A 3D printer that can automatically peel off models and print continuously

A 3D printer, automatic peeling technology, applied in manufacturing, additive processing, liquid material additive processing, etc., can solve the problems of 3D printers not suitable for mass production, the impact of mass production time, and the safety of operators, to avoid The effect of model damage, easy maintenance and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

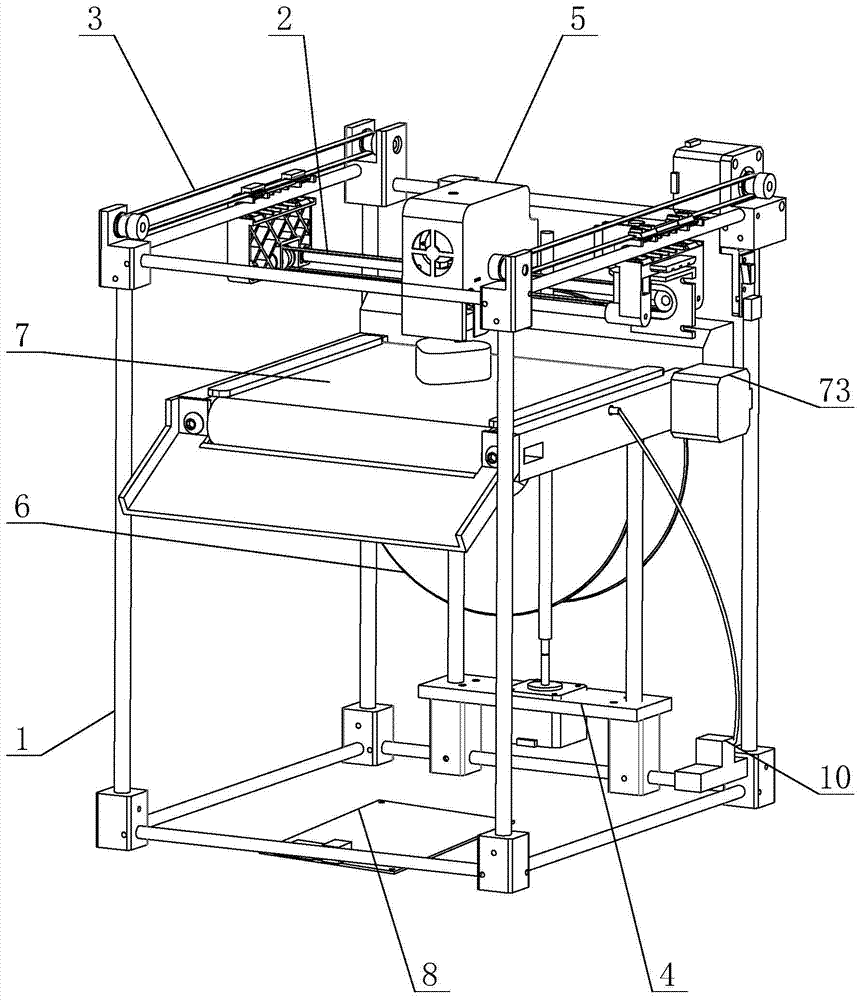

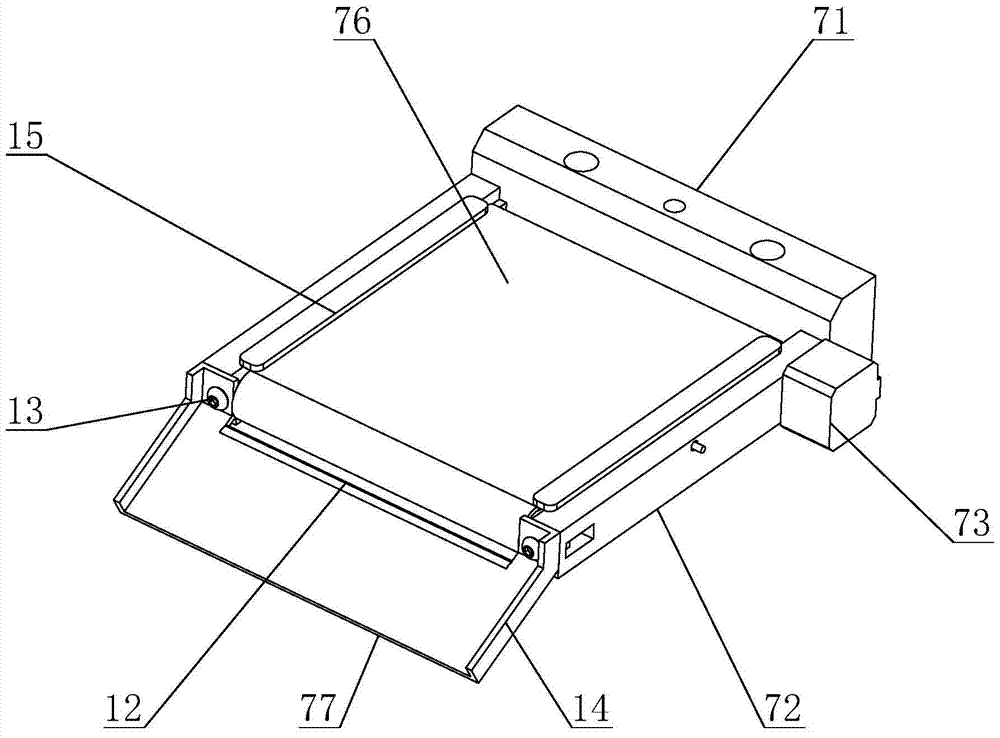

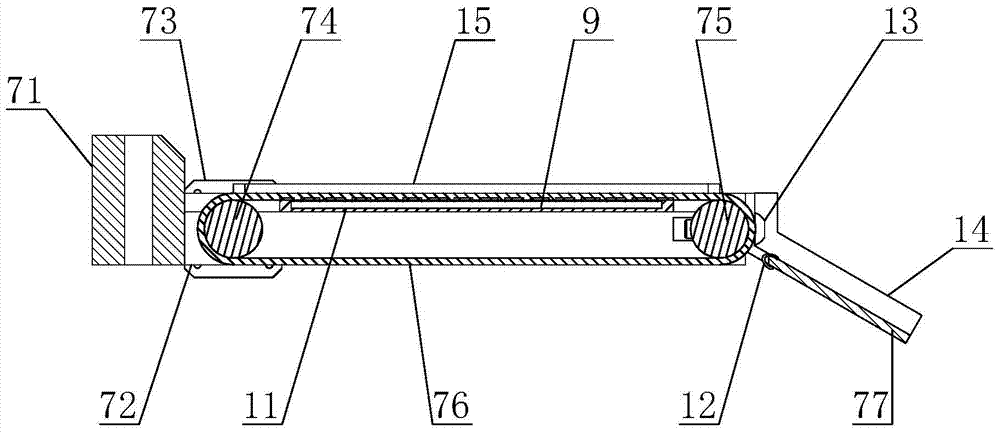

[0042]A 3D printer that can automatically peel off models and print continuously, including a frame 1, an X-axis motion mechanism 2, a Y-axis motion mechanism 3, a Z-axis motion mechanism 4, a material spraying mechanism 5, printing consumables 6, a printing platform 7, and a control device 8. The Y-axis motion mechanism 3 is installed on the top of the frame 1, the X-axis motion mechanism 2 is located on the top of the frame 1 and connected with the Y-axis motion mechanism 3, and the spraying mechanism 5 is installed on the X-axis motion mechanism 2, The Z-axis motion mechanism 4 is located on one side of the frame 1 , and the printing platform 7 is installed on the Z-axis motion mechanism 4 . The printing platform 7 includes a base 71 connected to the Z-axis motion mechanism 4, a platform frame 72 fixedly connected to the base 71, a platform motor 73 is arranged at one end of the platform frame 72, and a driving motor 73 is installed on the output shaft of the platform motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com