Amorphous tin dioxide modified multilayer cobalt oxide material, preparation method thereof and formaldehyde gas-sensitive detection application

A technology of tin dioxide and cobalt oxide, which is applied in the direction of tin oxide, cobalt oxide/cobalt hydroxide, analytical materials, etc., can solve the problems of inability to realize trace detection and high detection temperature requirements, and meet the requirements of high sensitivity and preparation process Simple, highly responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

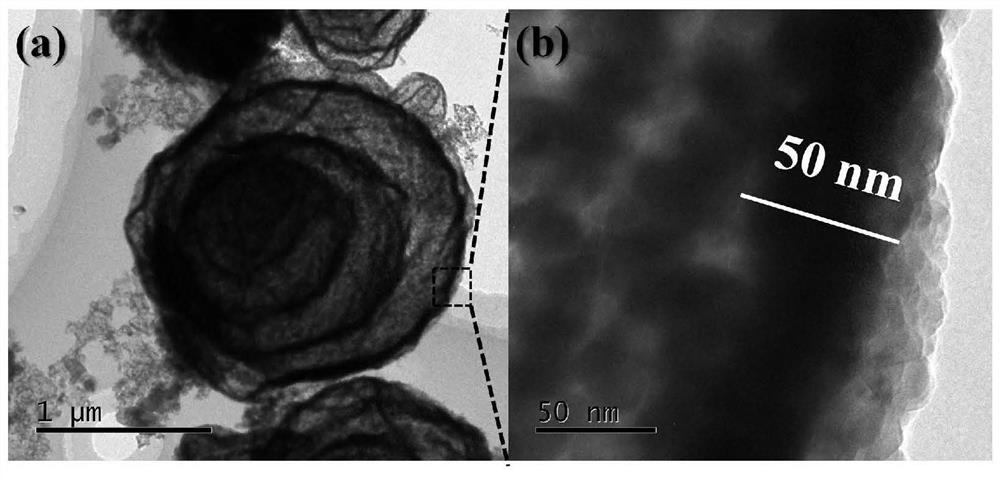

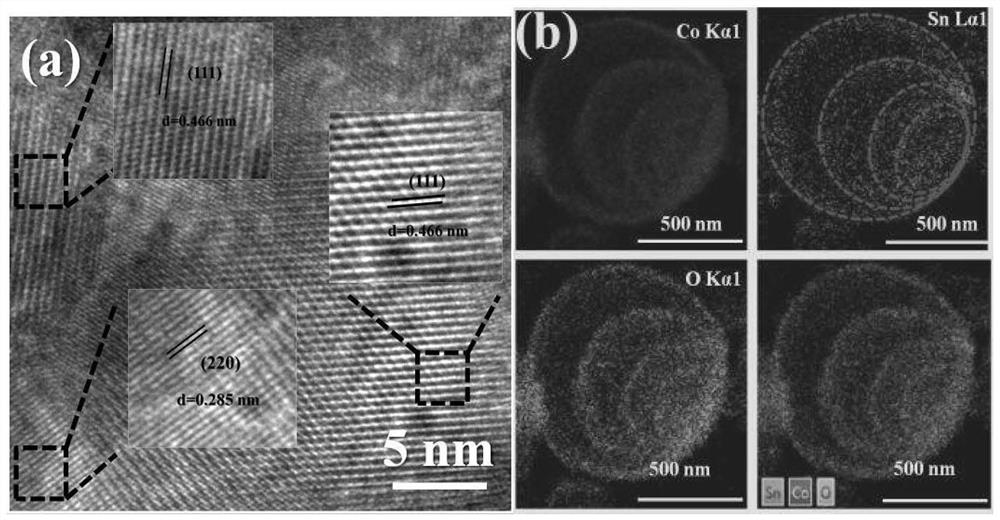

[0038] A kind of amorphous tin dioxide modified multilayer cobalt oxide material and preparation method thereof

[0039] (1) Preparation of multilayer cobalt oxide materials

[0040] There are many methods for preparing cobalt-based coordination polymer precursors in the prior art, and the present invention uses a hydrothermal reaction method to prepare the precursors. Add 30mg of cobalt nitrate hexahydrate and 20mg of isophthalic acid into the mixed solution of 5mL of acetone and 5mL of dimethylamide, stir and mix thoroughly, pour into the reaction kettle, react at 160°C for 4 hours, and then centrifuge , and obtain a precursor after drying. Weigh 60 mg of the precursor and put it into a muffle furnace, raise the temperature up to 500°C at a rate of 5°C / min at room temperature, then calcinate at 500°C in an air atmosphere for 10 minutes, and naturally cool down to room temperature to obtain a multilayer shell cobalt oxide material.

