Oil hydraulic press jacking device

A jacking device and hydraulic press technology, which is applied to presses, manufacturing tools, etc., can solve the problems of reducing the service life of hydraulic presses, declining working conditions of hydraulic presses, troublesome machine maintenance, etc., so as to avoid standstill, ensure normal work, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

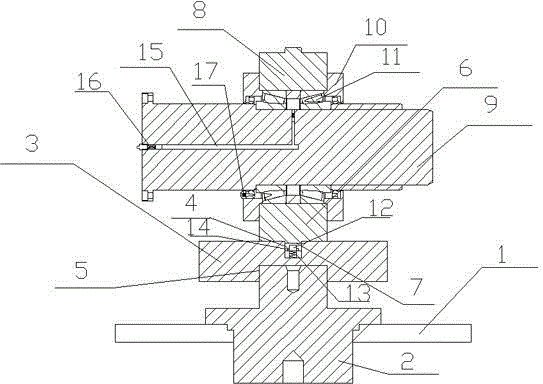

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] A jacking device for a hydraulic press, comprising a frame 1, a lifting cylinder 2 and a railed lifting plate 3, a lifting cylinder 2 is arranged in the middle of the frame 1, the bottom of the lifting cylinder 2 is located in the frame 1, and the top of the lifting cylinder 2 is a boss structure , the rail lifting plate 3 is strip-shaped, and the rail lifting plate 3 is provided with a groove, the groove is a double-sided groove, the width of the upper groove 4 is less than the width of the lower groove 5, and the upper groove 4 and the roller The belts 6 are connected to each other, and the roller belt 6 is provided with a protruding connector 7, and the protruding connector 7 is embedded in the upper groove, and the upper part of the upper groove 4 is provided with a rail roller 8, and the rail roller 8 is a circular roller. Rail roller assembly mechanism 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com