Construction method for jacking structure of pipe jacking work well

A construction method and technology for working wells, which are applied in the directions of pipeline laying and maintenance, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of no limit device, poor waterproof effect, large friction between pipes and rails, etc. The effect of good water effect, reduced friction and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In this embodiment, the steel structure welding process, the bolt connection construction process, the shaft wall formwork setting process, and the concrete pouring construction process will not be repeated in this embodiment, and the embodiments related to the structure of the present invention will be focused on.

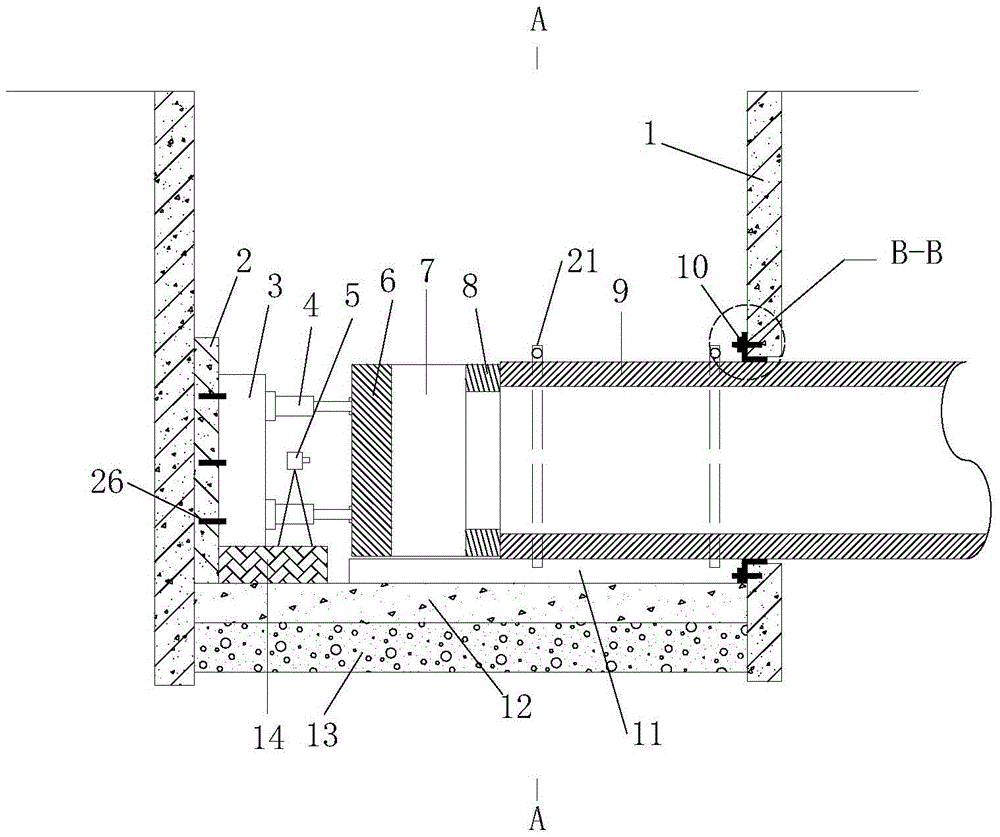

