Linear magnetic drive device, screen printing system where it is located, and method of use

A magnetic transmission, linear technology, applied in screen printing machines, printing devices, printing and other directions, can solve the problems of low transmission accuracy and low work efficiency, and achieve the effect of simplified mechanism, high work efficiency and low friction force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

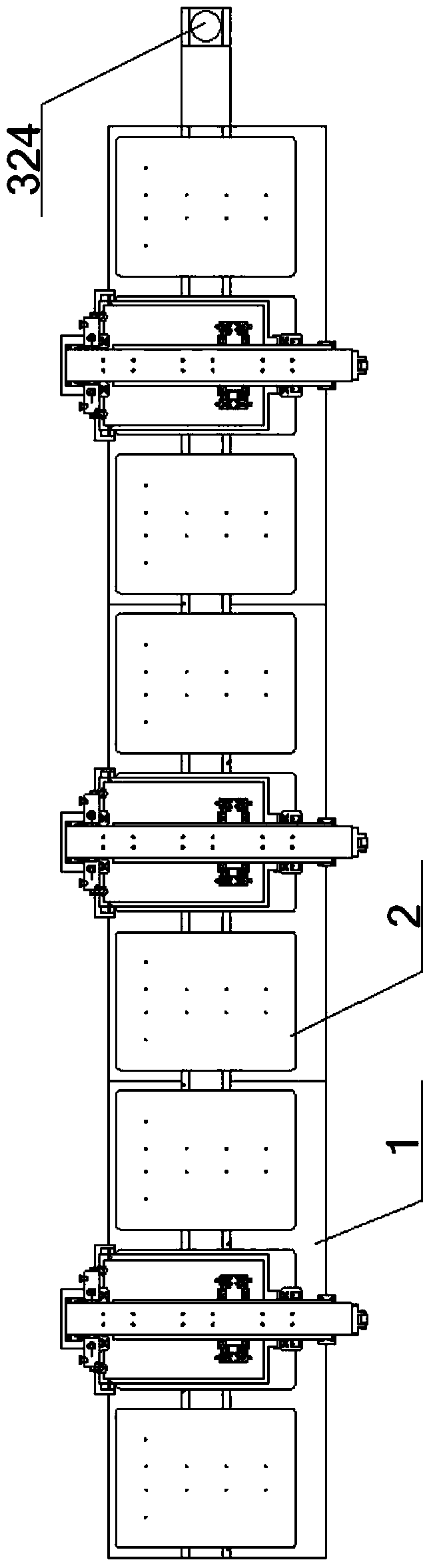

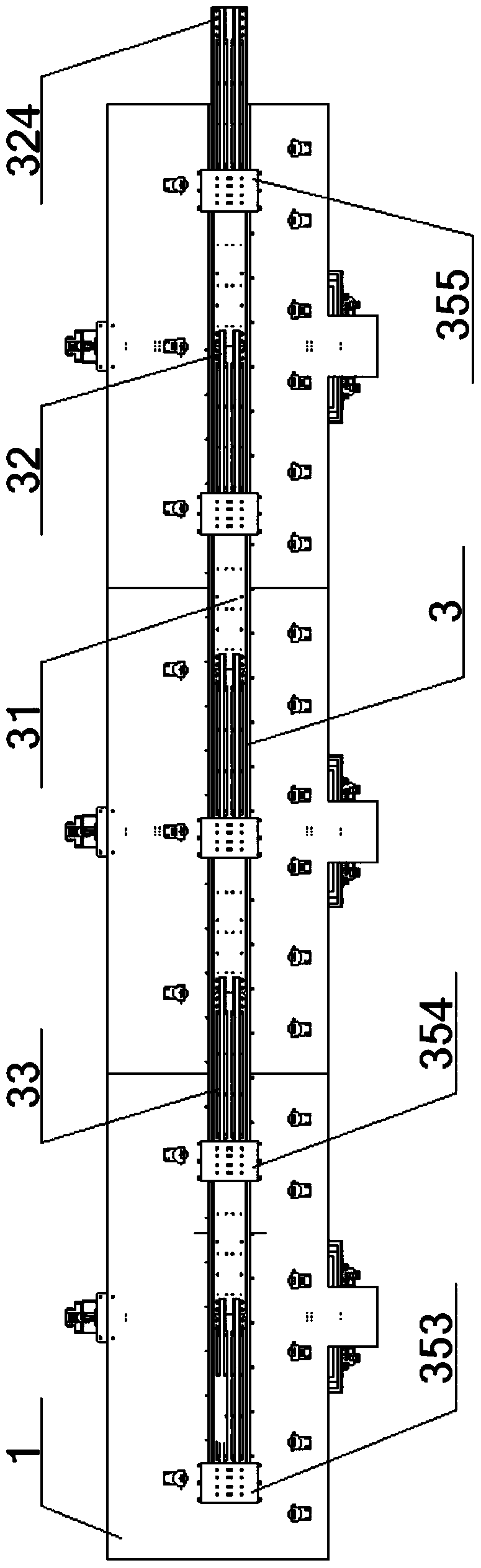

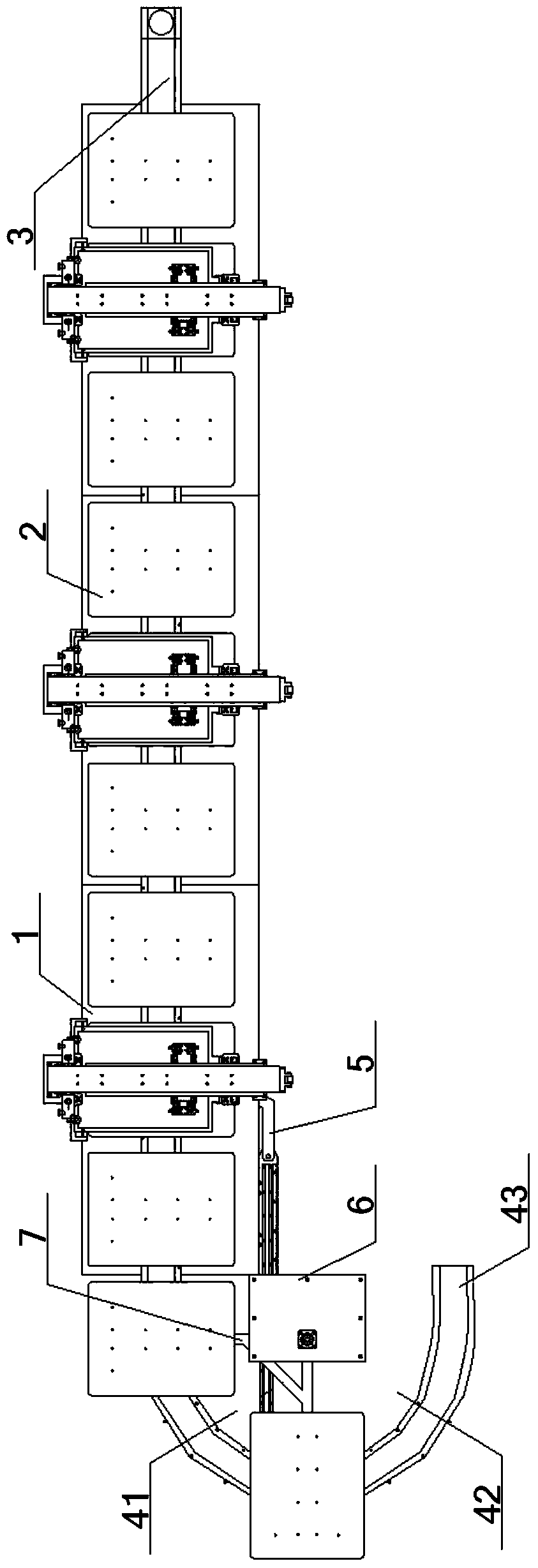

[0062] see figure 1 – Figure 12 , a linear magnetic transmission device, comprising a linear table 1 and a plurality of printing table 2 arranged on it, the printing table 2 rolls along the top surface of the linear table 1, and a printing table is arranged below the linear table 1 The linear driving device 3 of the plate 2; the linear driving device 3 includes a slide plate 31 and a plurality of electromagnetic coils 32, a linear guide rail 33, a rail seat 34, and a support seat 35, and the bottom of the electromagnetic coil 32 is connected to the top of the slide plate 31. The bottom surface of the slide plate 31 is connected with the top of the linear guide rail 33, the bottom of the linear guide rail 33 is slidably fitted with the guide rail seat 34 below it, the bottom of the guide rail seat 34 is connected with the bottom plate of the support seat 35, and the support seat 35 The side plate is connected with the linear table top 1; the electromagnetic coil 32 is evenly ...

Embodiment 2

[0066] Basic content is the same as embodiment 1, the difference is:

