Spontaneous-combustion active ferrous sulfide gaseous phase passivation device and method

The technology of ferrous sulfide and gas phase passivation is applied in the treatment field of inhibiting spontaneous combustion of active ferrous sulfide, which can solve the problems of high risk, corrosion of equipment, pollution of the environment by heavy metal ions, etc., and achieves the effect of simple and convenient operation and low cost.

Inactive Publication Date: 2016-04-06

BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The current commonly used passivation method will produce heavy metal ions to pollute the environment, and the oxidant will corrode the equipment, and the operation is complicated and dangerous

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

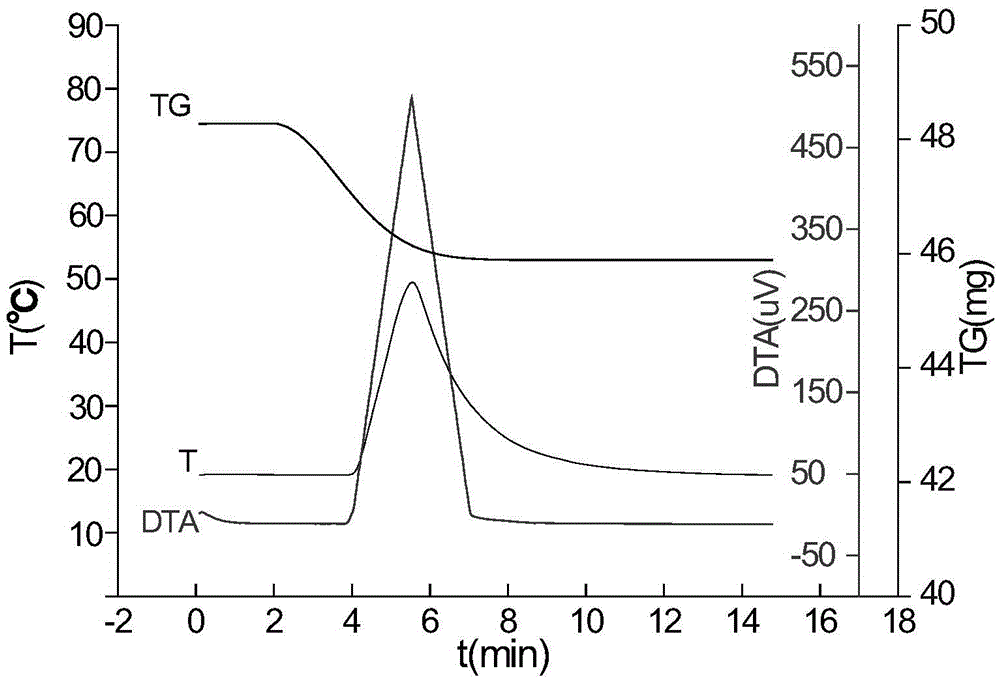

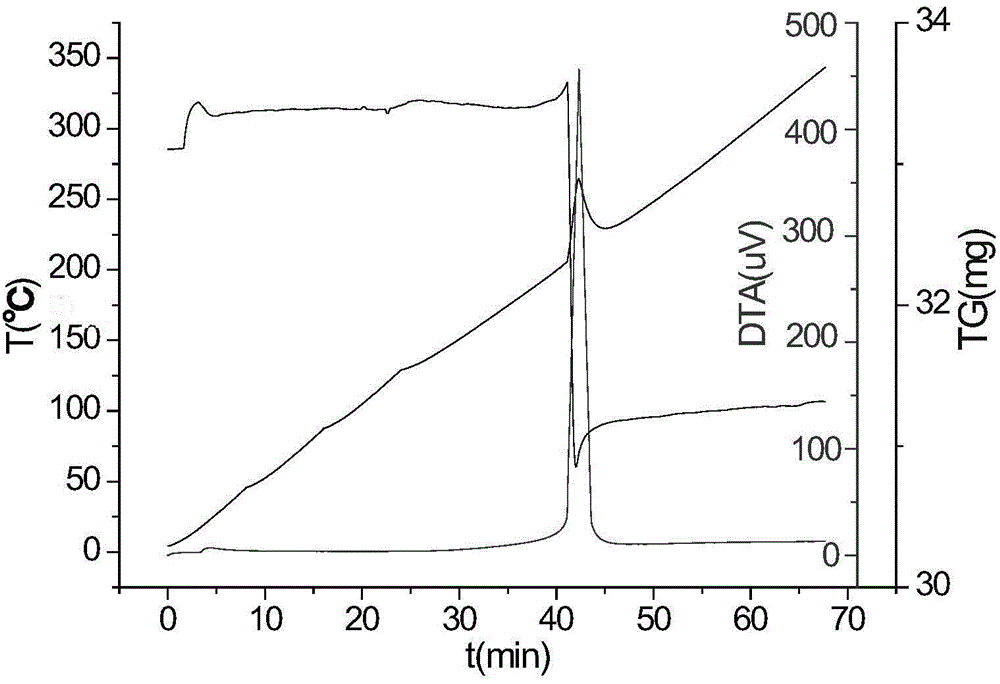

[0063] Adopt passivation device of the present invention, press passivation method of the present invention, ferrous sulfide sample is carried out passivation treatment, the DTA-TG figure after passivation is as follows figure 2 As shown, the reaction temperature is 210°C, and the reaction heat is 425KJ / mol.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

