Design method for fast sampler

A design method and sampler technology, applied in the field of boilers, can solve problems such as user experience needs to be improved, troubles, etc., and achieve the effect of improving user experience, high efficiency, and good user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

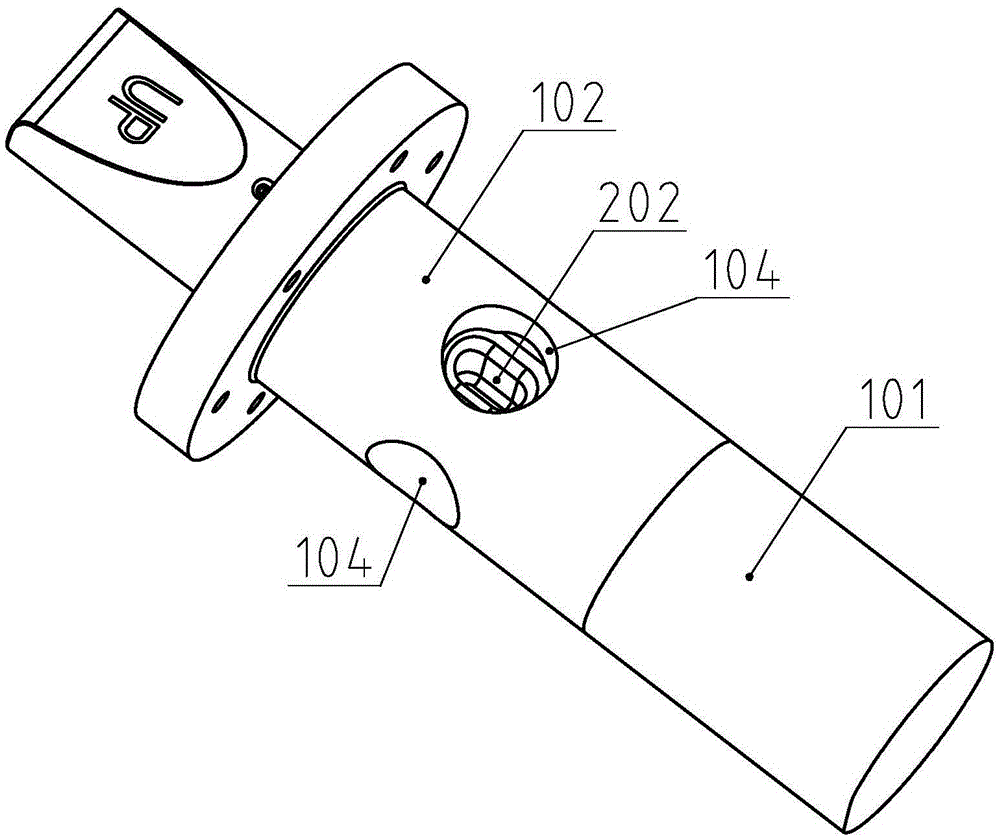

[0051] In order to distinguish the head and the tail of the parts, the part close to the handle 204 is called the tail, and the part far away from the handle 204 is called the head.

