A Ring Accelerated Loading Experimental System

An accelerated loading and experimental system technology, which is applied in the field of loop accelerated loading experimental systems, can solve problems such as low speed, high energy consumption, and actual inconsistency, and achieve the effects of increasing experimental speed, low energy consumption, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] as attached figure 1 As shown, a loop accelerated loading test system of the present invention includes a loading car I and a ring test track II used with the loading car I.

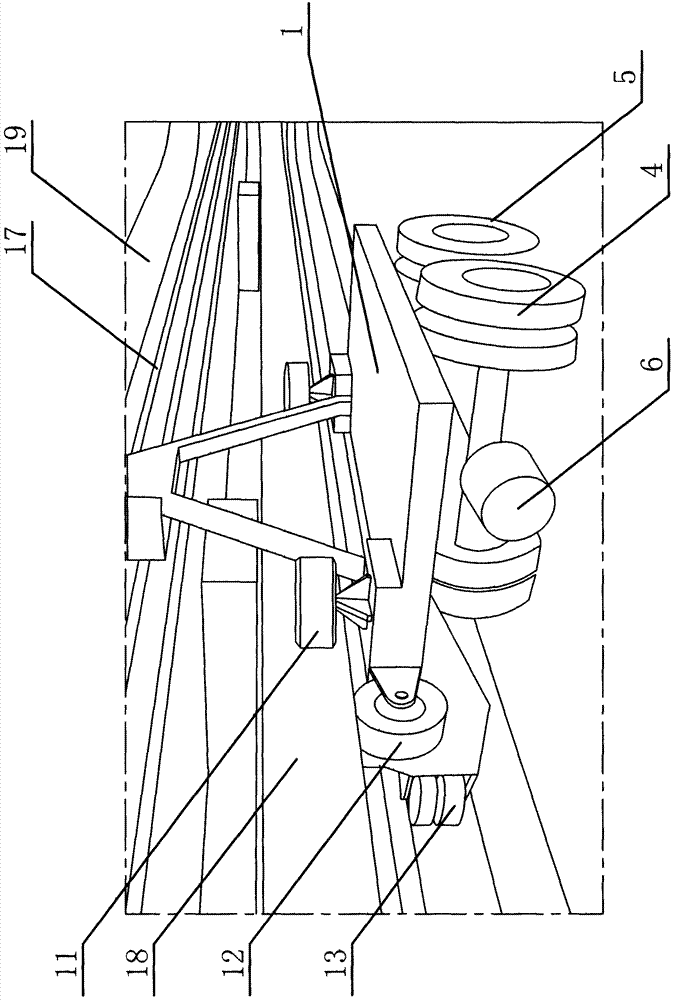

[0032] as attached Figure 2-4 As shown, the loading vehicle 1 includes an upper frame 1, a guide post 2, a guide sleeve 3, a driving wheel 4, a driven wheel 5, a motor 6, a reducer 7, a transmission shaft 8, a traverse screw 9, and a lower frame 10. Guide wheel 11, balance wheel 12, lateral support wheel 13, third rail receiver 14, the bottom of the upper frame 1 is horizontally provided with guide posts 2 and traversing screw 9 parallel to each other, and guide posts 2 are provided with There is a guide sleeve 3, the lower frame 10 is arranged on the guide sleeve 3, and the lower frame 10 is provided with a screw nut, a driving wheel 4 and a power mechanism connected with the driving wheel 4, the wheel shaft of the driving wheel 4 is connected to the guide Column 2 is parallel.

[0033] The t...

Embodiment 2

[0039] as attached figure 1 As shown, a loop accelerated loading test system of the present invention includes a loading car I and a ring test track II used with the loading car I.

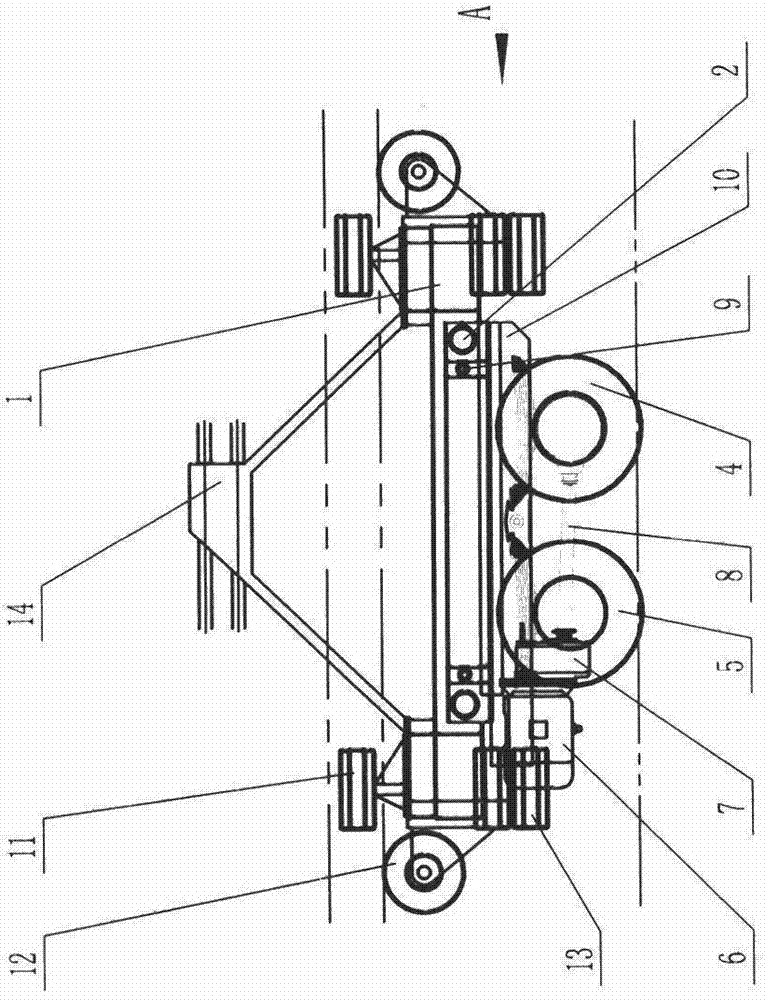

[0040] as attached Figure 5 As shown, the loading vehicle 1 includes an upper frame 1, a guide column 2, a guide sleeve 3, a driving wheel 4, a motor 6, a reducer 7, a transmission shaft 8, a traverse screw 9, a lower frame 10, and a guide wheel 11. The balance wheel 12, the lateral support wheel 13, the third rail receiver 14, the bottom of the upper frame 1 is horizontally provided with a guide post 2 and a traverse screw 9, and the guide post 2 is provided with a guide sleeve 3, get off The frame 10 is arranged on the guide sleeve 3 . The lower frame 10 is provided with a lead screw nut, a drive wheel 4, a motor 6, a speed reducer 7, and a transmission shaft 8, the motor 6 is connected with the transmission shaft 8 through the speed reducer 7, and the transmission shaft 8 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com