Test device and test method for pressurized column leaching of uranium ore by CO2+O2

A test method and test device technology, applied in the field of uranium mining and smelting, can solve problems such as difficult to obtain satisfactory results, unstable operation, complex structure, etc., and achieve a wide range of applicable pressures, strong leaching regularity, and stable leaching process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

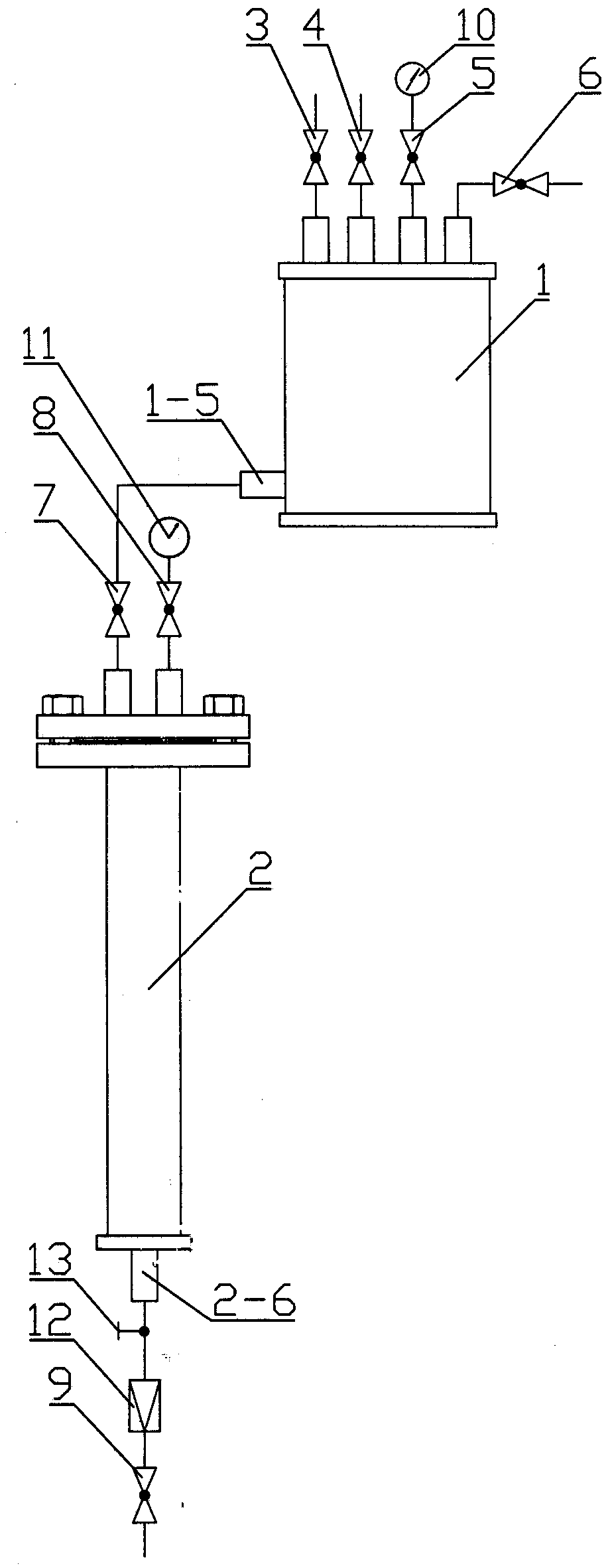

[0025] Using CO 2 +O 2 Test device for pressurized column leaching of uranium ore, including liquid storage tank 1, leaching column 2, first ball valve 3, second ball valve 4, third ball valve 5, fourth ball valve 6, fifth ball valve 7, sixth ball valve 8 , The seventh ball valve 9, the first pressure gauge 10, the second pressure gauge 11, the pressure reducer 12 and the right-angle ball valve 13.

