Nano air-sensitive thin film and preparation method thereof

A thin-film and gas-sensing technology, which is applied in the direction of material resistance, can solve the problems of limited application, high price of long-period fiber gratings, and sensors that have not been widely used and verified, achieving wide application fields, good gas-sensing characteristics, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

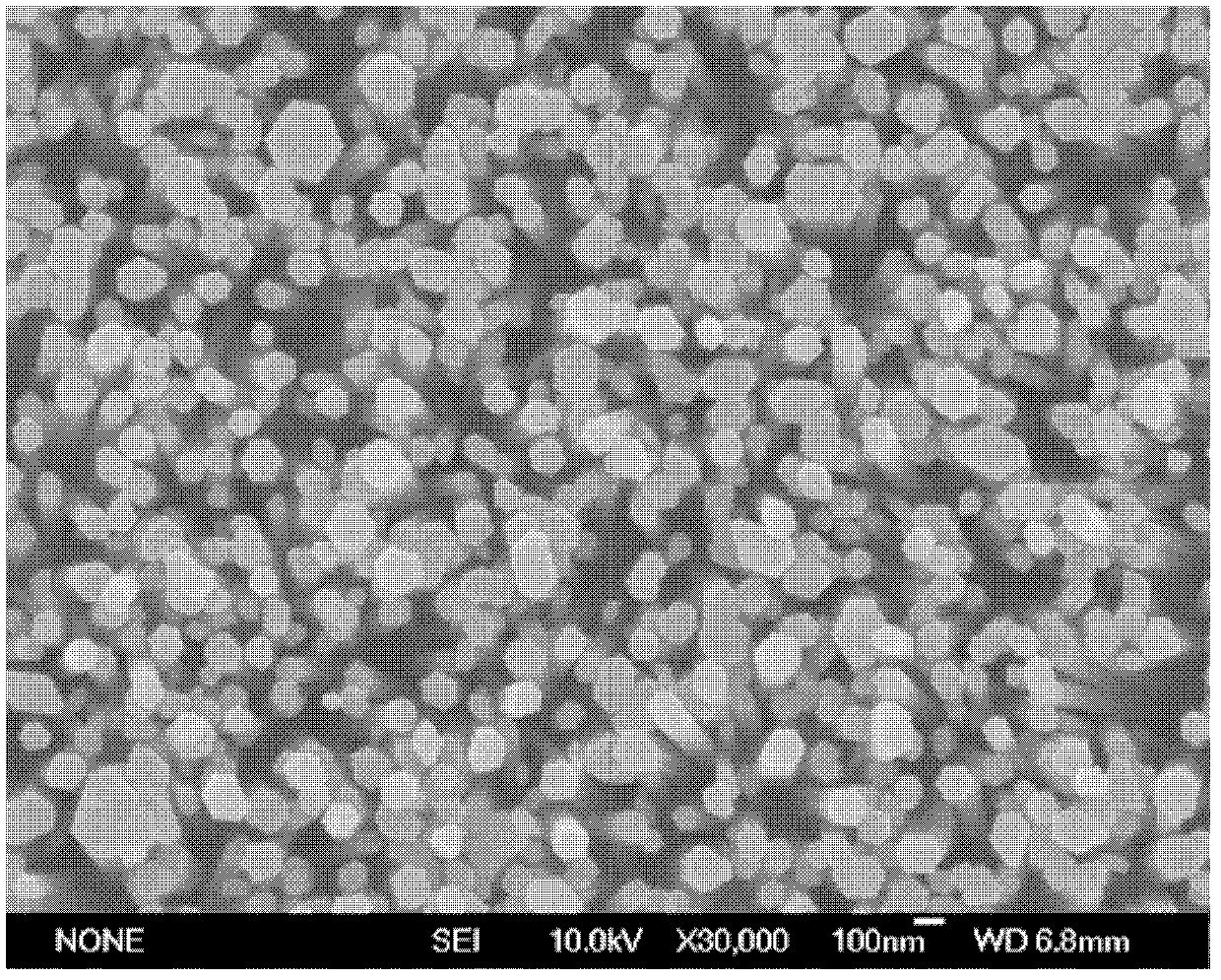

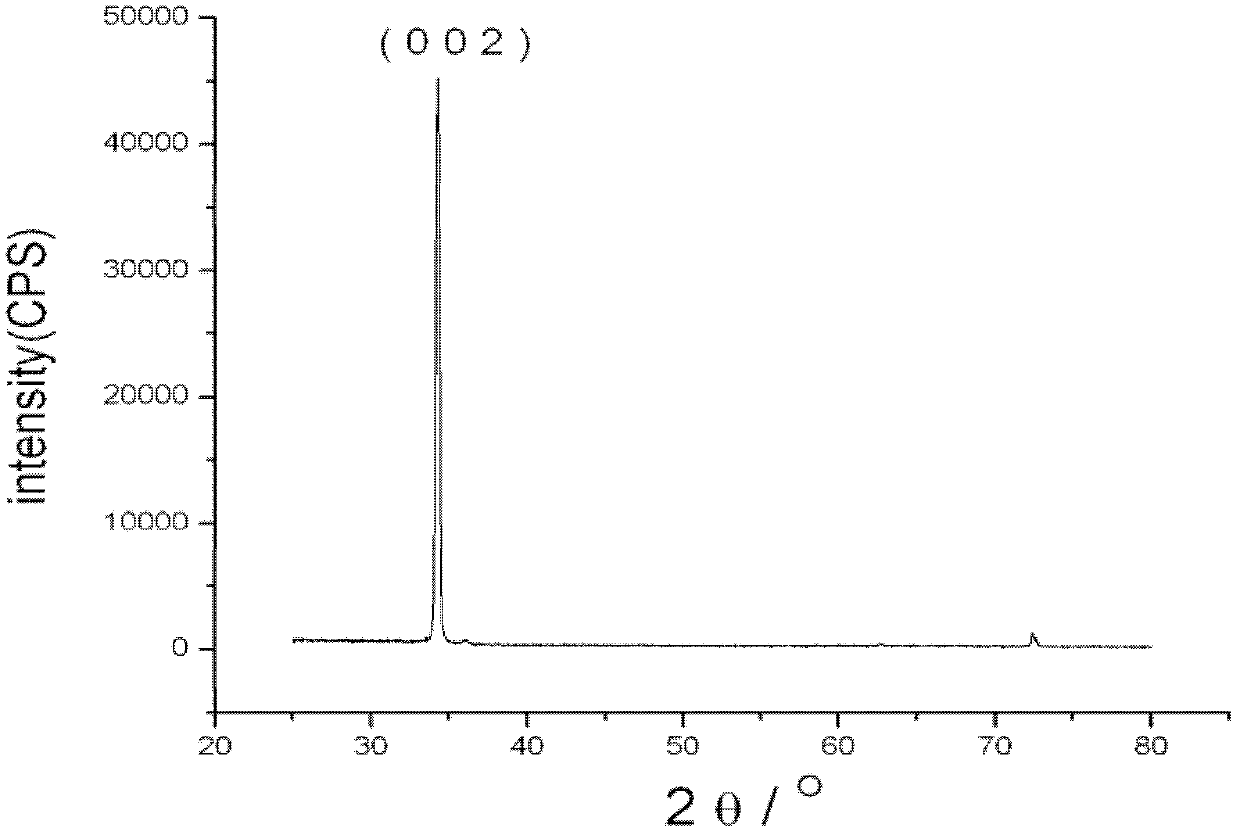

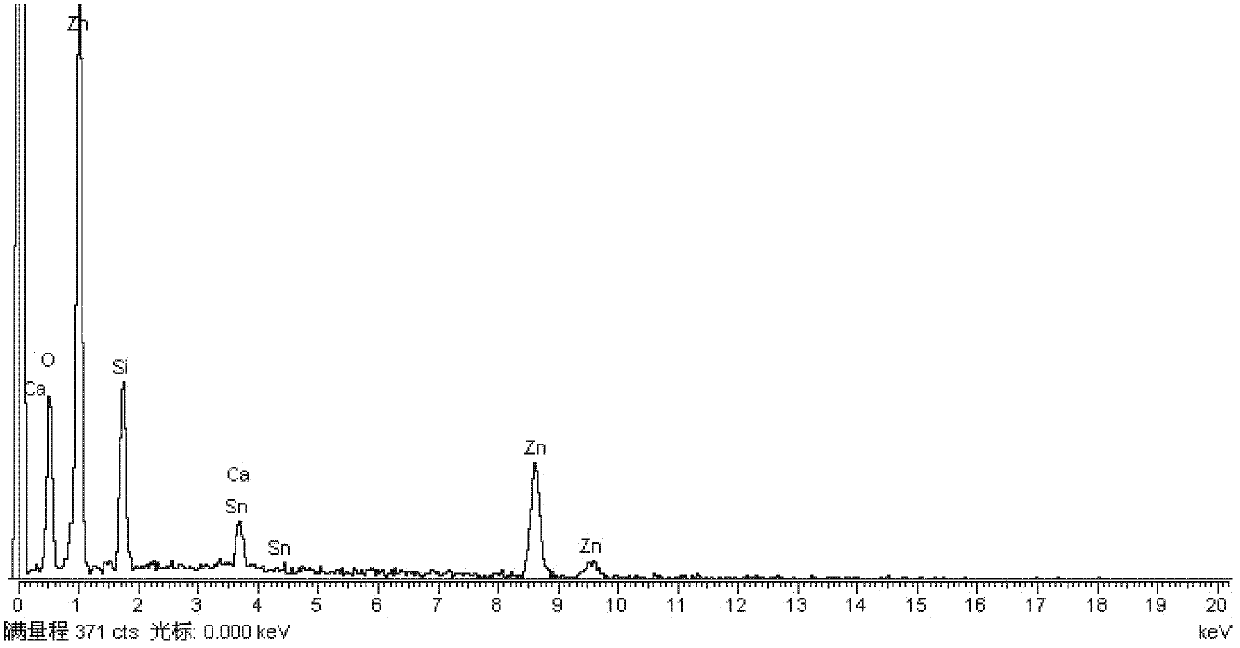

[0047] The preparation process of the Sn-doped ZnO nanometer gas-sensitive film of the present invention is as follows:

[0048] 1. Seed preparation:

[0049] The preparation of seeds requires the preparation of a matrix solution and a tin salt solution, respectively, and after mixing the two solutions, a seed layer is prepared.

[0050] (1) Zn(AC) 2 (Zinc acetate) 5.742g with C 3 H 7 NO (ethanolamine) 7.0848ml was added to 10mL (CH 3 ) 2 In CHOH (isopropanol), the matrix solution is obtained;

[0051] (2) SnCl 4 ·5H 2 O (tin tetrachloride) 0.4207g dissolved in 10mL CH 3 CH 2 In OH (absolute ethanol), get tin salt solution;