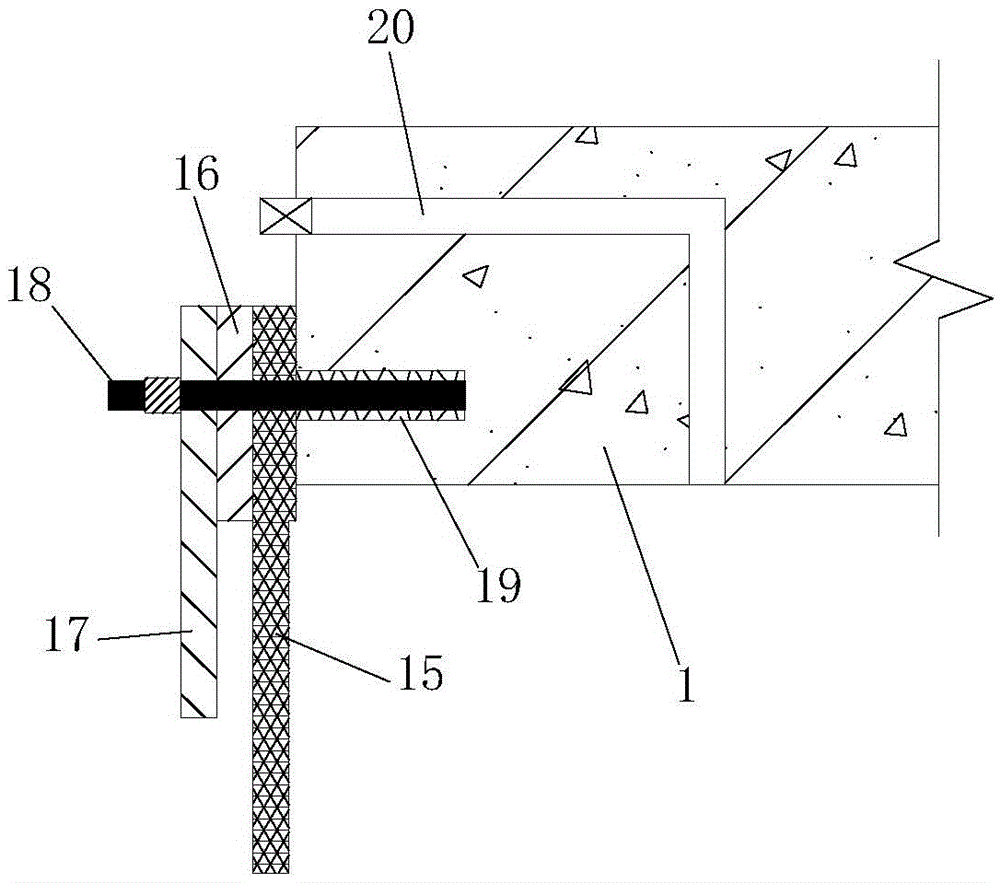

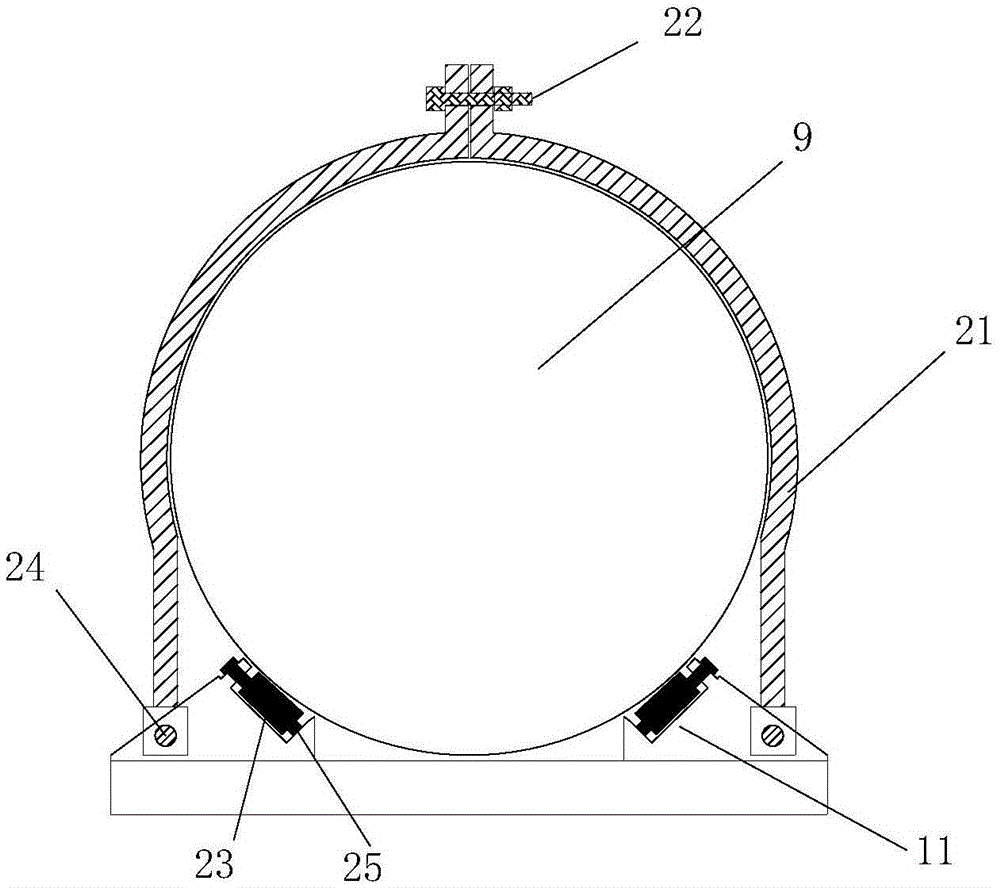

[0025] figure 1 It is a schematic diagram of the pipe jacking working well jacking structure of the present invention. refer to figure 1 As shown, the jacking structure of the pipe jacking well mainly includes: jack 4, measuring system 5, horizontal jacking iron 6, parallel jacking iron 7, ring jacking iron 8, pipe joint 9, hole water stop system 10, rail 11, guide wheel 23, hoop 21.

[0026] Before the jacking structure of the pipe-jacking working shaft is erected, a layer of sand and gravel cushion 13 is first laid at the bottom of the working well, a layer of concrete cushion is poured on the sand and gravel cushion, and the backseat wall 2 and Base14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com