Insulator zero value comprehensive test device

A testing device and insulator technology, which is applied in the direction of measuring device, testing dielectric strength, measuring electricity, etc., can solve the problems of large safety risks, high labor intensity of operators, and easy occurrence of missed testing, and achieves good data repeatability and improved Test efficiency and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

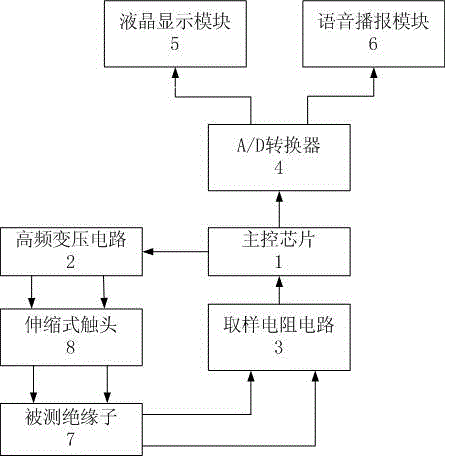

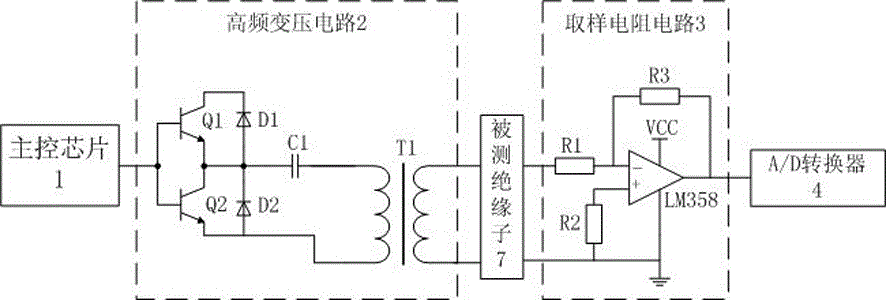

[0015] Attached below Figure 1~2 The present invention is further described.

[0016] refer to Figure 1~2 : The embodiment comprises an insulating shell, a main control chip 1 arranged in the insulating shell, a high frequency transformer circuit 2, a sampling resistance circuit 3, an A / D converter 4, a liquid crystal display module 5 and a voice broadcast module 6; the high voltage The output end of the frequency conversion circuit 2 is provided with telescopic contacts 8; At the input terminal of the tested insulator 7, the output terminal of the tested insulator 7 is connected to the input terminal of the sampling resistance circuit 3, and the output terminal of the sampling resistance circuit 3 is connected to the input terminal of the main control chip 1. The video and audio signal output terminal of the control chip 1 is connected to the liquid crystal display module 5 and the voice broadcast module 6 through the A / D converter 4; one side of the insulating shell is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com