Sunstroke preventing and cooling working cap with fans

A heatstroke prevention and cooling, working technology, applied to hats, hat products, clothing, etc., can solve the problems of ineffective heatstroke prevention and cooling, and achieve the effect of simple structure and good comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

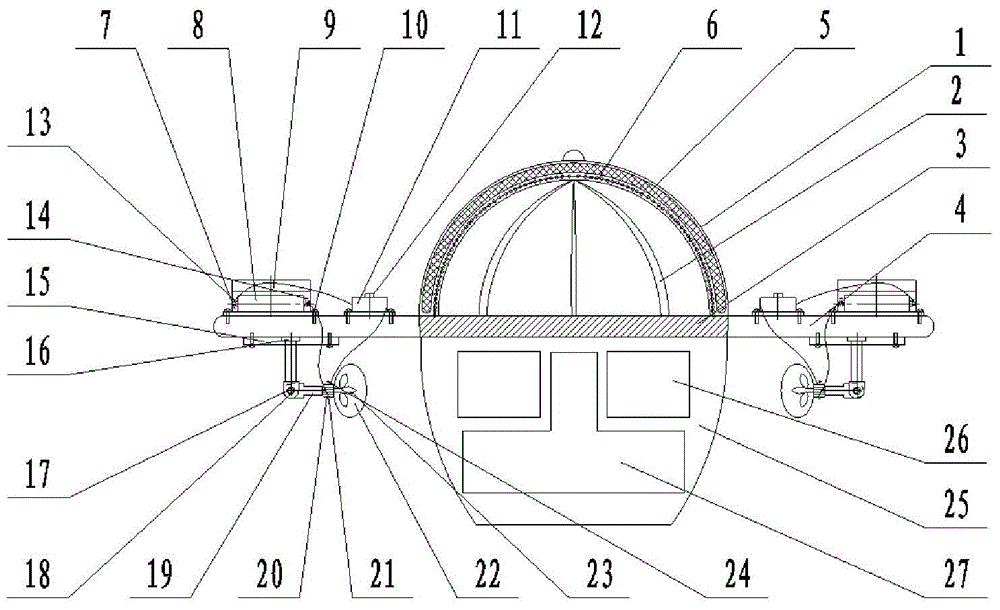

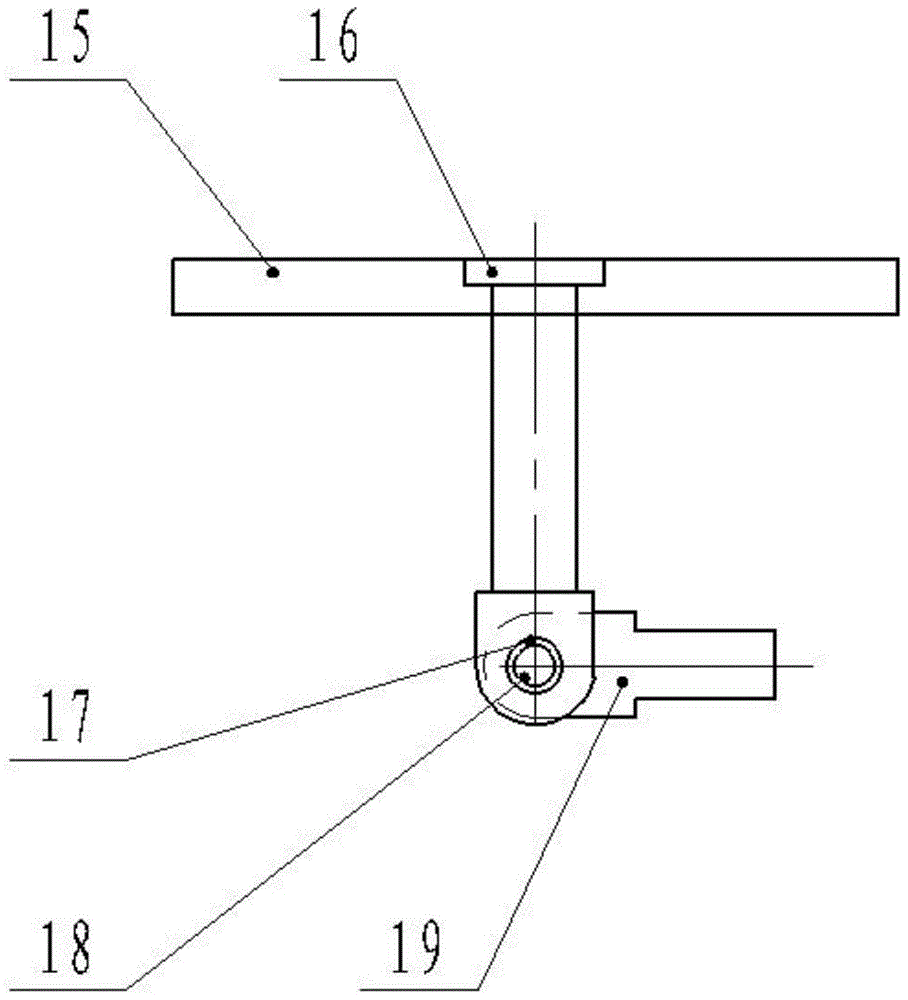

[0015] like figure 1 and figure 2 The shown heatstroke prevention and cooling work cap with a fan includes a work cap device, a power supply device, a switch device, a rotating auxiliary device, and an electric fan device.

[0016] The working cap device is provided with a cap shell 1, a support frame 2, a brim 3, a visor 4, a cold water inner baffle 5, a zipper 6, a front baffle 25, a glass eye mask 26, and an ice pack 27; the support frame 2 is arranged inside the cap shell 1 , the hat brim 3 is set below the cap shell 1, the cap bill 4 is set around the cap brim 3, the cold water inner block 5 is placed inside the cap shell 1, and the zipper 6 is fixed, and the bottom of the hat brim 3 is provided with a front cover 25, and the front cover 25 There are glass eyecups 26 and ice packs 27 on it. The ice pack 27 is attached to the inner surface of the front cover 25 and is evenly distributed, which effectively increases the effect range and prevents discomfort caused by loca...

Embodiment 2

[0022] A heatstroke prevention and cooling work cap with a fan comprises a work cap device, a power supply device, a switch device, a rotating auxiliary device and an electric fan device.

[0023] The working cap device is provided with a cap shell 1, a support frame 2, a brim 3, a visor 4, a cold water inner baffle 5, a zipper 6, a front baffle 25, a glass eye mask 26, and an ice pack 27; the support frame 2 is arranged inside the cap shell 1 , a brim 3 is arranged below the cap shell 1, and a visor 4 is arranged around the brim 3. A cold water inner baffle 5 is placed inside the cap shell 1, which is fixed by a zipper 6. A front baffle 25 is arranged under the brim 3. The front baffle 25 is provided with a glass eye mask 26 and an ice pack 27. The glass eye mask 26 is made of tempered glass and has a firm surface. Not easy to be damaged, the ice pack 27 is attached to the inner surface of the front cover 25, and the distribution is uniform, which effectively increases the ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com