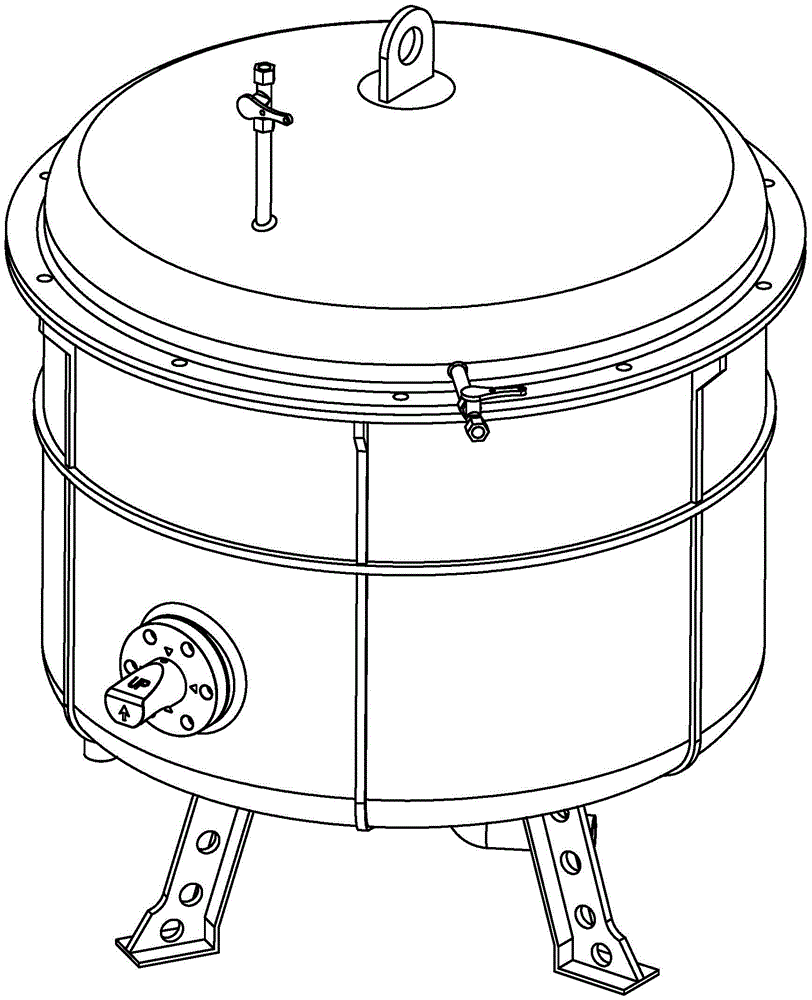

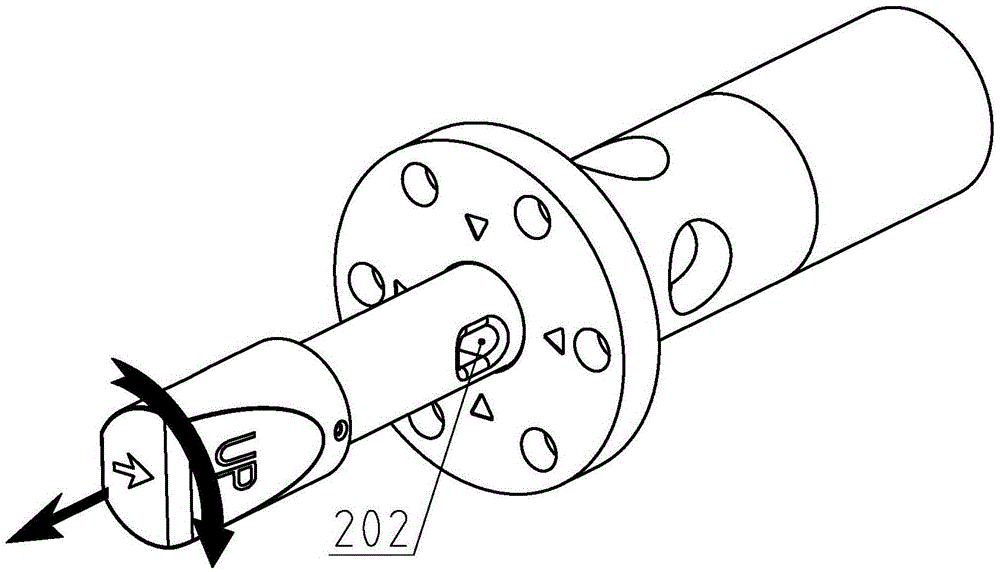

[0052] like figure 1 As shown, a sampler is installed near the bottom of the side wall of the boiler, and the sampling rod 2 is in the insertion position. When it is necessary to sample the liquid in the boiler, the sampling rod 2 only needs to be pulled out, and the sampling hole on the sampling rod 2 is 202 is fully exposed, that is, the sampling rod 2 is in the pulled out position (see Figure 7 ), turn the sampling rod 2 (see image 3 and 8 ), that is, the liquid in the sampling hole 202 is poured into the container, and then the sampling rod 2 is rotated and pushed back to the insertion position. The sampling process only needs three actions, one pull, one turn and one push, which is convenient and fast, with less actions, short time and high sampling efficiency.

[0053] like figure 2...

Embodiment 2

[0079] like Figure 14-16 As shown, the limiter 3 is provided with two limit pins 301 and one extension spring 302, the extension spring 302 and the limit pin 301 are coaxially arranged, the two limit pins 301 are placed oppositely, and the extension spring 302 makes The shoulder end surface 303 of the limiting pin 301 cooperates with the outer cylindrical surface of the sampling rod 2 , and the shoulder cylindrical surface 304 of the limiting pin 301 cooperates with the stepped surface 111 of the base 102 . Such setting realizes the friendliness of assembly. First, turn the two mounting holes at the head end of the sampling rod 2 to a horizontal position, and then conveniently install the two limit pins 301 from the outer cylindrical surface of the sampling rod 2 into corresponding positions. Then one end of the extension spring 302 is hooked to the stop pin 301, and then the extension spring 302 is elongated by a certain amount and hooked to another stop pin 301. After assem...

Embodiment 3

[0081] like Figure 12 As shown, the number of the second through holes 104 of the base 102 in the first embodiment is set to 1, and the diameter of the second through holes 104 is larger than the diameter of the first through holes 103. A certain space is formed on both sides, and such a space serves as a flow area 111 , which facilitates the flow of the liquid in the second through hole 104 , thereby renewing the liquid around the sampling hole 202 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com