Table top injection molding edge covering technology

A process and edge wrapping technology, which is applied in the field of desktop injection molding edge wrapping technology, can solve the problems of poor waterproof performance, swelling of the board, and personnel injury, etc., and achieve the effects of not easy to fall off, prolonging the service life, and good edge waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] A desktop injection molding edge wrapping process, comprising the following steps:

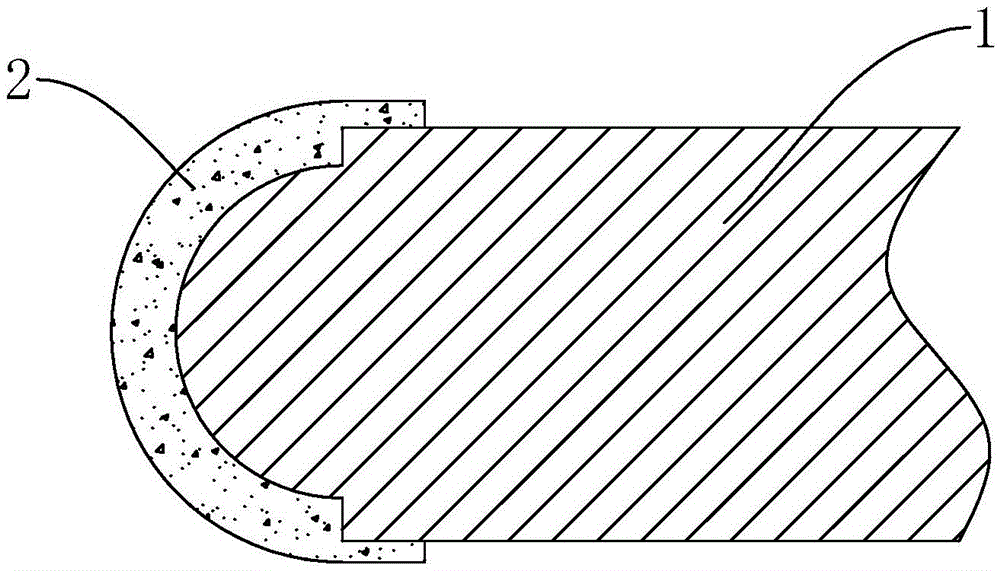

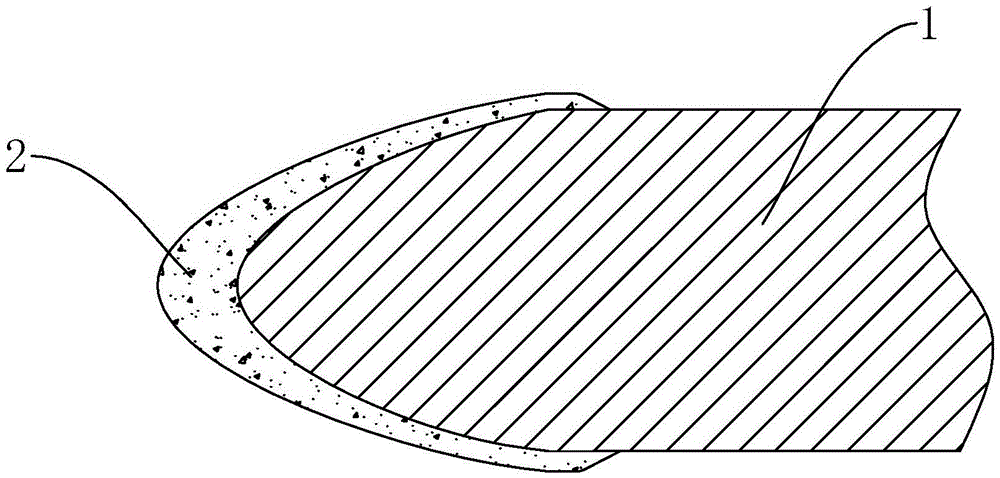

[0023] Step 1. Cutting the desktop board 1, cutting the wooden board to the shape required by the desktop board 1. In this embodiment, a 5mm shaving veneer is used, the tolerance range is within ±0.2mm, and it is cut according to electronic cutting Cut to the required shape, such as square, rectangle, circle, ellipse, etc., only 2 pieces can be opened at a time, the chipping is within ≤2mm, and the length and width error is within ±0.5mm;

[0024] Step 2, processing the edge of the desktop board 1, processing the edge of the desktop board 1 to a convex shape;

[0025] Wherein, step 2 includes the following sub-steps:

[0026] Step 2.1. Engraving lines and drilling mold positioning holes on the edge of desktop board 1 by CNC machine tools, depth = 2.5mm, line wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com