A Method of Improving the Reliability of Tundish Baking Flame Detector

A flame detector and reliability technology, which is applied in the field of improving the reliability of a middle-package baking flame detector, can solve the problems of coking of the flame detector lens, unreasonable installation position of the flame detector, and malfunction, etc., so as to improve the reliability. , the effect of prolonging the service life and reducing the cost of spare parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

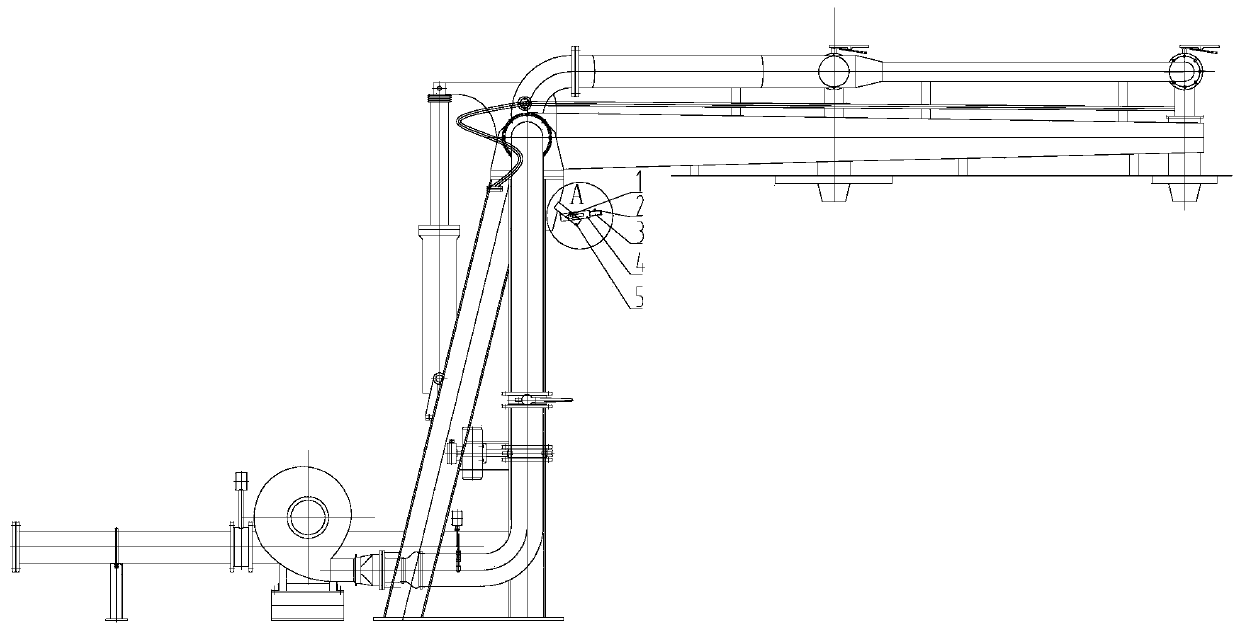

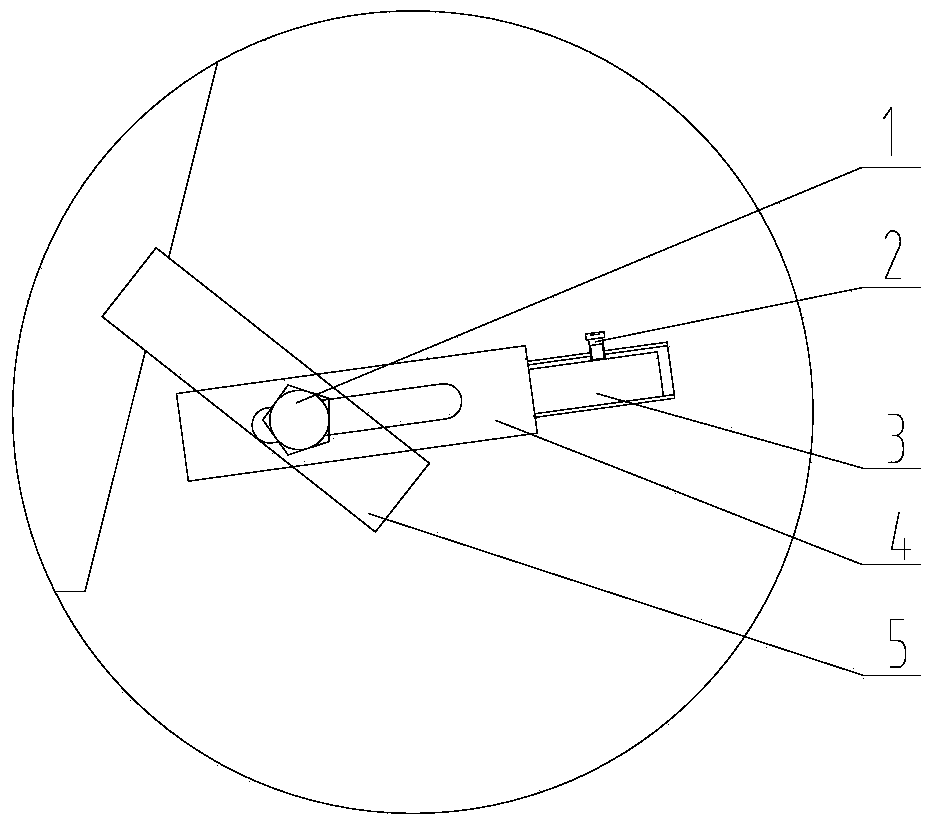

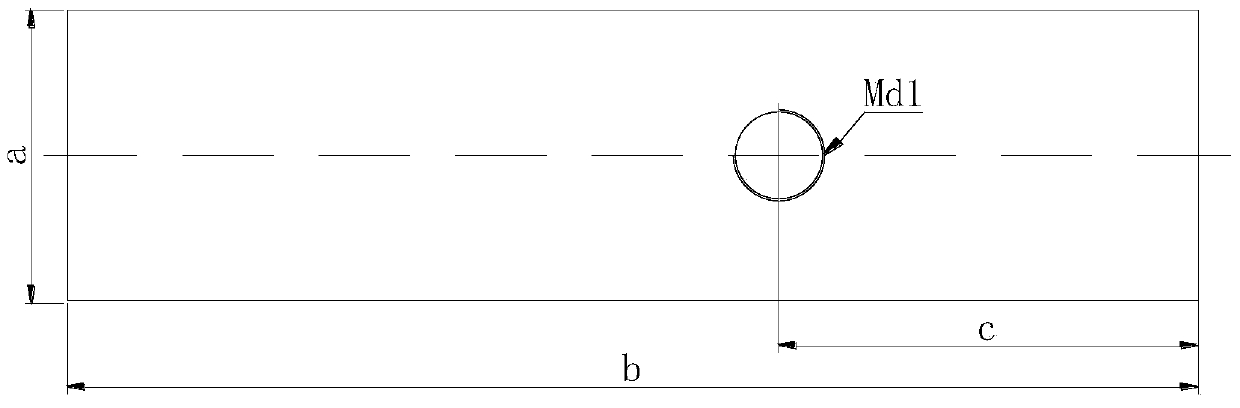

[0019] 1. Disassemble the flame detector 3 that was originally designed to be installed directly above the burner near the rocker arm rotation shaft, and seal the original design flame detector 3 storage device. Make the flame detector position adjustment mechanism fixing block 5, the material is Q235 steel, the dimensions are: a=50mm, b=200mm, c=75mm, d1=16mm, m1=5mm, and the flame detector adjustment mechanism fixing block 5 Welded on the outside of the rocker arm rotation shaft. Make flame detector position adjustment mechanism 4, material is Q235 steel, size is respectively, e=50mm, f=280mm, g=200mm, h1=50mm, h2=50mm, h3=20mm, k=40mm, d2=8mm, d3=32mm, d4=28mm, m2=5mm.

[0020] 2. Install the flame detector 3 into the seamless steel pipe of the flame detector position adjustment mechanism 4, and fix the flame detector 3 in the seamless steel pipe with the M8 flame detector locking screw 2, so as to isolate the high temperature radiation role. Fix the flame detector posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com