Noodle machine

A noodle machine and noodle drum technology, which is applied in the directions of dough extruder, mixing/kneading with vertical installation tools, etc., can solve the problem of excessive residual noodles, more remaining noodles and the effect of kneading noodles on the tooth mixer. Poor and other problems, to achieve the effect of fast output, improved surface effect, and small load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

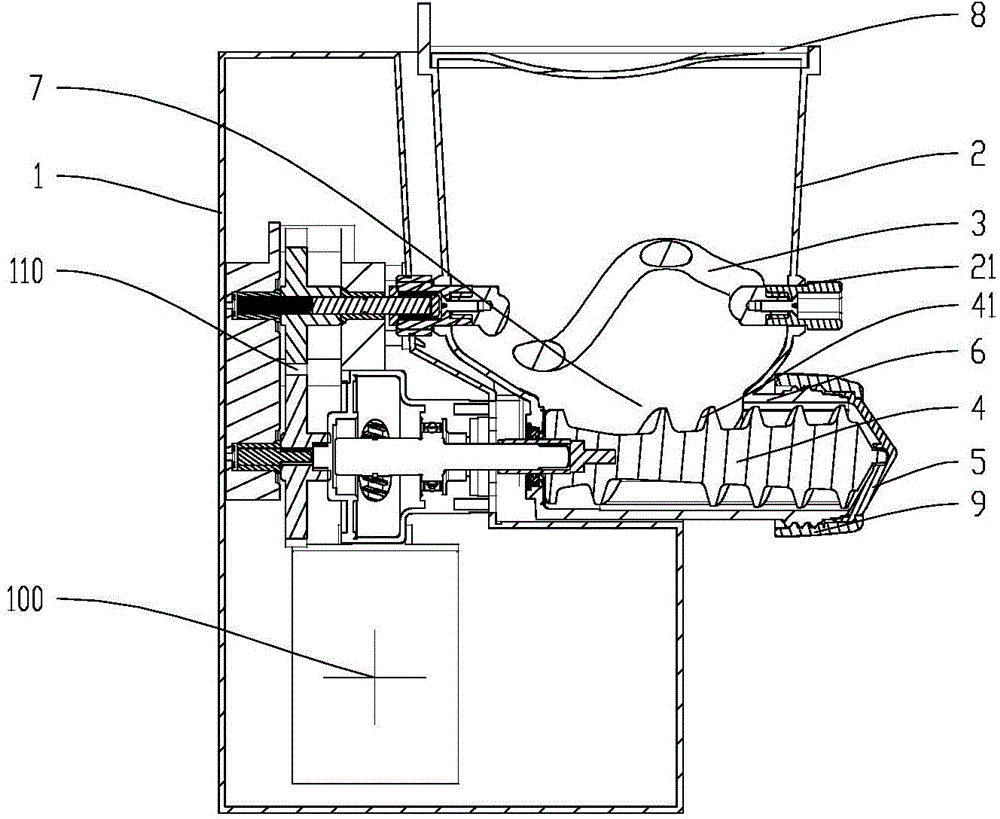

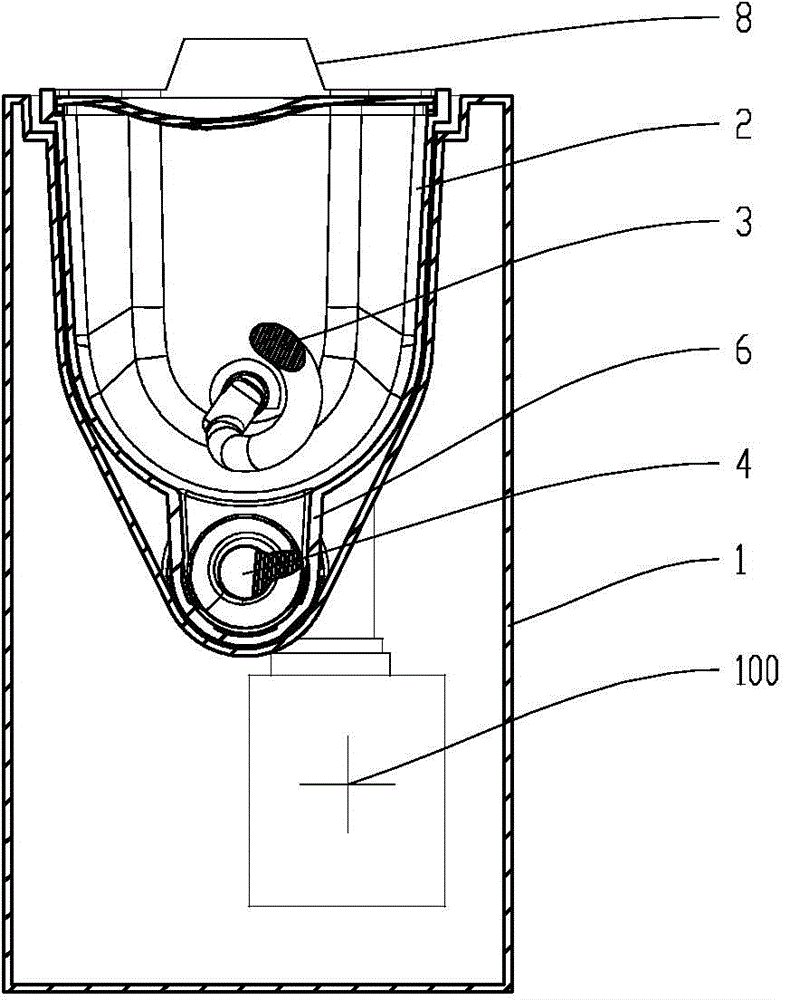

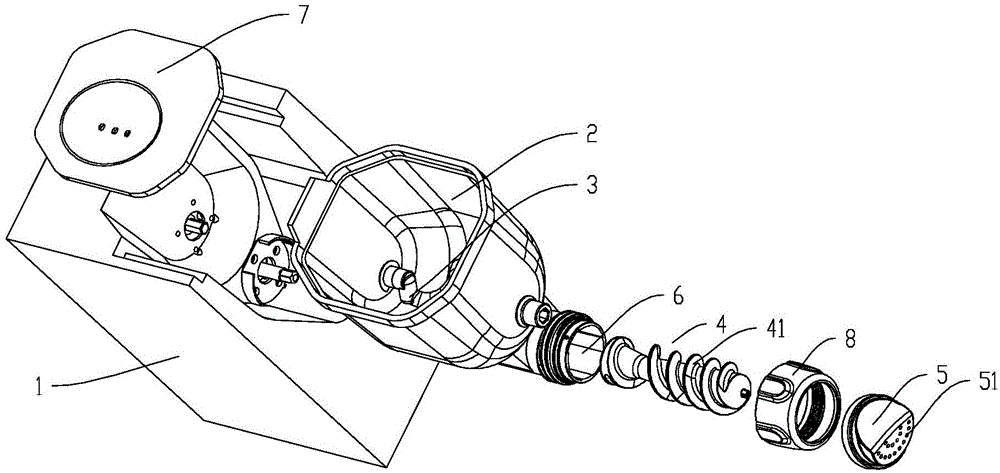

[0040] Such as figure 1 Shown in -4, the noodle machine of the present invention includes a base 1, a stirring assembly and an extruding assembly, and the stirring assembly includes a stirring cup 2 connected to the base 1 and an agitator 3, and the agitator 3 is movable And horizontally arranged in the mixing cup 2, the extruding assembly includes a screw 4, a die head 5 and a dough extruding barrel 6 connected to the stirring cup 2, the screw 4 is arranged transversely in the extruding barrel 6, and the screw 4 is set There are threads 41, the motor 100 drives the agitator 3 and the screw 4 to rotate, and the connection between the agitator cup 2 and the extruding cylinder 6 is provided with a noodle inlet 7.

[0041] Such as figure 1As shown, the motor 100 includes a first output shaft and a second output shaft, the first output shaft is located above the second output shaft, the first output shaft is connected with the agitator 3, and the second output shaft It is connec...

Embodiment 2

[0062] The difference between this embodiment and the first embodiment is that the agitator is suspended in the stirring cup.

