Chemical sensor array having multiple sensors per well

A chemically sensitive, individual technology for sensor applications in chemical analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

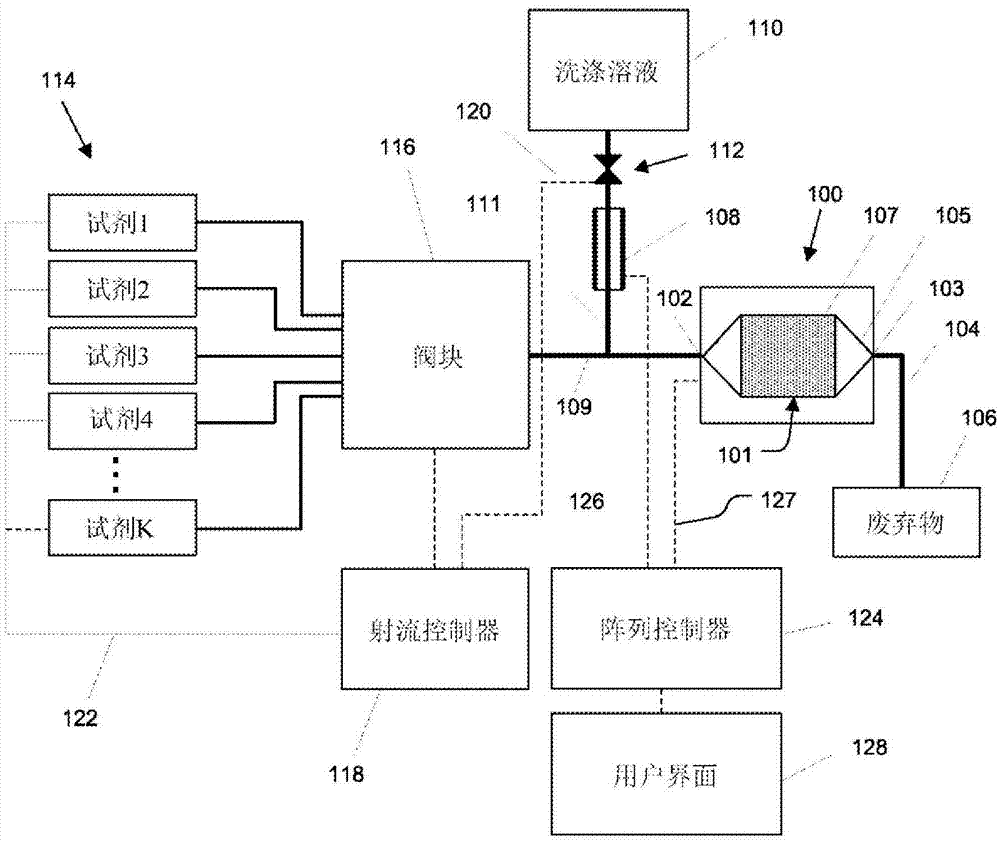

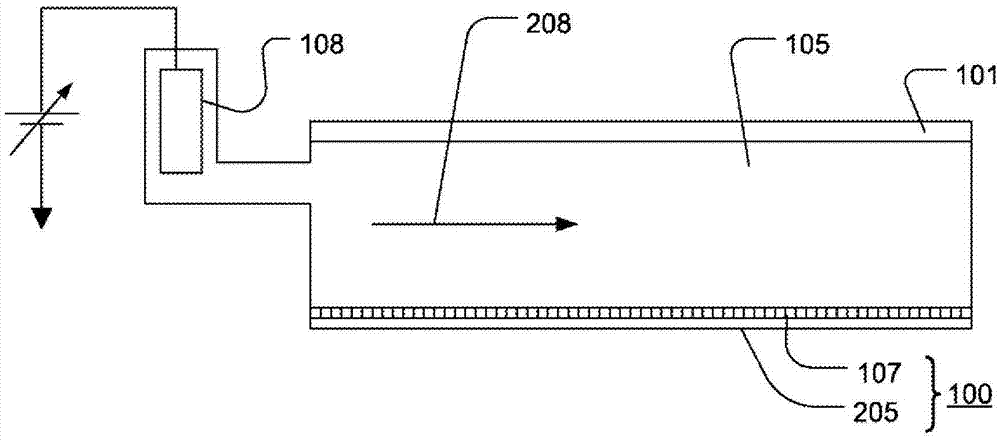

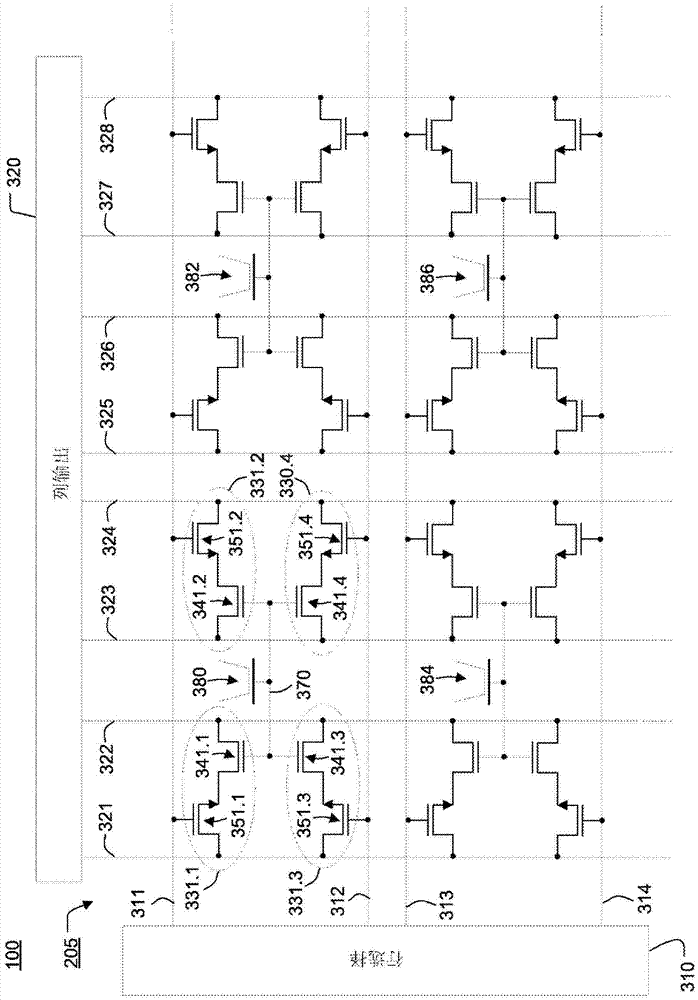

[0022] A chemical detection device is described comprising a plurality of chemical sensors for parallel detection of chemical reactions in the same operatively associated reaction zones. The multiple sensors can provide redundancy and improved accuracy in detecting properties of chemical reactions.

[0023] By utilizing multiple chemical sensors to separately detect the same chemical reaction, the individual output signals can be combined or processed to produce a composite low noise output signal. For example, individual output signals may be averaged such that the signal-to-noise ratio (SNR) of the composite output signal is improved by as much as the square root of the number of individual output signals. Additionally, the composite output signal can compensate for differences between the values of the individual output signals caused by changes in chemical sensor performance that would otherwise complicate downstream signal processing. Thanks to the techniques described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com