[0041] (2) Preparation of amorphous tin...

Embodiment 2

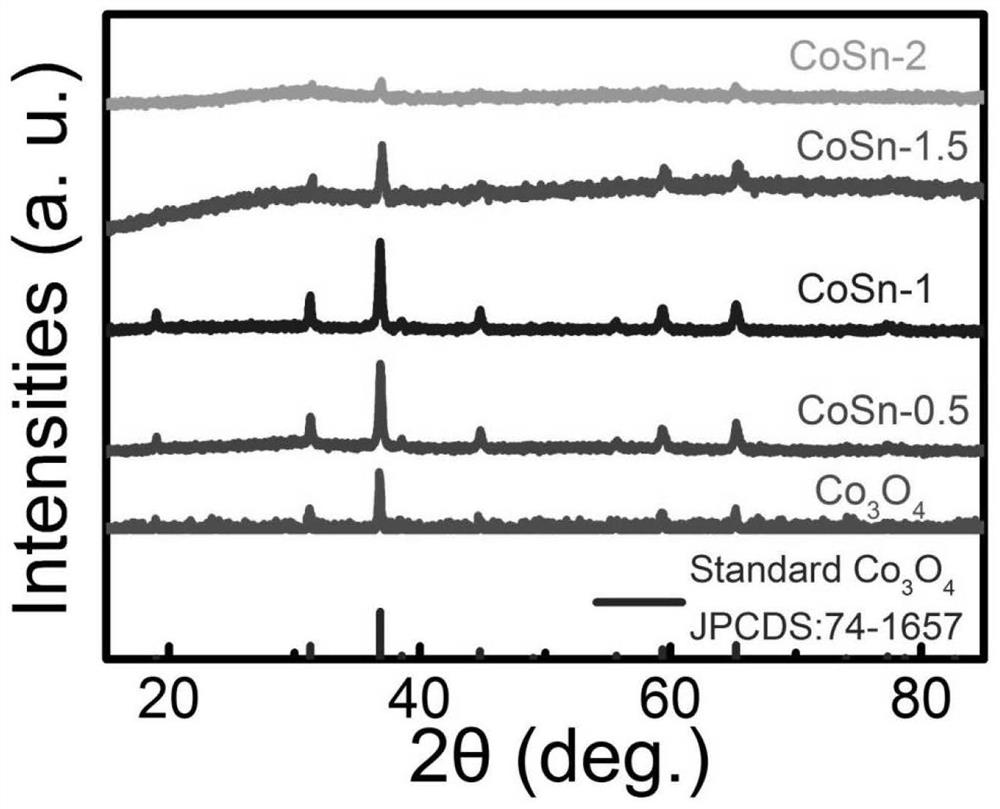

[0047] Oxygen vacancies regulation method of different amorphous tin dioxide modified multilayer cobalt oxide materials

[0048] The difference between this example and Example 1 is that in step (2.3), the oil bath reaction time was adjusted from 1h to 0.5h, 1.5h and 2h, and the rest were the same as in Example 1, and the obtained materials were named CoSn- 0.5, CoSn-1.5, CoSn-2. By controlling the electrodisplacement reaction time, the reaction intensity of tin ions replacing cobalt ions can be controlled, and then the controllable adjustment of the surface oxygen vacancy defect concentration can be realized. like Figure 4 As shown, with the change of reaction time, the oxygen vacancy defect O ov The proportion in the O1s spectrum also changed.

Embodiment 3

[0050] Formaldehyde detection application of amorphous tin dioxide modified multi-layer cobalt oxide material

[0051] (1) The amorphous tin dioxide modified multilayer cobalt oxide material prepared in Example 1-2: CoSn-0.5, CoSn-1, CoSn-1.5 and CoSn-2 were mixed with absolute ethanol to form a slurry, and placed side by side Disperse in an ultrasonic disperser for 10 minutes to reduce particle agglomeration.

[0052] (2) Coat the uniform thin paste gas-sensing slurry on the Al with electrodes at both ends 2 o 3 The ceramic tube was left to dry naturally to obtain a uniformly coated gas sensor. The obtained gas sensor was placed on a gas aging bench and aged at 200° C. for 5 days.

[0053] (3) Place the gas sensor prepared in the above steps on the test gas sensor test platform, and perform gas sensor performance tests on CoSn-0.5, CoSn-1, CoSn-1.5, and CoSn-2 sensors at a test temperature of 100-300°C. The relationship curves of the responsivity of each sensor to gases s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com