Autonomous navigation harmful gas detecting robot

A harmful gas and autonomous navigation technology, applied in the field of detection and detection robots, can solve the problems of the robot’s temperature rise, the detection work cannot be carried out, and the cracks and leaks cannot be directly found, so as to achieve the effect of a comprehensive camera perspective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

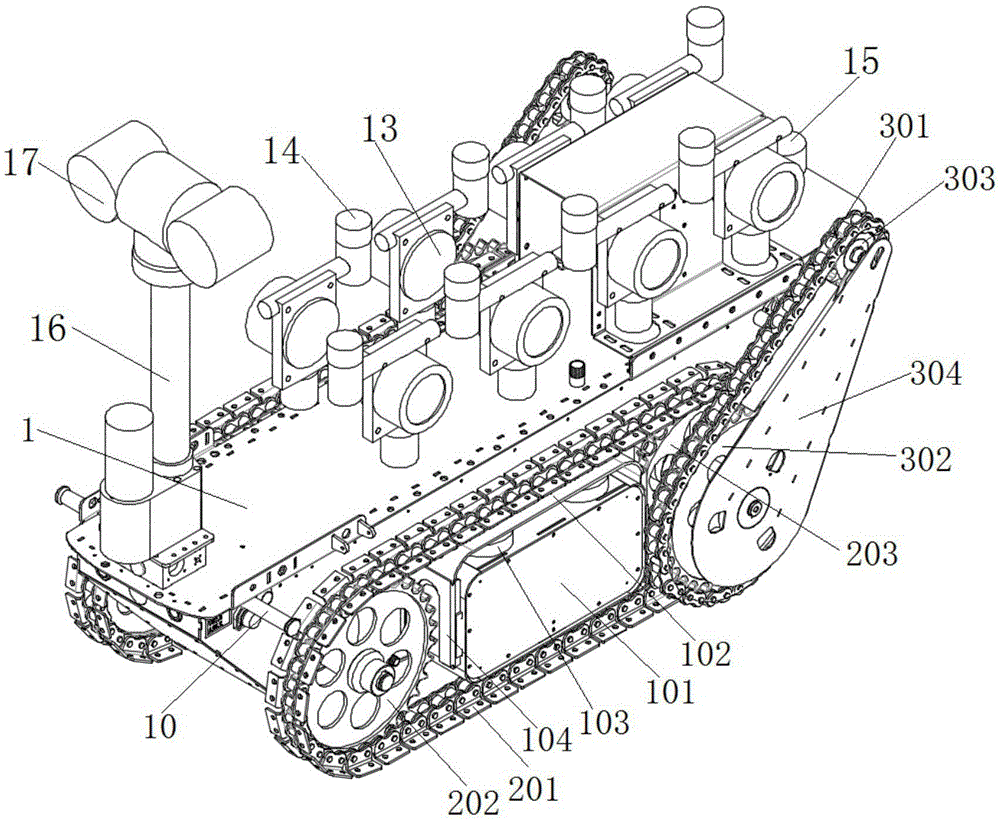

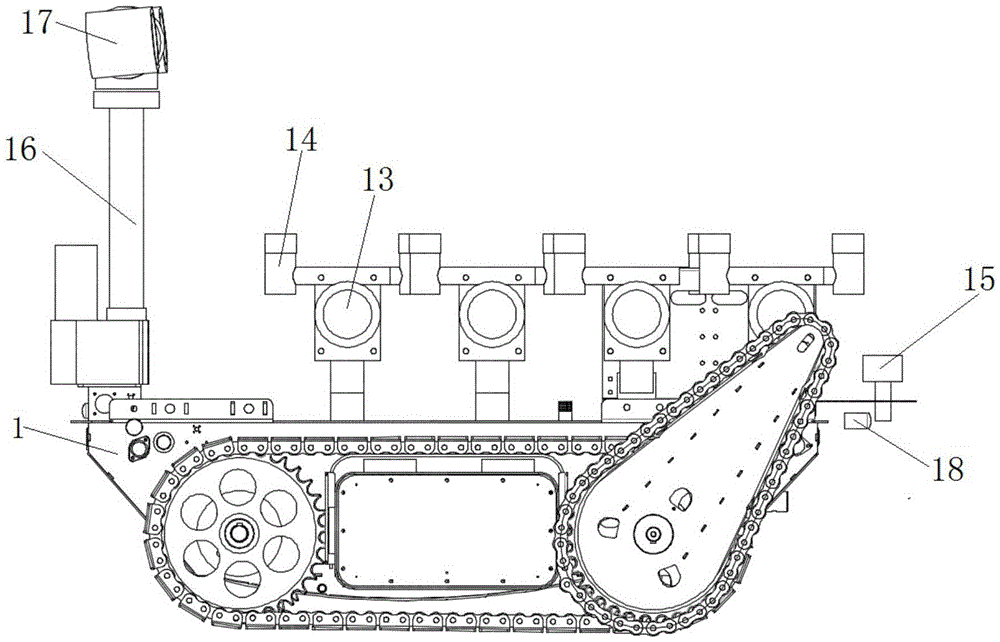

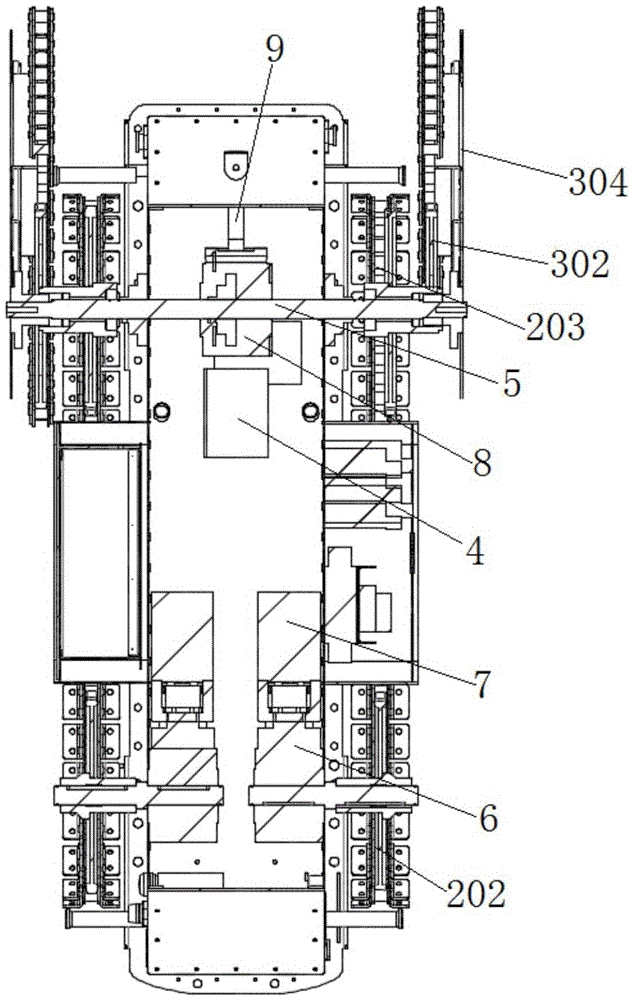

[0034] combine figure 1 , figure 2 and image 3 , the harmful gas detection robot of a kind of self-navigation of present embodiment, comprises wheel-track robot platform, comprises chassis cabin body 1 and is arranged on the crawler belt walking mechanism on the left and right sides of chassis cabin body 1, and chassis cabin body in this embodiment The front and rear sides of 1 are inwardly inclined slopes to improve the obstacle-surmounting ability of the robot platform; in order to facilitate the handling of chassis cabin 1, lifting handles 10 are provided at the front and rear positions of the left and right side panels of chassis cabin 1, and In order to facilitate the carrying of fuses, emergency medicines and emergency equipment, the lifting handle 10 is a hollow tube, and the opening of the hollow tube is threadedly connected with an end cover; the crawler walking mechanism includes a chassis anti-corrosion metal track 201, a chassis driving wheel 202 and a side with...

Embodiment 2

[0040] The basic structure of a self-navigating harmful gas detection robot of this embodiment is the same as that of Embodiment 1, except that the monitor 17 is an infrared thermal imager, which can find pipeline leakage points, ignition points or waiting points through subtle temperature changes. save people.

Embodiment 3

[0042] The basic structure of a self-navigating harmful gas detection robot of this embodiment is the same as that of Embodiment 1, except that the monitor 17 is a pan-tilt camera.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com