Low-melting-point glass sizing agent and preparation method thereof

A low-melting glass and paste technology, applied in the field of low-melting glass paste and its preparation, to achieve the effects of improving insulation resistance, reducing dielectric loss, and stabilizing physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

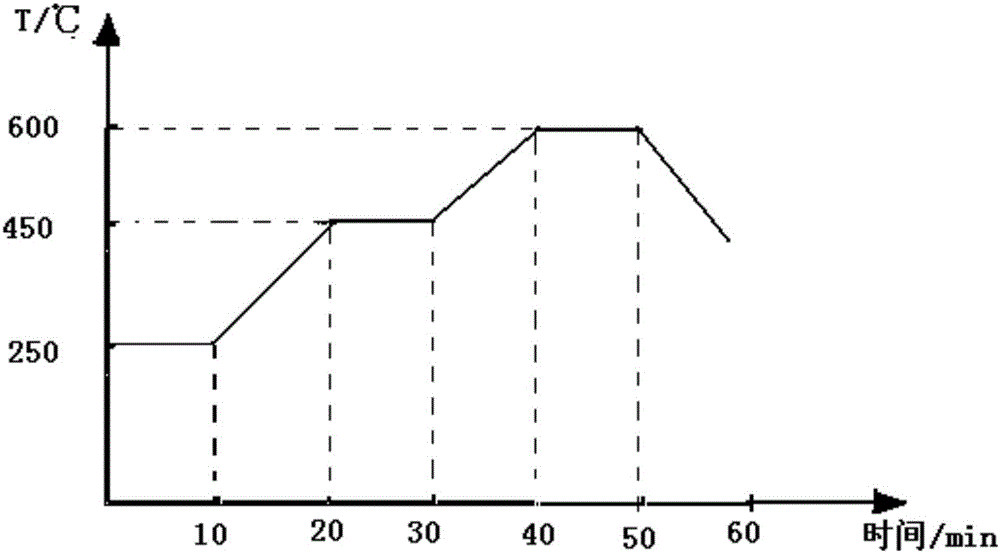

Method used

Image

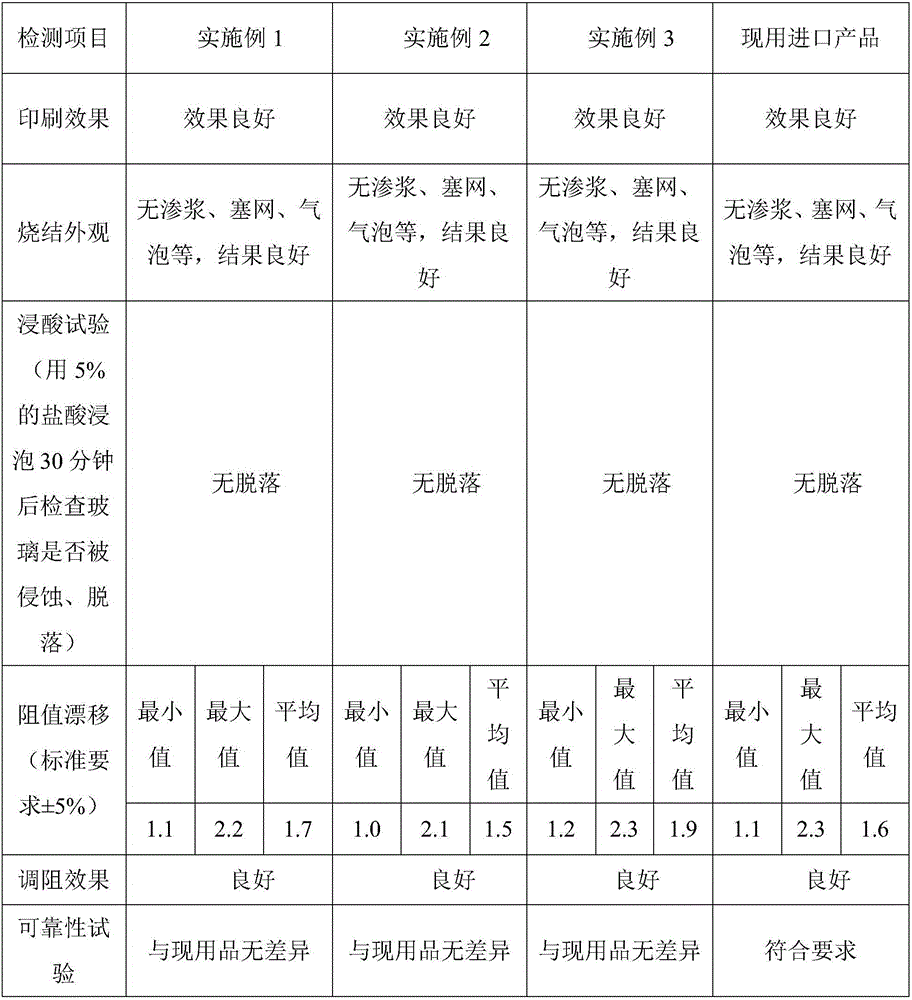

Examples

Embodiment 1

[0034] The low-melting point glass paste of the present embodiment is made up of following weight percent raw material:

[0035] Glass powder 65%, inorganic pigment 4%, organic vehicle 31%, of which glass powder is B 2 o 3 -SiO 2 -Bi 2 o 3 System glass powder, converted into oxides, is composed of the following components by weight percentage: B 2 o 3 10.5%, SiO 2 14%, Bi 2 o 3 66%, Nb 2 o 5 2.5%, ZnO 1.5%, CaO 1%, Al 2 o 3 2.5%, TiO 2 2%; Inorganic pigments are inorganic composite oxides, composed of the following transition metal oxides by weight percentage: NiO 40%, CoO 20%, Ti 2 O 40%; the organic vehicle is made up of the following raw materials in weight percentage: high molecular polymer 15% (wherein ethyl cellulose 11%, polyvinyl alcohol resin 4%), organic solvent 80% (wherein diethylene glycol butyl ether 20% , terpineol 20%, diethylene glycol butyl ether acetate 20%, ethyl oleate 10%, dimethyl phthalate 10%), organic additive 5% (choosing silicone...

Embodiment 2

[0046] The low-melting point glass paste of the present embodiment is made up of following weight percent raw material:

