Chute assembly for aluminum casting system

A chute, aluminum technology, used in casting equipment, manufacturing tools, equipment for feeding molten metal into casting molds, etc. It is easy to promote and apply, and the operation saves time and effort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

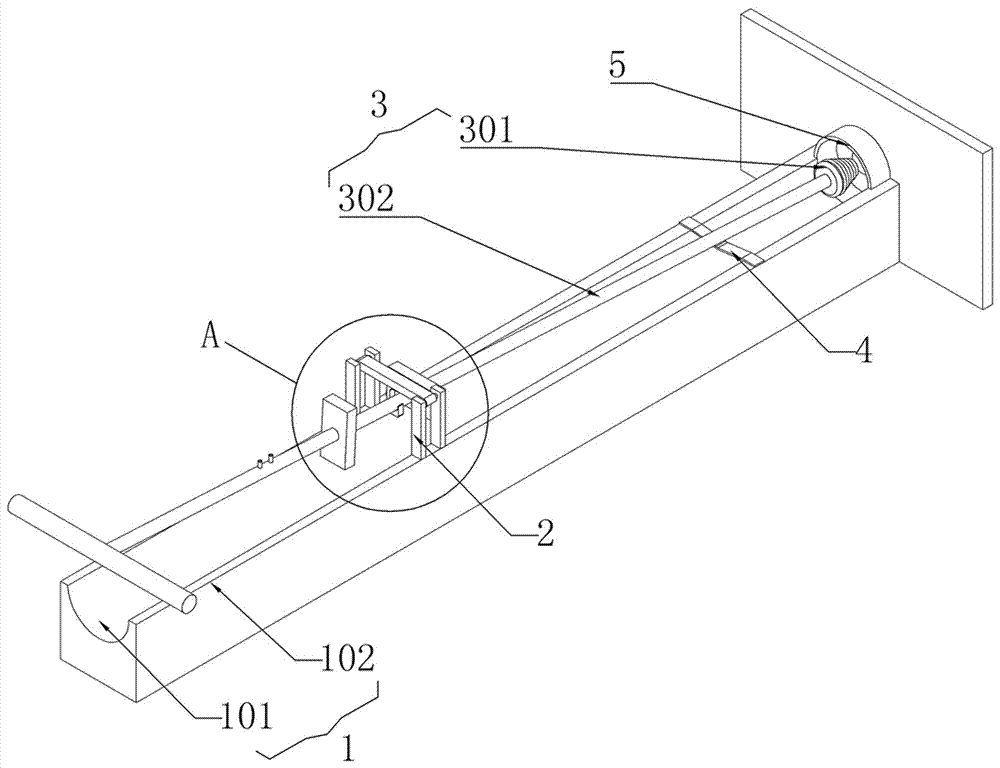

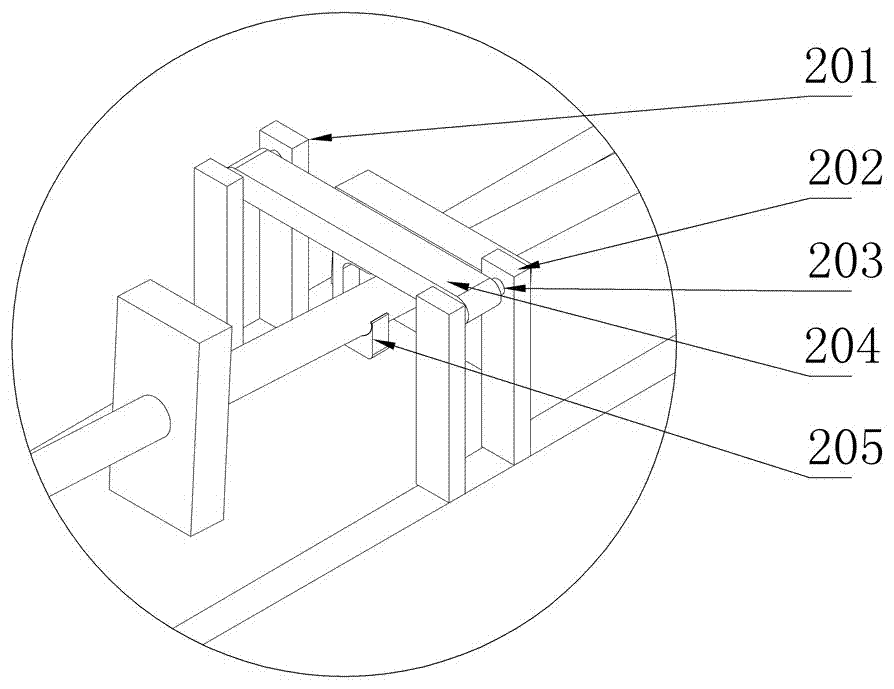

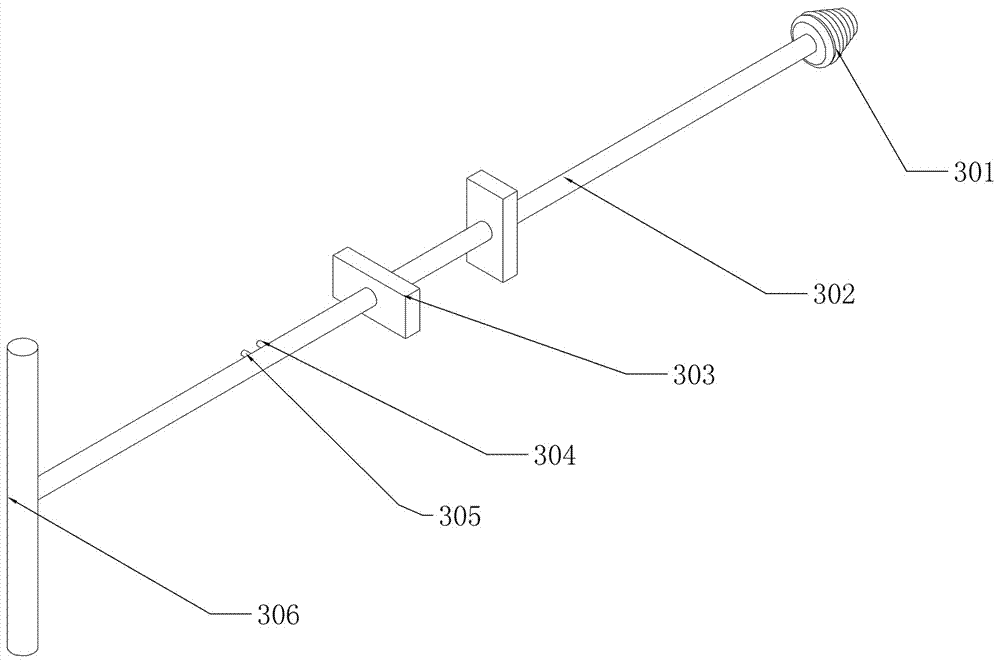

[0019] Embodiment 1: as Figure 1~2 Shown: the chute assembly for the aluminum casting system, including the chute 1, the stabilizing device 2 fixedly connected to the top of the chute 1, and the blocking device 3 connected with the furnace eye 5; the blocking device 3 includes a long rod 302 and a long rod 302 The plug 301 at the end, the chute 1 includes an arc-shaped plane bottom 101 and a side wall 102 of the flow channel integrated with the bottom 101. The side wall 102 of the flow channel is provided with a support plate 4 at a position close to the exit of the furnace hole 5 , the long rod 302 is positioned at the top of the support plate 4; the stabilizing device 2 comprises a left frame 201 positioned at the top of the chute side wall 102, a right frame 202 and a pressing plate 204 hinged on the right frame 202, the pressing plate 204 is connected to the left frame 201 The connecting rod 203 is fastened, and the bottom of the pressing plate 204 is welded with a C-shap...

Embodiment 2

[0021] The difference between embodiment 2 and embodiment 1 is that the diameter ratio between adjacent circular threads is 1:1.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com