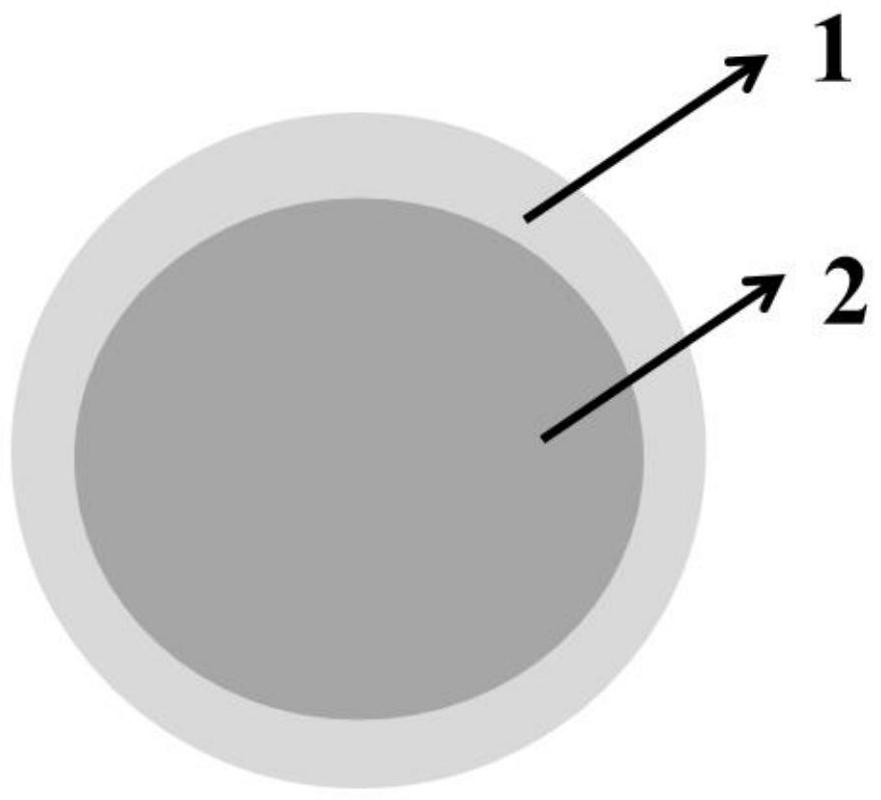

High-thermal-conductivity phase change microcapsule as well as preparation method and application thereof

A technology of phase change microcapsules and high thermal conductivity, which is applied in the direction of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc. It can solve the problems of poor sensitivity to environmental temperature changes, increased risk of core material leakage, and easy aging. Achieving the effects of sensitivity to environmental temperature changes, dense shell material, and low risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

