Flow valve

A technology of flow valve and needle valve, applied in the field of flow valve, can solve the problems of poor sealing performance of the discharge nozzle, complex structure and water overflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

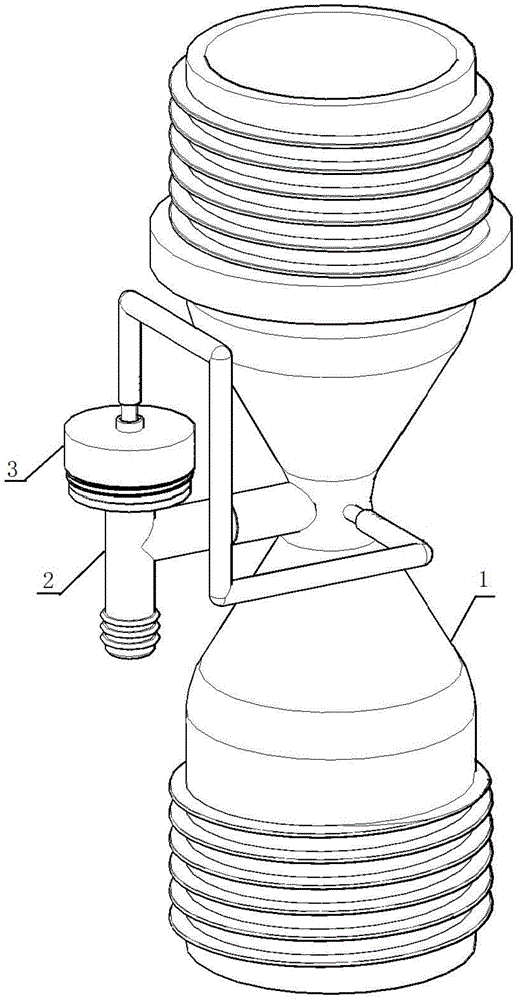

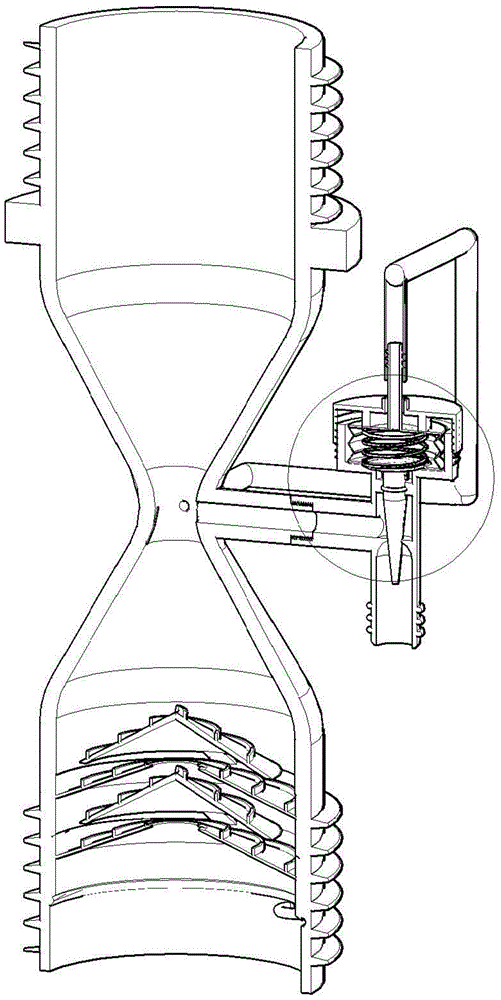

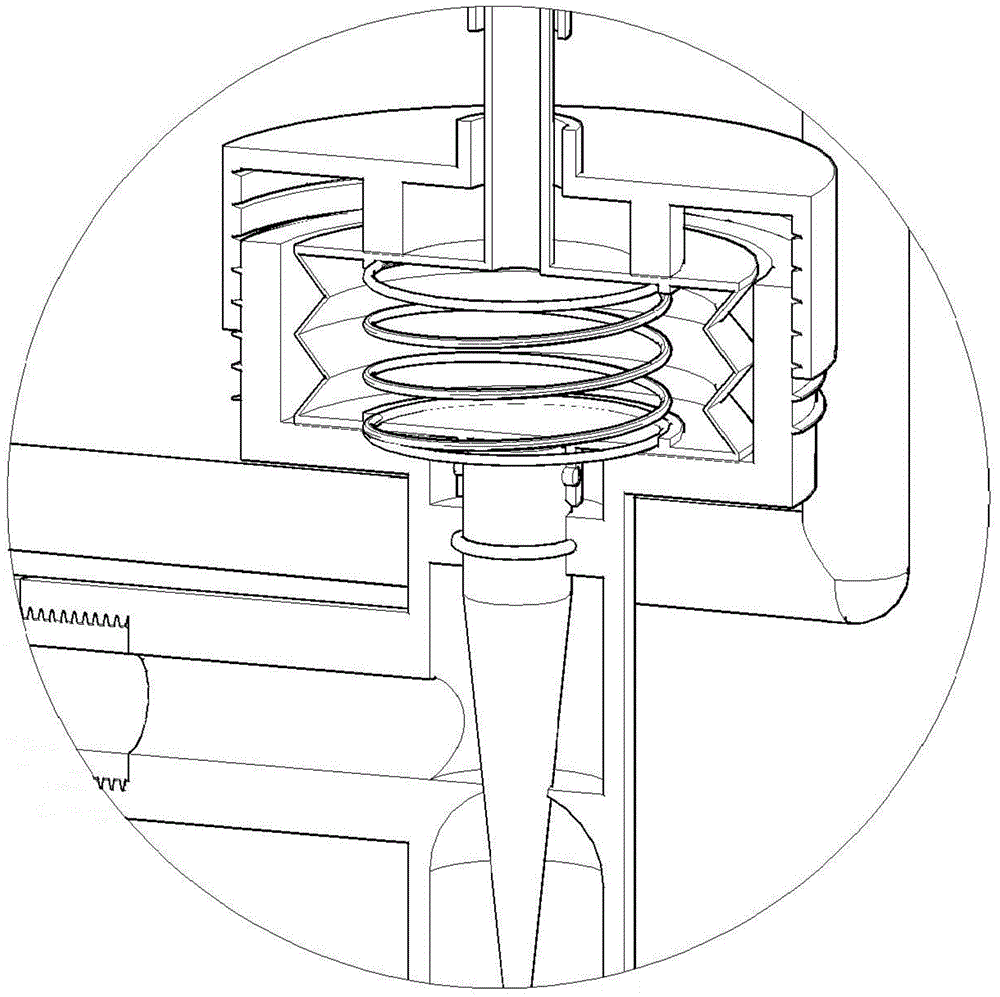

[0026] Such as figure 1 and image 3 As shown, a flow valve is used on a jet mixer with a Venturi structure, and is used to add an appropriate amount of detergent according to the pressure and flow of water in the jet mixer to form a suitable concentration in the jet mixer. The laundry liquid is injected into the washing tub; the inlet of the jet mixer is connected to the water inlet pipe, and the outlet is connected to the washing tub of the washing machine. When the washing machine is in the water inlet stage, negative pressure will be generated on the inner wall of the narrow part of the jet mixer. The size of the negative pressure depends on the pressure and flow of water. The negative pressure generated in the flow valve is transmitted to the flow valve connected to it, and a corresponding negative pressure is generated in the flow valve, so that the flow valve can be opened, detergent can be inhaled, and the inhaled detergent and water can be mixed to form laundry liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com