[0047] Glass powder 60%, inorganic pigment 3%, organic vehicle 37%, among which glass powder is B 2 o 3 -SiO 2 -Bi 2 o 3 System glass powder, converted into oxides, is composed of the following components by weight percentage: B 2 o 3 12%, SiO 2 19.5%, Bi 2 o 3 58%, Nb 2 o 5 1.5%, ZnO 3%, BaO 1%, Al 2 o 3 3%, ZrO 2%; Inorganic pigments are inorganic composite oxides, composed of the following transition metal oxides by weight percentage: NiO 40%, CoO 20%, Ti 2 O 40%; the organic vehicle is made up of the following raw materials in weight percent: high molecular polymer 20% (select ethyl cellulose for use), organic solvent 75% (wherein diethylene glycol butyl ether 20%, terpineol 20%, diethylene glycol 15% of glycol butyl ether acetate, 10% of ethyl oleate, 10% of dimethyl phthalate), 5% of organic additives (select polyacrylate).

[0048]...

Embodiment 3

[0057] The low-melting point glass paste of the present embodiment is made up of following weight percent raw material:

[0058] 70% glass powder, 3% inorganic pigment, 27% organic vehicle, of which glass powder is B 2 o 3 -SiO 2 -Bi 2 o 3 System glass powder, converted into oxides, is composed of the following components by weight percentage: B 2 o 3 16%, SiO 2 21%, Bi 2 o 3 51%, Nb 2 o 5 2.5%, ZnO 1.5%, BaO 1%, Al 2 o 3 4.5%, ZrO 1.5%, TiO 2 1%; Inorganic pigments are inorganic composite oxides, composed of the following transition metal oxides by weight percentage: NiO 40%, CoO 20%, Ti 2 O 40%; organic vehicle is made up of following raw material of percentage by weight: polymer 10% (select ethyl cellulose for use), organic solvent 85% (wherein diethylene glycol butyl ether 30%, terpineol 20%, diethylene glycol 15% glycol butyl ether acetate, 10% castor oil, 10% dimethyl phthalate), and 5% organic additives (select polyacrylate).

[0059] Its preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com