[0067] The support seat 35 is a U-shaped structure, including a seat bottom plate 351 and a seat side plate 352 vertically connected to its two ends, the top surface of the seat bottom plate 351 is connected with the bottom of the guide rail seat 34, and the seat side plate 352 is connected to the seat above it. Straight table 1 is connected. There are three rollers 24 in one printing platen 2 , wherein two rollers 24 are located on the same side of the permanent magnet 23 , and the other roller 24 is located on the other side of the permanent magnet 23 .

Embodiment 3

[0069] Basic content is the same as embodiment 1, the difference is:

[0070] see figure 1 – Figure 12 , the first two support seats 35 near the head end of the linear table top 1 on the linear drive device 3 are respectively the first support seat 353 and the first two support seats 354, and the support seat 35 at the tail end of the linear table top 1 is the rear support seat 355, the previous support base 353, the front two support bases 354 are respectively provided with the previous electromagnetic coil 321, the first three electromagnetic coils 323, the previous support base 353 is provided with the previous guide rail seat 341 to be consistent with the previous The linear guide rail 331 is slidably fitted, the head end of the preceding linear guide rail 331 is flush with the previous guide rail seat 341, and the top surface of the slide plate 31 directly above the tail end of the preceding linear guide rail 331 is connected with the first two electromagnetic coils 322...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com