Bias-voltage adsorption cooling device

A cooling device and access device technology, which is applied in the manufacture of capacitors, electrical components, capacitors, etc., can solve the problem that the cooling effect is not obvious and satisfactory, the cooling effect is limited, and the heat exchange effect between the main drum and the base film surface is not ideal, etc. problem, to achieve significant cooling effect, few changes, and enhance the effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

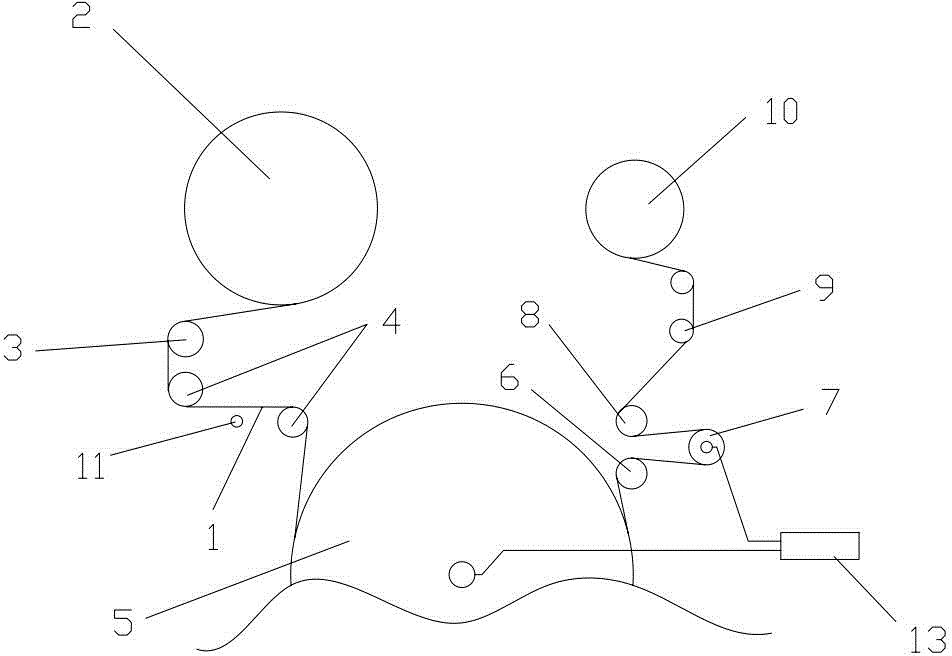

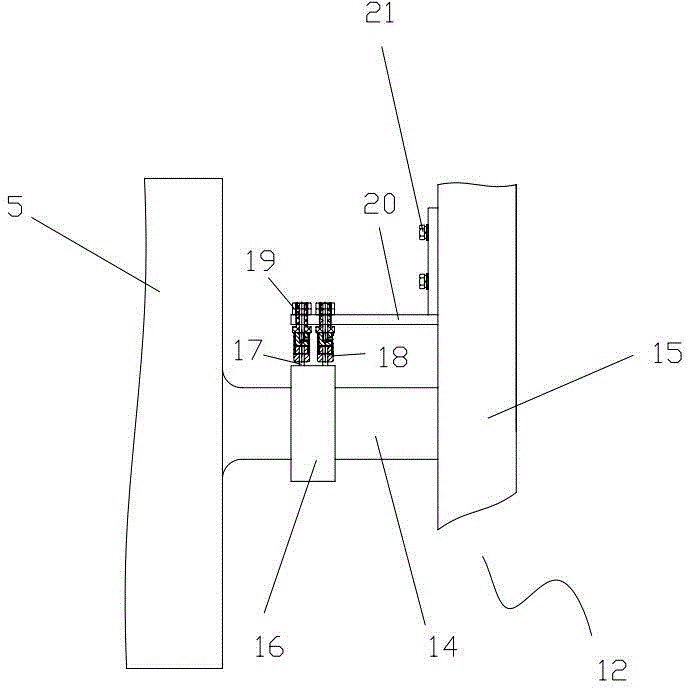

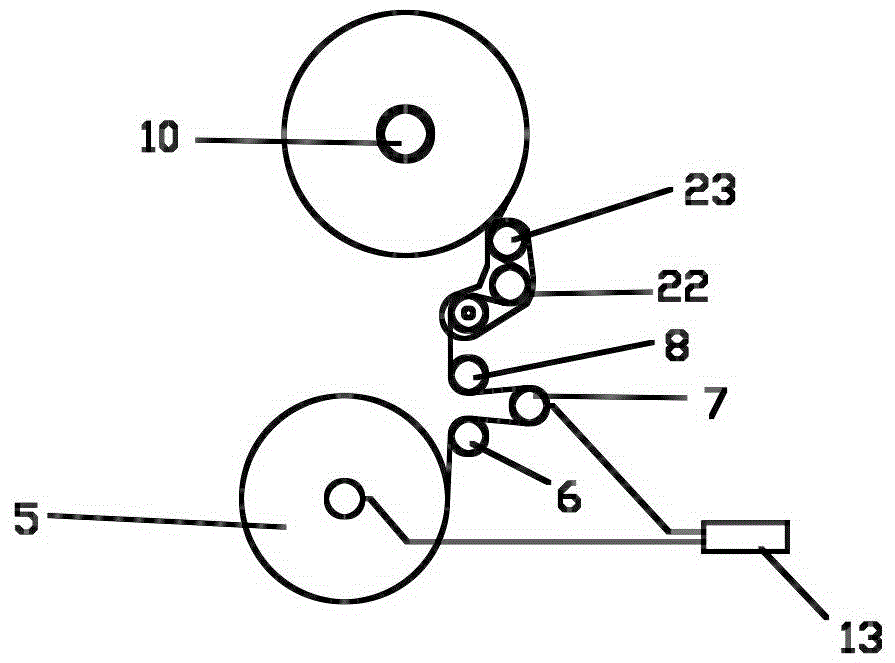

[0013] A bias adsorption cooling device described in Example 1, such as figure 1 As shown, it includes an unwinding shaft 2 wound with a film 1 and the film passes through the rubber roller 3, the guide roller 4, the main drum 5, the first measuring roller 6, the tension roller 7, the second measuring roller 8, the swing arm system 9 and the Rewinding shaft 10; also includes an oil shielding system 11 for spraying the film; the main drum and the tension roller are provided with a carbon brush access device 12, and the carbon brush access device is connected to a 220V DC bias power supply 13 . Since the base film above the metal vapor has to withstand high temperature baking of 1200°C, in order to avoid thermal damage to the base film by the metal vapor, it is necessary to use the mechanical refrigeration method of the main drum to cool the base film, while on the main drum and the tension roller Connecting to a 220V DC bias power supply can enhance the heat exchange efficienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com