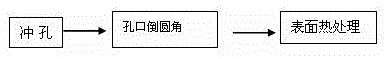

Plunger hole rounding process for automobile engine

An automotive engine and corner rounding technology, applied in the field of mechanical processing, can solve the problems of quality risk, increase processing cycle, long processing cycle, etc., and achieve the effect of shortening production cycle, prolonging production cycle and stable processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The invention provides a rounding process for plunger holes for automobile engines:

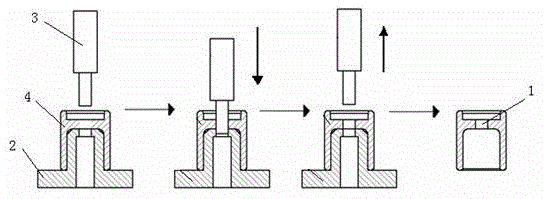

[0033] Such as figure 1 As shown, the punching punch 3 is installed on the working table of the punching equipment and the stroke is adjusted. The blank plunger is accurately placed on the punching die 2 and the punching equipment is started. The punching punch 3 moves down quickly with the working table of the punching equipment. The blank is forcibly punched through to form a hole with the same cross-sectional shape as the punching punch 3, and then the punching punch is quickly returned to the original point with the upper worktable, and the plunger blank hole is processed.

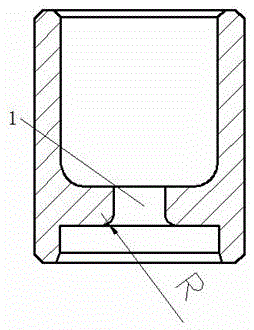

[0034] Such as figure 2 As shown, the rounding step of the hole of the plunger blank is basically the same as the punching step. The hole rounding punch 5 is installed on the worktable of the punching equipment and the stroke is adjusted, and the hole punched in the punching step The plug blank 4 is correctly pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roundness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com