Novel frequency converter

A frequency converter and frequency converter control technology, applied in the field of frequency converters, can solve problems such as high temperature, unsatisfactory self-cooling and heat dissipation methods, and poor heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

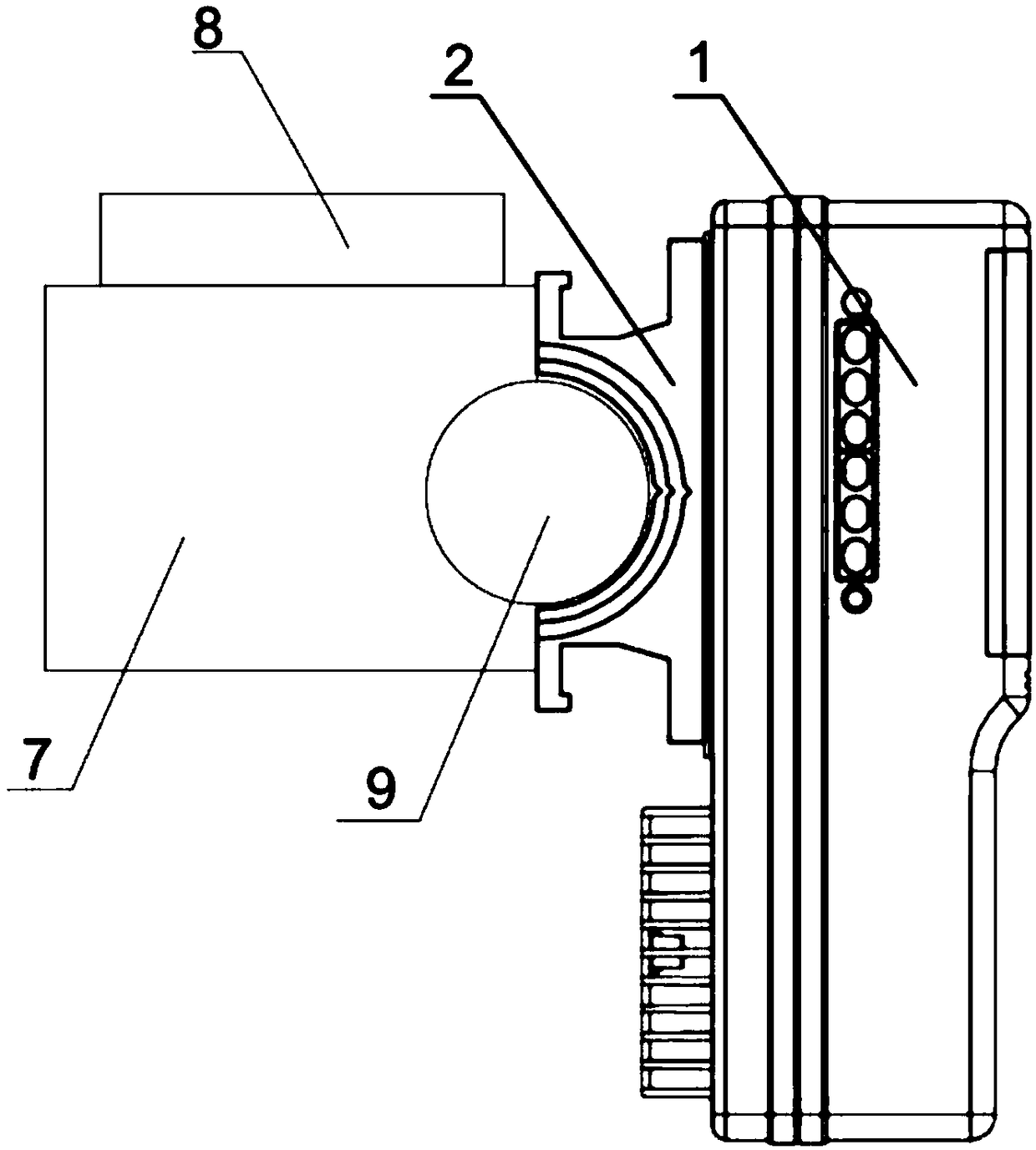

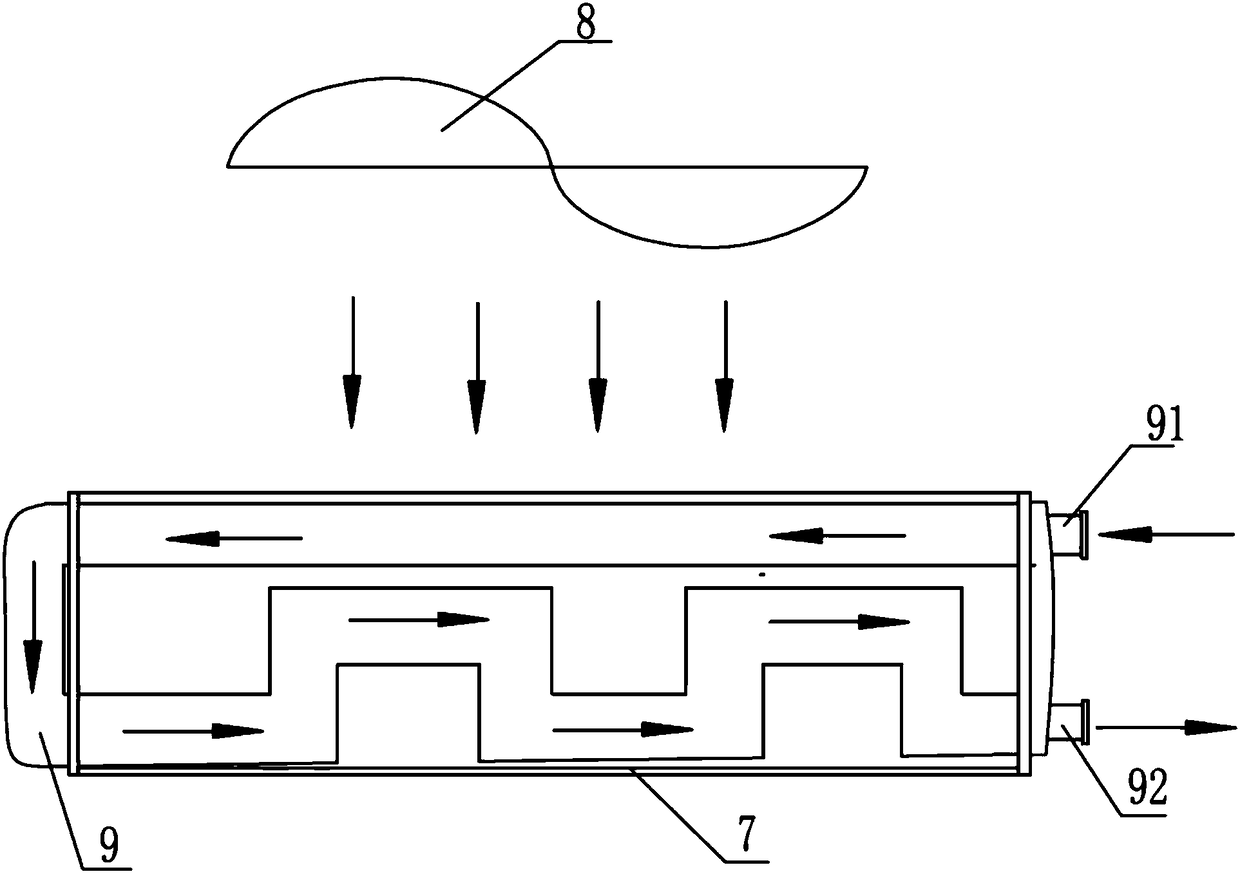

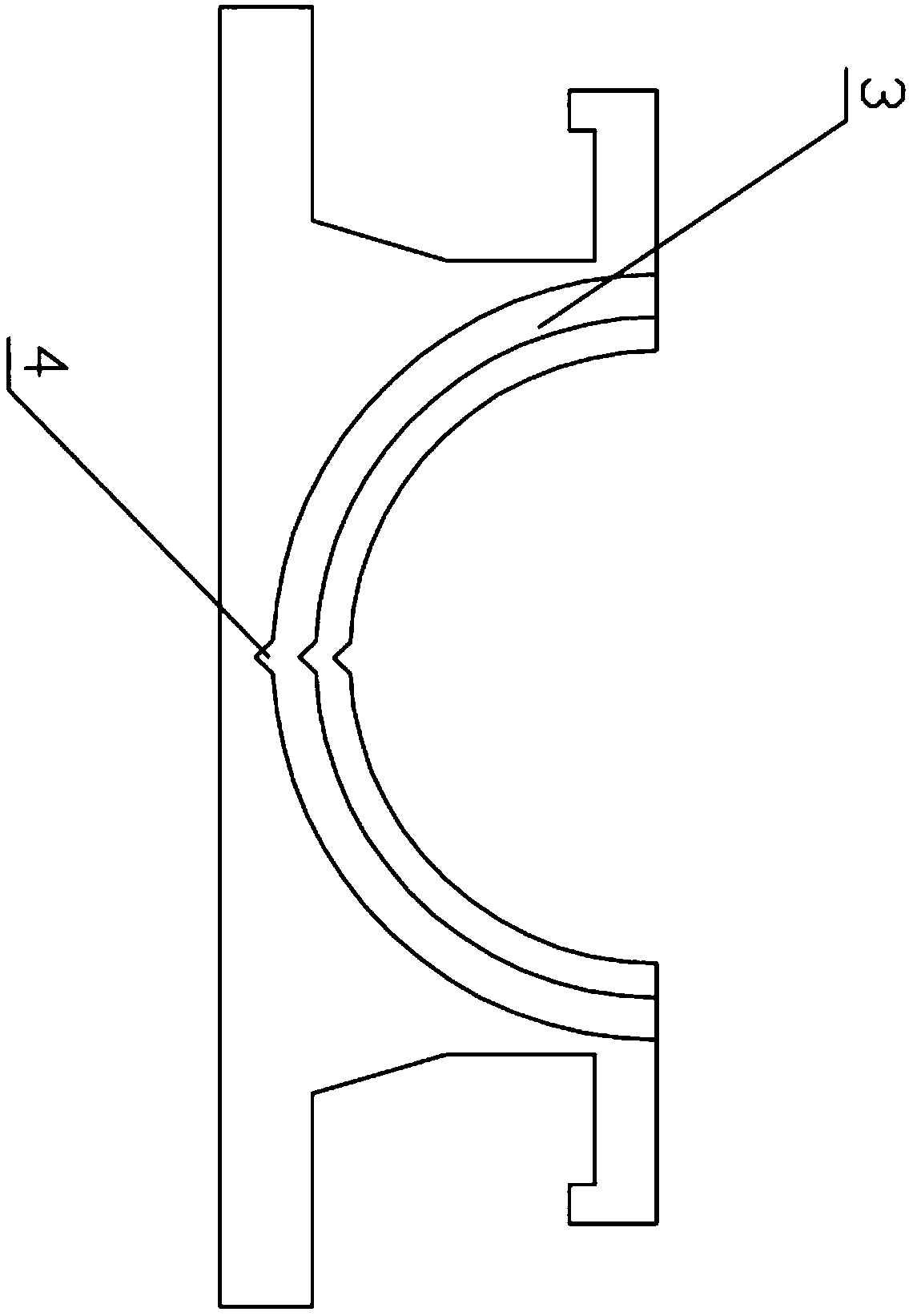

[0024] Such as Figure 1-5 As shown, the present invention provides a new type of frequency converter, including a frequency converter housing 1, an opening 5 is arranged on the rear surface of the frequency converter housing 1, and a frequency converter control board is arranged in the frequency converter housing. Described opening 5 place is provided with described heat dissipation device, and described heat dissipation device comprises: heat dissipation seat 2, air cooler 7 and the blower fan 8 that is arranged on the top of air cooler 7; Said air cooler 7 is provided with liquid pipe 9, and described liquid pipe 9 A liquid inlet 91 and a liquid outlet 92 are provided; specifically, the heat dissipation seat 2 is arranged at the opening, and the heat dissipation seat 2 is provided with a fixing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com