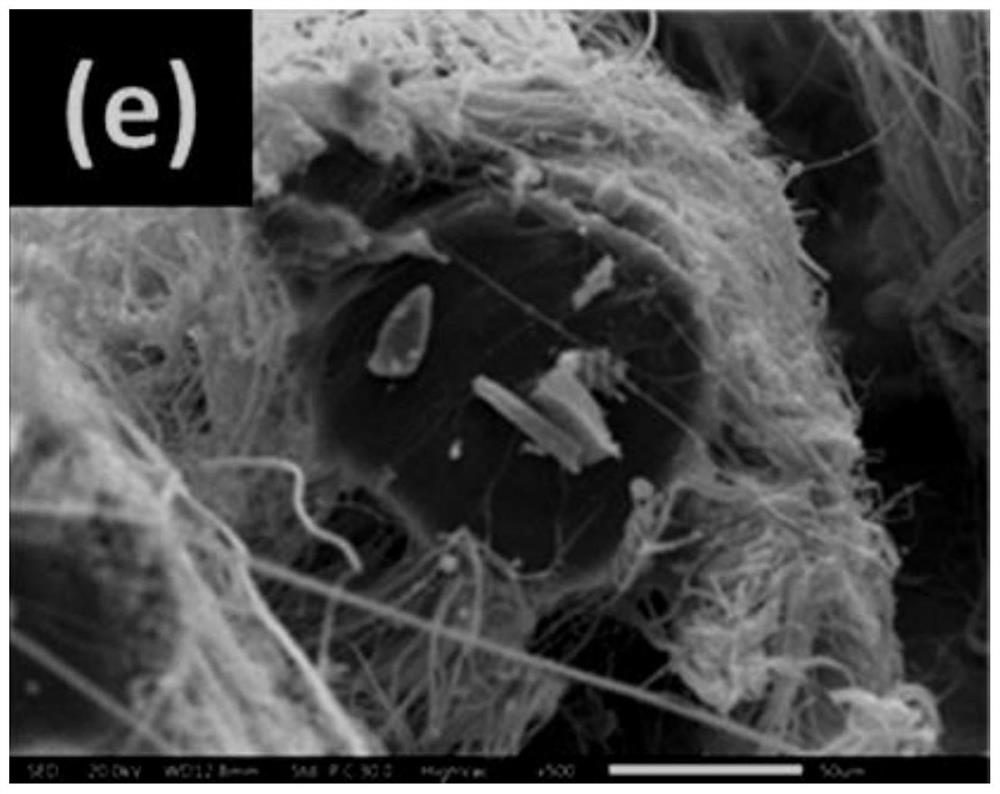

Image

Examples

Embodiment 1

[0044] A preparation method for energy conversion fibers, which comprises the steps of:

[0045] 1) Preparation of thermoplastic polymer / cellulose acetate butyrate masterbatch: take PA6 masterbatch (preferred PA6 masterbatch grade is 1013NW8) and cellulose acetate butyrate (CAB, preferably CAB grade) with a mass ratio of 20:80 381-0.5, its viscosity is small) mixed evenly, and then through twin-screw melt extrusion and pelletizer granulation to obtain the masterbatch of PA6 and CAB blending;

[0046] 2) Preparation of nanofibers with piezoelectric effect: Take the masterbatch of PA6 and CAB blended prepared in step 1), PA11 masterbatch with piezoelectric effect and barium titanate and place them in a drum oven for drying. The temperature of the fixed-drum oven is 100°C, and the drying is continued for 15 hours to remove the moisture in the masterbatch;

[0047] Take the dry PA6 and CAB blended masterbatch and put it in the twin-screw of the two-component composite spinning ma...

Embodiment 2

[0054] A preparation method for energy conversion fibers, which comprises the steps of:

[0055] 1) Preparation of thermoplastic polymer / cellulose acetate butyrate masterbatch: take PP masterbatch with a mass ratio of 30:70 (preferred PP masterbatch grade is HJ200) and cellulose acetate butyrate (CAB, preferably CAB grade 381-0.5, its viscosity is small) mixed evenly, and then through twin-screw melt extrusion and pelletizer granulation to obtain PP and CAB blended masterbatch;

[0056] 2) Preparation of nanofibers with piezoelectric effect: Take the masterbatch of PP and CAB blended prepared in step 1), PA11 masterbatch with piezoelectric effect and barium titanate and place them in a drum oven for drying. The temperature of the fixed-drum oven is 110°C, and the drying is continued for 17 hours to remove the moisture in the masterbatch;

[0057] Take the dry PP and CAB blended masterbatch and put it in the twin-screw of the two-component composite spinning machine as the ski...

Embodiment 3

[0062] A preparation method for energy conversion fibers, which comprises the steps of:

[0063] 1) Preparation of thermoplastic polymer / cellulose acetate butyrate masterbatch: take PET masterbatch (preferred PET masterbatch grade is LW-xg309) and cellulose acetate butyrate (CAB, preferably CAB) with a mass ratio of 25:75 The brand name is 381-0.5, its viscosity is small) and mixed evenly, and then the masterbatch of PET and CAB blending is obtained through twin-screw melt extrusion and pelletizer granulation;

[0064] 2) Preparation of nanofibers with piezoelectric effect: Take the masterbatch of PET and CAB blended and the PVDF masterbatch with piezoelectric effect prepared in step 1) and place them in a drum oven for drying, set the drum oven The temperature is 120°C, and it is dried continuously for 15 hours to remove the moisture in the masterbatch;

[0065] Take the dry masterbatch blended with PET and CAB and place it in the twin-screw of the two-component composite sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com