Movable concrete slump test bench

A slump and concrete technology, which is applied in the field of mobile concrete slump test benches, can solve the problems of lack of a movable platform, inconvenience, on-site environmental pollution, etc., and achieves easy cleaning and recycling, low manufacturing cost, structural Simple and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

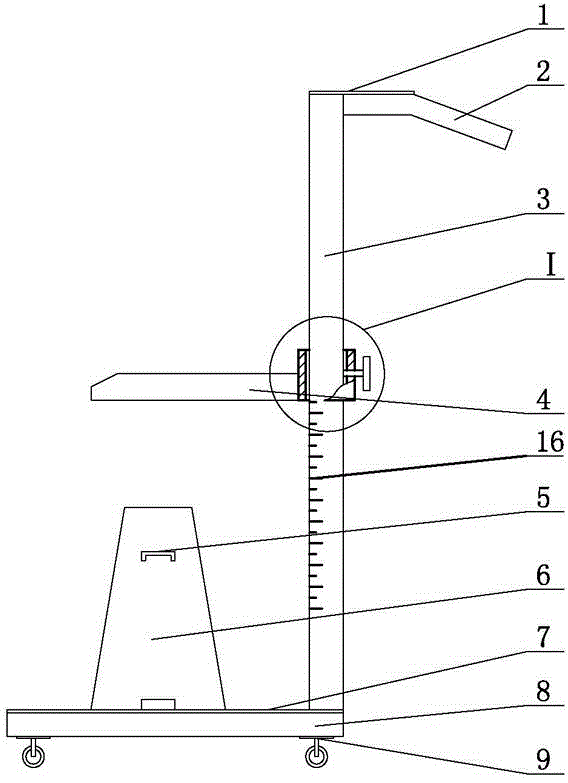

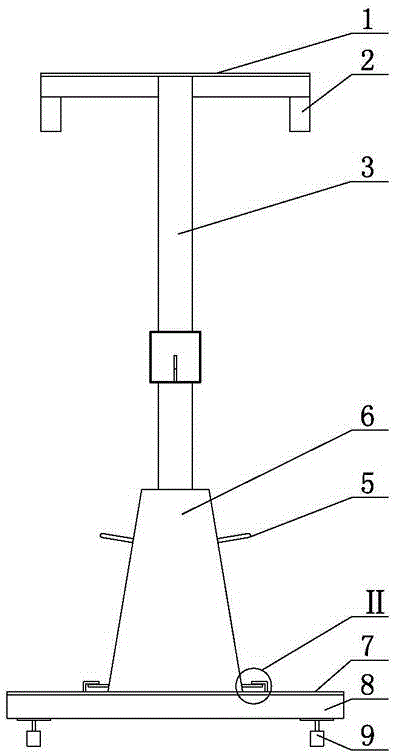

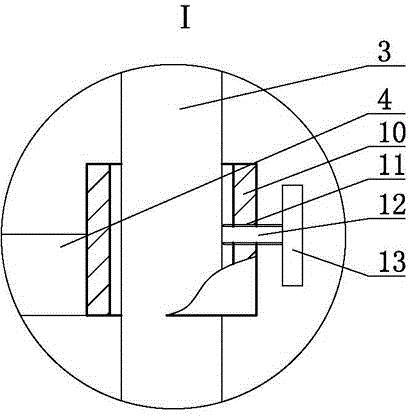

[0012] Mobile concrete slump test bench, such as figure 1 , figure 2 and image 3 As shown, including a base 8, several universal wheels 9 are arranged on the bottom of the base 8, a metal plate 7 is installed on the top of the base 8, a slump tester 6 is arranged on the metal plate 7, and a slump tester is located on the metal plate 7 6 A steel pipe fixing column 3 is arranged on one side, and the middle part of the steel pipe fixing column 3 is covered with a fixed pipe 10. One side of the fixed pipe 10 is installed with a height measuring plate 4, and the other side of the fixed pipe 10 is provided with a screw hole 11, and a wire is installed in the screw hole 11. Rod 12, second handle 13 is installed on one end of screw mandrel 12, and the side of steel pipe fixed post 3 is provided with scale 16. The upper end of the steel pipe fixing column 3 is connected to one end of the steel plate 1 , and the other end of the steel plate 1 is connected to the handrail 2 . The me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com