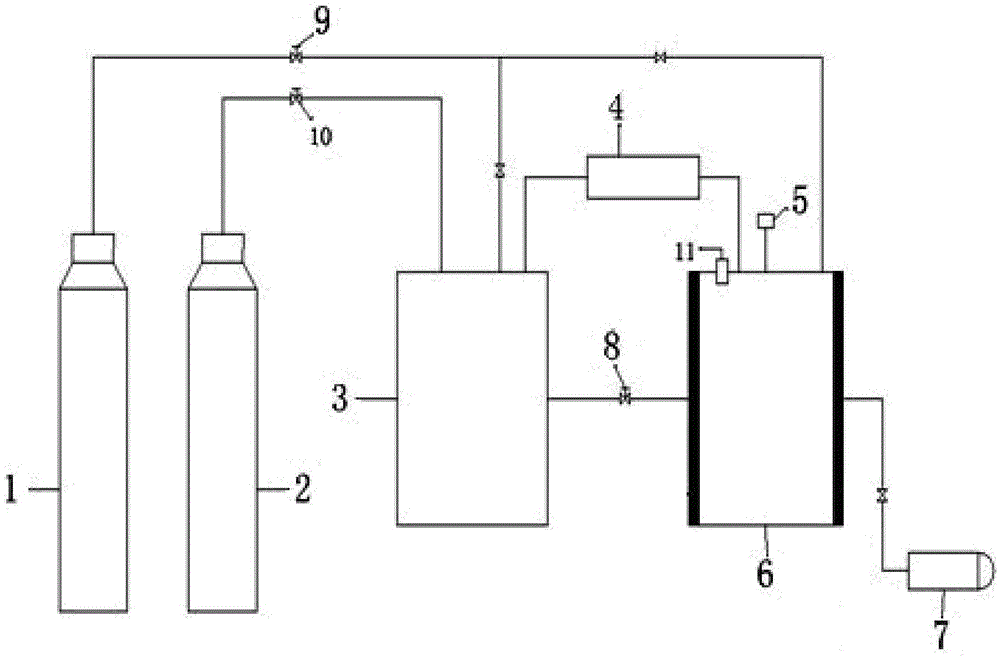

The invention discloses a spontaneous-combustion active ferrous sulfide gaseous phase passivation device and method. The device comprises a passivation tower, a vacuum pump, a nitrogen storage tank and an oxygen storage tank; the passivation tower is a container structure body, a feeding opening communicated with the interior of the passivation tower, an emptying valve, a nitrogen connector and a gas measurement connector are arranged in the top end of the passivation tower, and an exhaust opening and a mixed gas connector are formed in the middle; the vacuum pump is connected with the exhaust opening in the middle of the passivation tower through a pipeline with an electric control valve; the nitrogen storage tank is connected with the nitrogen connector of the passivation tower through a pipeline with an electric control valve and a nitrogen gas flowmeter and communicated with a buffer tank through a branch pipeline with an electric control valve; the oxygen storage tank is communicated with the buffer tank through a pipeline with an oxygen gas flowmeter; and the gas measurement connector of the passivation tower is connected to the buffer tank through a pipeline with a gas concentration analyzer in a looping manner; and the mixed gas connector of the passivation tower is communicated with the buffer tank through a pipeline with a mixed gas flowmeter. According to the device, effective gaseous phase passivation can be carried out on spontaneous-combustion active ferrous sulfide with low cost.

Description

technical field [0001] The invention relates to the field of treatment for suppressing spontaneous combustion active ferrous sulfide, in particular to a gas phase passivation device and method for spontaneous combustion active ferrous sulfide. Background technique [0002] Spontaneous combustion of ferrous sulfide in oil and gas storage tanks and oil refining units is common, and fires and explosions caused by this occur from time to time. During the maintenance process of the device, the ferrous sulfide dirt inside the equipment will be oxidized and release heat soon after contacting with the air. The reaction intensifies and burns, and then causes fires, explosions and other accidents inside oil and gas storage tanks and production facilities, often causing casualties, economic losses, environmental pollution and energy waste. [0003] Based on the fact that ferrous sulfide spontaneous combustion brings great harm, there are currently many methods to suppress the occurren...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23C8/12

CPCC23C8/12

Inventor 高建村朱佳华满孝梅任绍梅孟倩倩

Owner BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com