Infrared sensor and packaging structure thereof and preparation method thereof

A technology of infrared sensor and packaging structure, which is applied in semiconductor devices, electric radiation detectors, final product manufacturing, etc., can solve the problems of high cost, high cost, low production capacity, etc., reduce process cost and difficulty, and increase effective fill factor , the effect of reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

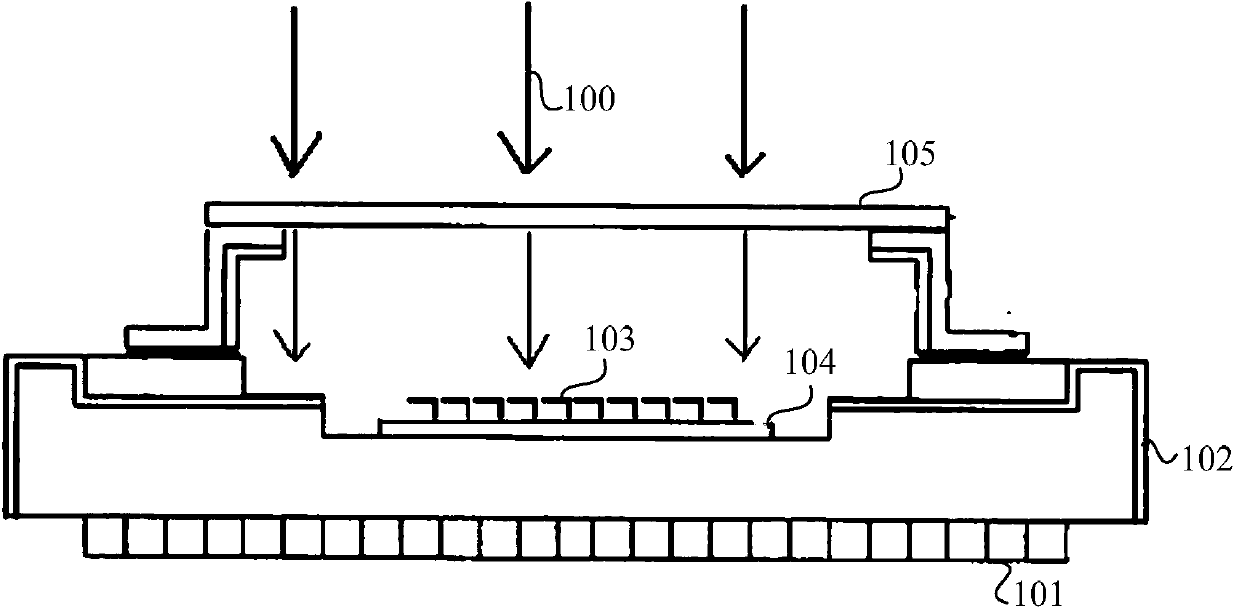

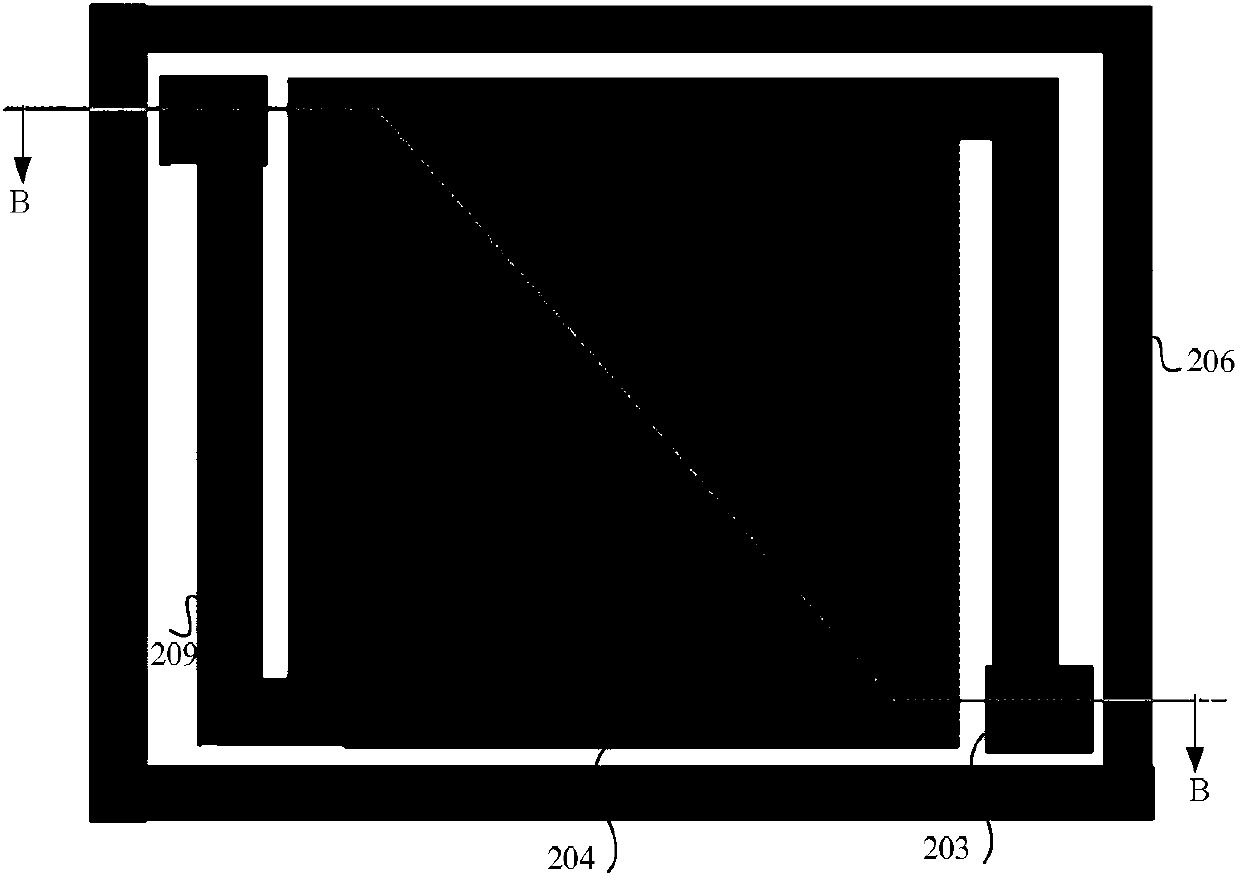

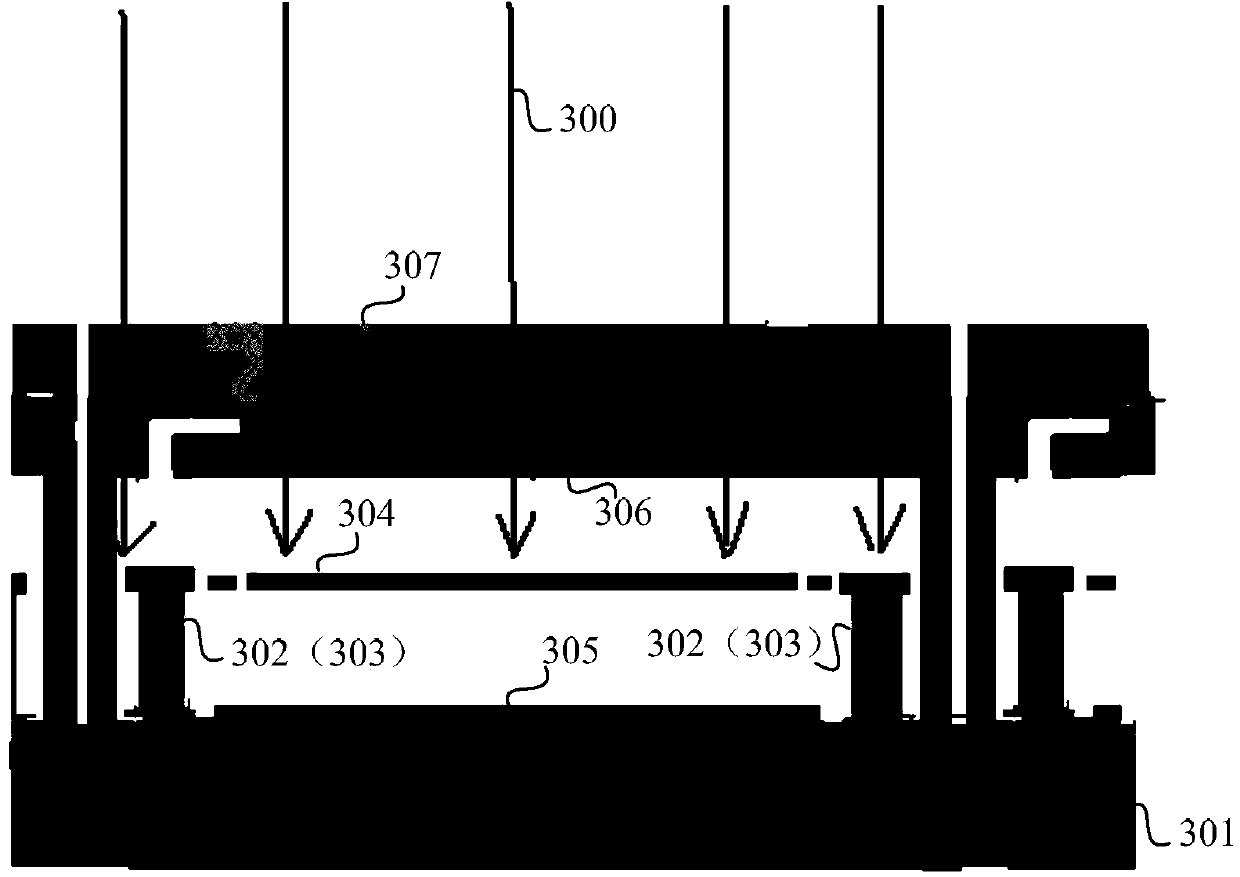

[0028] The present invention provides an infrared sensor and its packaging structure, wherein the infrared sensor and its packaging structure include:

[0029] The readout circuit substrate is used to collect and process the output signal of the infrared sensor;

[0030] The infrared sensor unit, including some pixels in the infrared sensor array, is used to convert the infrared radiation incident on the infrared sensor unit into an electrical signal and output it from the readout circuit substrate;

[0031] The vacuum microcavity structure encapsulates the infrared sensor unit in the vacuum environment of its inner area, and the vacuum microcavity structure includes a support shell with a release channel, an infrared anti-reflection device located above the support shell and blocking the release channel Membrane, a getter thin film inside the vacuum microca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com