Natural gas hydraulic compression cylinder

A technology of natural gas liquid and compression cylinder, which is applied in the direction of liquid variable-capacity machinery, variable-capacity pump components, piston pumps, etc., which can solve the problems of increased natural gas loss, oil molecule mixing, and temperature rise, and achieve volume increase, The effect of increasing the amount of natural gas and lengthening the compression stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

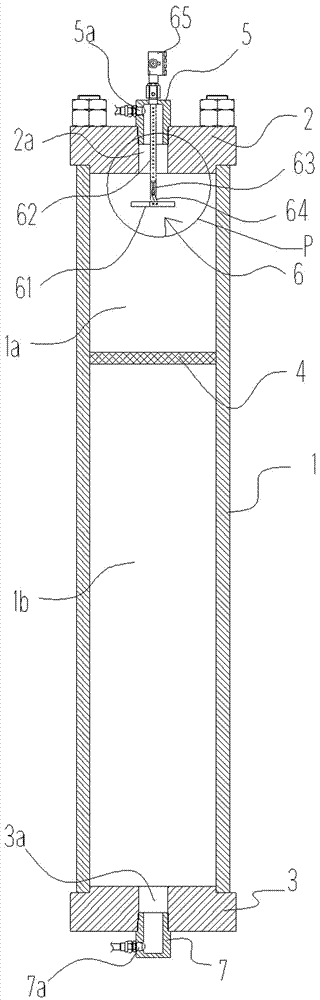

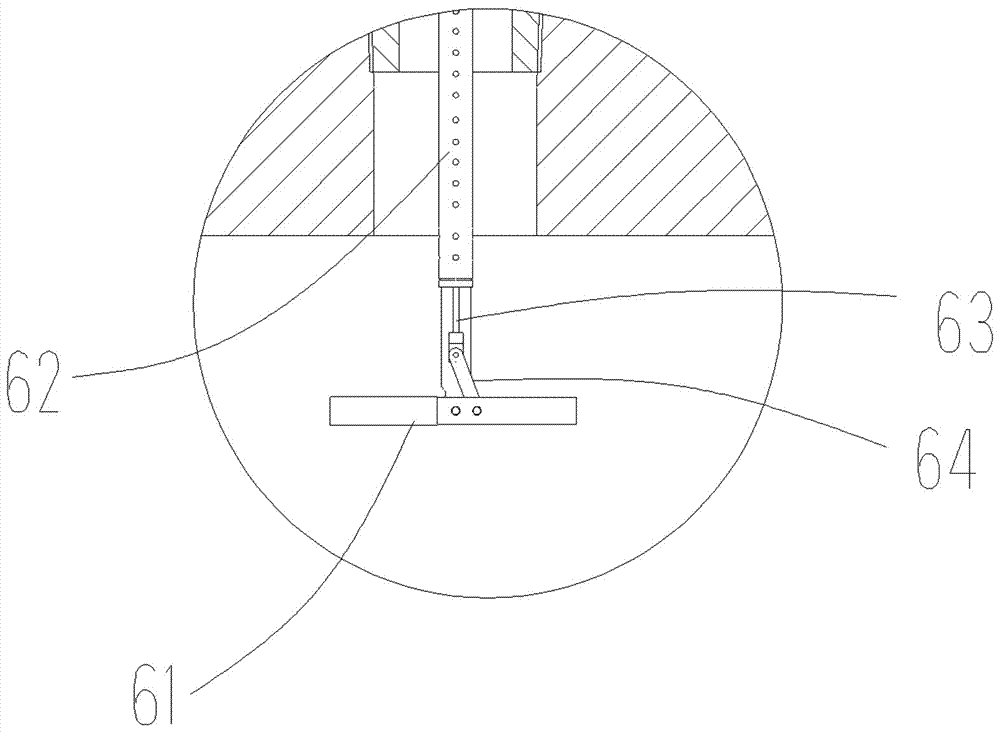

[0019] see figure 1 and figure 2 , an embodiment of the natural gas hydraulic compression cylinder of the present invention. The natural gas hydraulic compression cylinder includes a compression cylinder shell, the upper end of which is provided with a gas inlet and outlet 2a, and the lower end is provided with a liquid inlet and outlet 3a. The inner cavity of the compression cylinder housing is slidably matched with a movable partition 4 that moves up and down to isolate the gas medium and the liquid medium. It is divided into a gas compression chamber 1a and a liquid expansion chamber 1b, and the volumes of the gas compression chamber 1a and the liquid expansion chamber 1b change relative to each other as the movable partition 4 moves up and down. The movable dividing plate 4 that slide fits in the inner chamber of the compression cylinder housing adopts a polymer material plate, and the effect of the polymer material plate being a Teflon material plate is good, and of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com