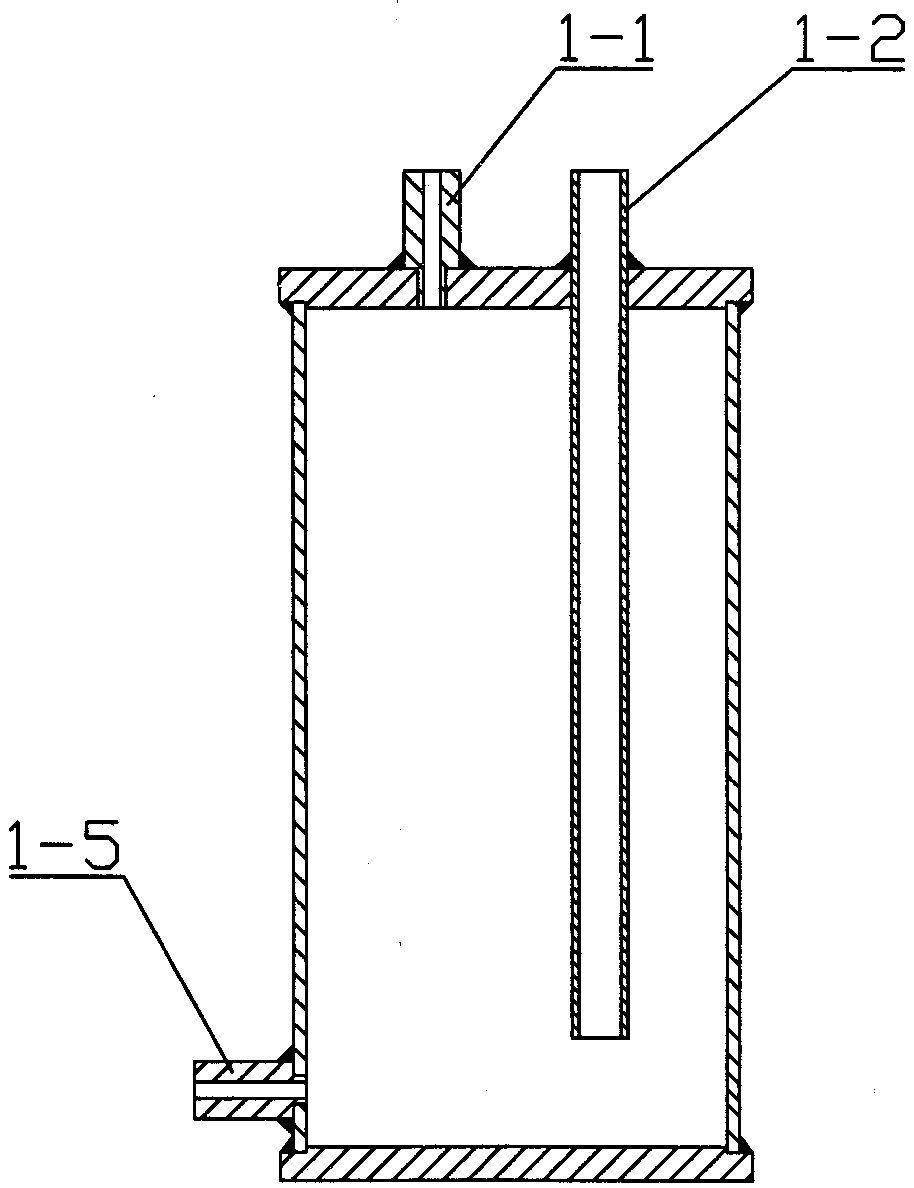

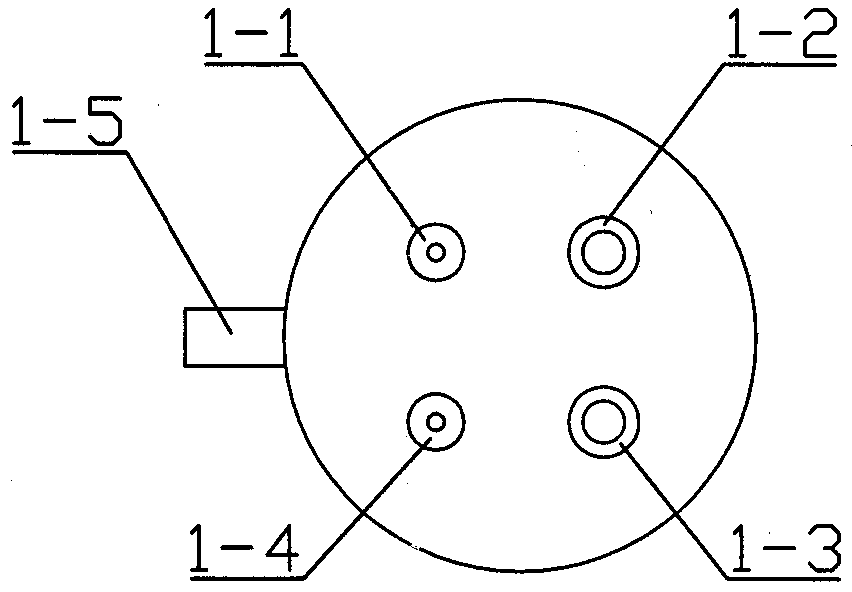

[0026] The liquid storage tank 1 is a cylindrical barrel with both ends closed, and the upper end plate of the liquid storage tank 1 is provided with water inlet pipe joints 1-1, O 2 Intake pipe 1-2, CO 2 Intake pipe 1-3 and first pressure gauge connector 1-4, one end of the third ball valve 5 is installed on the first pressure gauge connector 1-4, the first pressure gauge 10 is installed on the other end of the third ball valve 5, the fourth The ball valve 6 is installed on the water inlet pipe joint 1-1, and the first ball valve 3 and the second ball valve 4 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com