[0063] Such as Figure 7 As shown, the rear end of the agitator 3 is connected to the motor 100 , and the front end of the agitator 3 is suspended in the stirring cup 2 . The structures and beneficial effects of other parts not described are the same as those in Embodiment 1, and will not be repeated here.

[0064] The advantage of this embodiment is that since the agitator is suspended in the air, the inner wall of the agitator cup does not need to be provided with a corresponding positioning shaft or a positioning hole, which reduces the number of accessories or reduces the manufacturing difficulty of the agitator cup.

Embodiment 3

[0066] The difference between this embodiment and Embodiment 1 is that the screws are different.

[0067] Such as Figure 8 As shown, the screw 4 is provided with a helix 41 , and the helix 41 is provided with an occlusal part for biting the dough corresponding to the noodle inlet 7 , and the occlusal part is an open groove 411 provided on the helix 41 . When extruding the dough, the dough enters the extruding barrel 6 under its own gravity and the downward pressure of the mixer 3. At this time, the screw 4 rotates, and the open groove 411 tears and squeezes the dough, so that the dough is brought in and conveyed forward. , and finally pass through the die head 5 to form the surface. The structures and beneficial effects of other parts not described are the same as those in Embodiment 1, and will not be repeated here.

[0068]The advantage of this embodiment is that, by setting the occlusal portion on the screw rod for occlusal dough, it is convenient for the dough to be con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com