[0052] (3) mixing the matrix solution and the tin salt solution, and using a magnetic stirrer to fully stir to obtain a seed solution;

[0053] (4) place the cleaned glass substrate in the seed solution in a glue homogenizer, spin-coat at a speed of 7000 rev / min, and form a film;

[0054] (5) Then, gradient heat treatment is adopted, and the t...

Embodiment 2

[0066] The preparation process of the Sn-doped ZnO nanometer gas-sensitive film of the present invention is as follows:

[0067] 1. Seed preparation:

[0068] The preparation of seeds requires the preparation of a matrix solution and a tin salt solution, respectively, and after mixing the two solutions, a seed layer is prepared.

[0069] (1) Zn(AC) 2 (Zinc acetate) 1.914g with C 3 H 7 NO (ethanolamine) 7.0848ml was added to 10mL (CH 3 ) 2 In CHOH (isopropanol), the matrix solution is obtained;

[0070] (2) SnCl 4 ·5H 2 O (tin tetrachloride) 0.5609g dissolved in 10mL CH 3 CH 2 In OH (absolute ethanol), get tin salt solution;

[0071] (3) mixing the matrix solution and the tin salt solution, and using a magnetic stirrer to fully stir to obtain a seed solution;

[0072] (4) place the cleaned glass substrate in the seed solution in a glue homogenizer, spin-coat at a speed of 7000 rev / min, and form a film;

[0073] (5) then treated at 350°C for 15 minutes; then treated ...

Embodiment 3

[0081] The preparation process of the Sn-doped ZnO nanometer gas-sensitive film of the present invention is as follows:

[0082] 1. Seed preparation:

[0083] The preparation of seeds requires the preparation of a matrix solution and a tin salt solution, respectively, and after mixing the two solutions, a seed layer is prepared.

[0084] (1) Zn(AC) 2 (Zinc acetate) 1.914g with C 3 H 7 NO (ethanolamine) 7.0848ml was added to 10mL (CH 3 ) 2 In CHOH (isopropanol), the matrix solution is obtained;

[0085] (2) SnCl 4 ·5H 2 O (tin tetrachloride) 0.4207g dissolved in 10mL CH 3 CH 2 In OH (absolute ethanol), get tin salt solution;

[0086] (3) mixing the matrix solution and the tin salt solution, and using a magnetic stirrer to fully stir to obtain a seed solution;

[0087] (4) place the cleaned glass substrate in the seed solution in a glue homogenizer, spin-coat at a speed of 7000 rev / min, and form a film;

[0088] (5) then treated at 350°C for 10 minutes; then treated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com