Combined waste gas filtering tank

An exhaust gas filtration and combined technology, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of inconvenient use and maintenance, incomplete exhaust gas filtration, and bulky equipment, etc., to improve the filtration effect, simple structure and volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below in conjunction with the accompanying drawings.

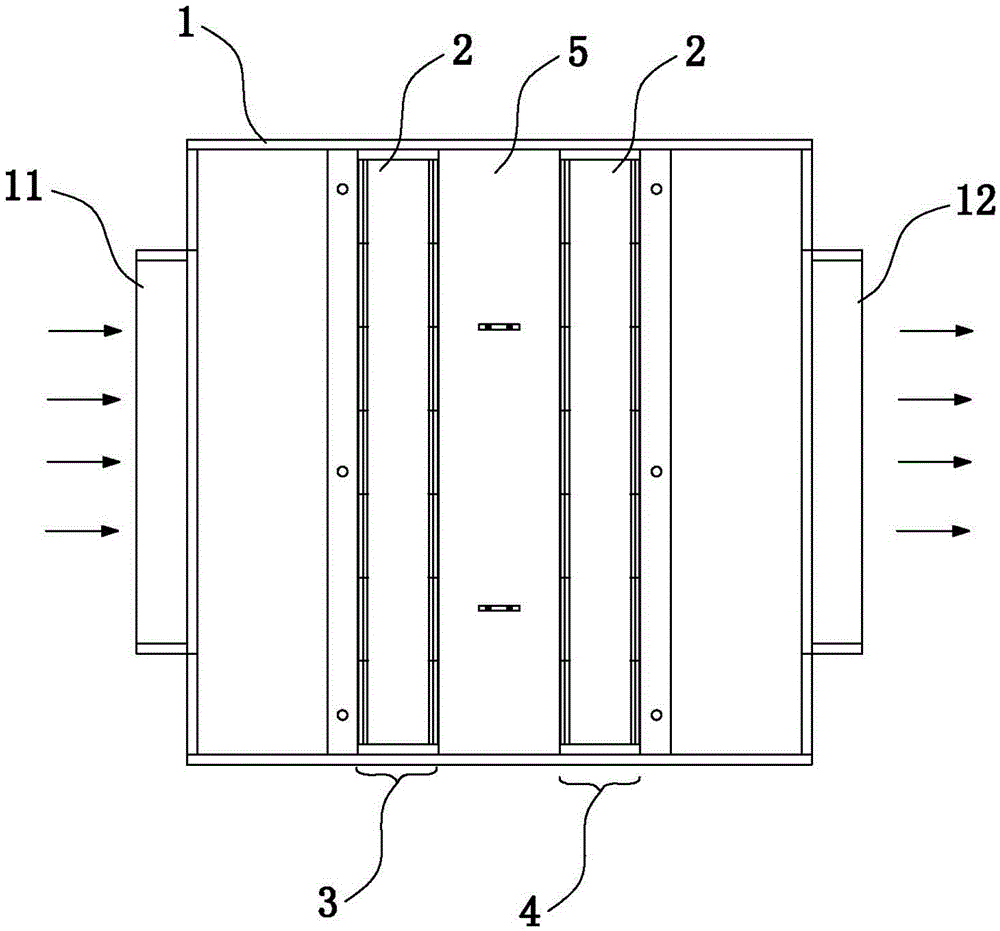

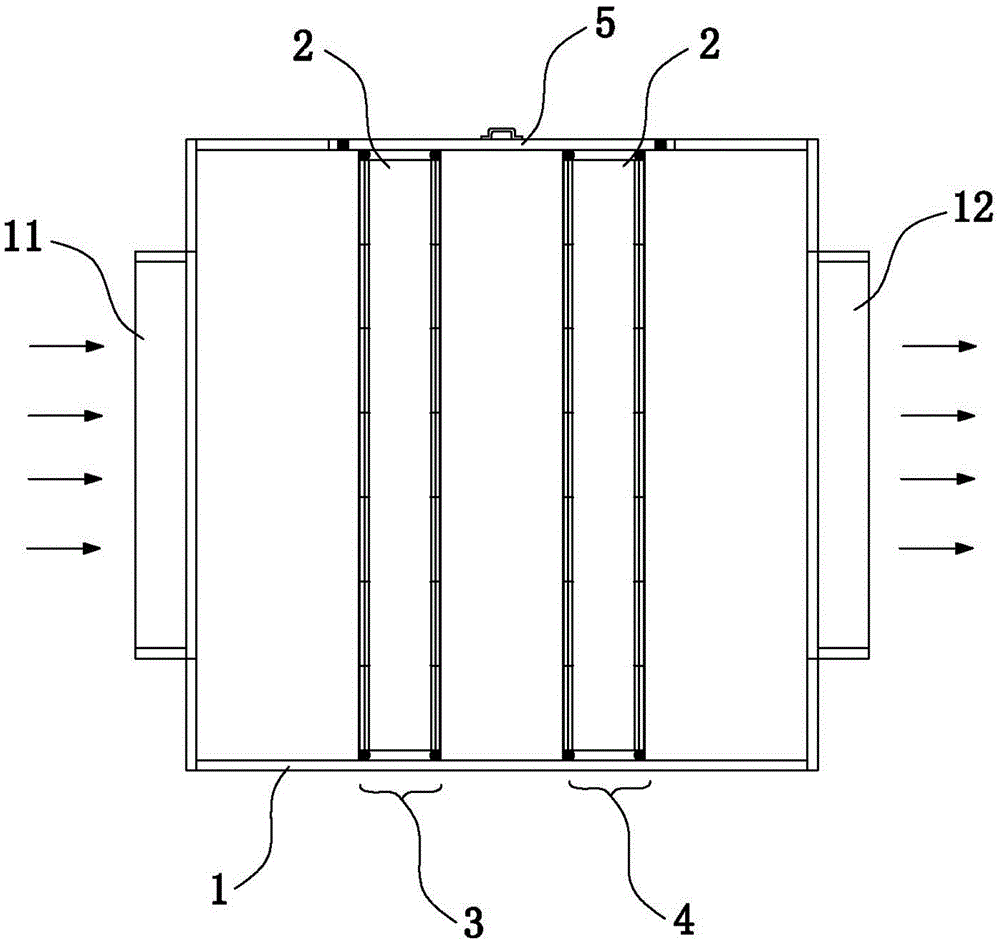

[0016] refer to figure 1 As shown, one embodiment of the present invention is a combined exhaust gas filter box, which includes a box body 1, and the box body 1 is preferably welded on both sides by PP (polypropylene) boards, thereby reducing the volume of the filter box , and reduce its overall quality; as shown in the figure, the aforementioned box 1 is provided with an air inlet 11 and an air outlet 12, and more importantly, a drawer for installing a filter core material is provided inside the aforementioned box 1 The drawer-type spacer 2 adopts a structure similar to that of a drawer, and is installed with the slide rail inside the box body, which can be easily pushed and pulled; and the drawer-type spacer 2 needs to be placed in the aforementioned air inlet 11 and air outlet Between 12; at the same time, in order to meet the demand for composite filtration and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com