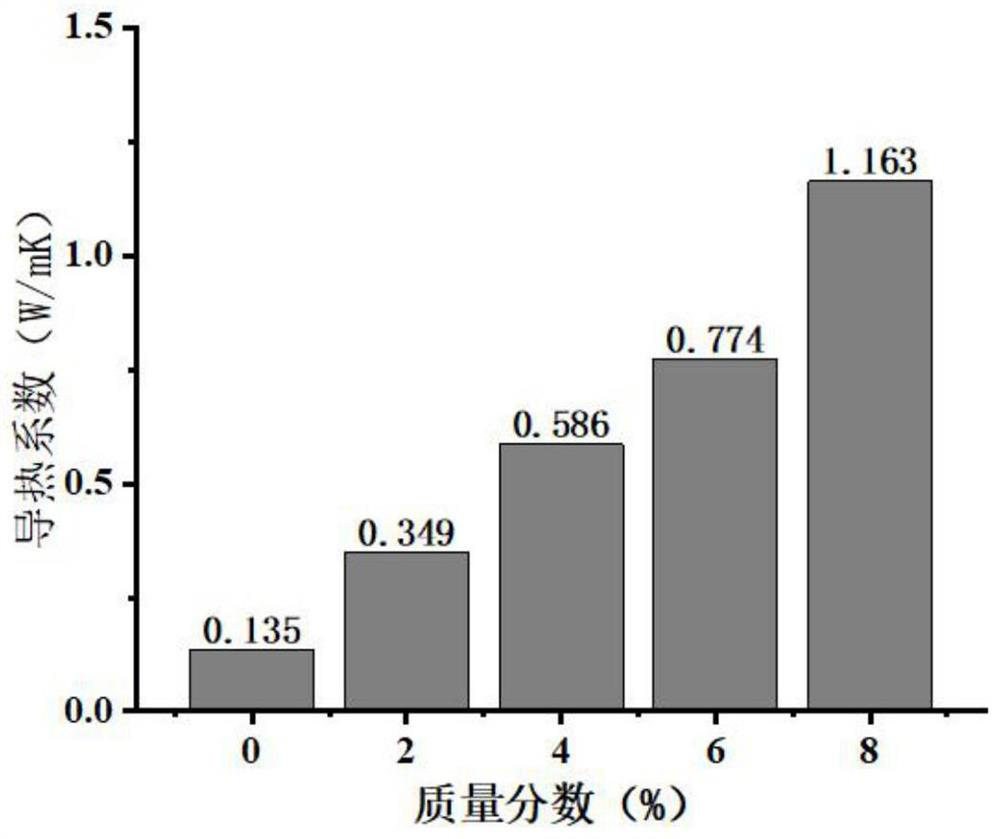

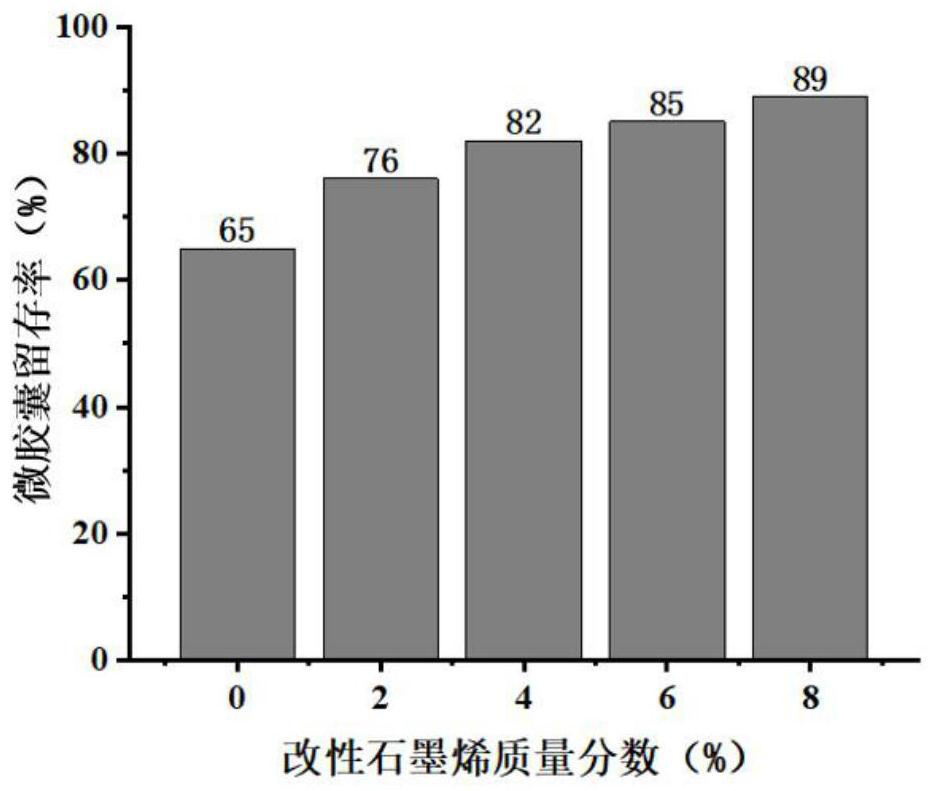

Embodiment 1

[0056] (1) Dissolve 0.44g of palmitic acid and 0.8g of aluminum chloride hexahydrate in 200mL of ethanol aqueous solution (the ethanol concentration is 200g / L), then add 5g of graphene, and stir while heating in a water bath (75°C; 300r / min) to obtain a lipophilic modified graphene suspension, filter the lipophilic modified graphene suspension, and dry the filter residue to obtain lipophilic modified graphene powder.

[0057] (2) Mix n-tetradecane and n-hexadecane at a weight ratio of 1:1 until the mixture is completely miscible, and stand without delamination to obtain a core material liquid.

[0058] Dissolve 0.4 g of benzoyl peroxide powder in 20 g of methyl methacrylate (in liquid state), stir to dissolve it completely, and prepare a shell material solution.

[0059] Dissolve 1 g of polyvinyl alcohol powder in 100 mL of deionized water (water bath temperature is 90°C) to obtain a surfactant solution, and pour the surfactant solution into a three-necked flask, which is plac...

Embodiment 2

[0064] (1) Dissolve 0.44g of palmitic acid and 0.8g of aluminum chloride hexahydrate in 200mL of ethanol aqueous solution (the ethanol concentration is 200g / L), then add 5g of graphene, and stir while heating in a water bath (75°C; 300r / min), The lipophilic modified graphene suspension is obtained, the lipophilic modified graphene suspension is filtered, and the filter residue is dried to obtain lipophilic modified graphene powder.

[0065] (2) Mix n-tetradecane and n-hexadecane at a weight ratio of 1:3 until the mixture is completely miscible, and stand without delamination to obtain a core material liquid.

[0066] Weigh 0.2 g of benzoyl peroxide powder and dissolve it in 20 g of methyl methacrylate (in liquid state), stir to make it completely dissolve, and prepare a shell material solution.

[0067] Weigh 1g of polyvinyl alcohol powder and dissolve it in 100mL of deionized water (water bath temperature 90°C) to obtain a surfactant solution, and pour the surfactant solution...

Embodiment 3

[0072] (1) Dissolve 0.44g of palmitic acid and 0.8g of aluminum chloride hexahydrate in 200mL of ethanol aqueous solution (the ethanol concentration is 200g / L), then add 5g of graphene, and stir while heating in a water bath (75°C; 300r / min) to obtain a lipophilic modified graphene suspension, filter the lipophilic modified graphene suspension, and dry the filter residue to obtain lipophilic modified graphene powder.

[0073] (2) Mix n-tetradecane and n-hexadecane at a weight ratio of 1:1 until the mixture is completely miscible, and stand without delamination to obtain a core material liquid.

[0074] Dissolve 0.4 g of benzoyl peroxide powder in 20 g of methyl methacrylate (in liquid state), stir to dissolve it completely, and prepare a shell material solution.

[0075] Dissolve 1 g of polyvinyl alcohol powder in 100 mL of deionized water (water bath temperature is 90°C) to obtain a surfactant solution, and pour the surfactant solution into a three-necked flask, which is plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com