A vacuum interrupter

A vacuum interrupter and guide sleeve technology, applied in high-voltage air circuit breakers, electrical components, electrical switches, etc., can solve the problems of decreased mechanical life of products, sprained bellows, broken bellows, etc., and achieves low cost and reliable welding. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

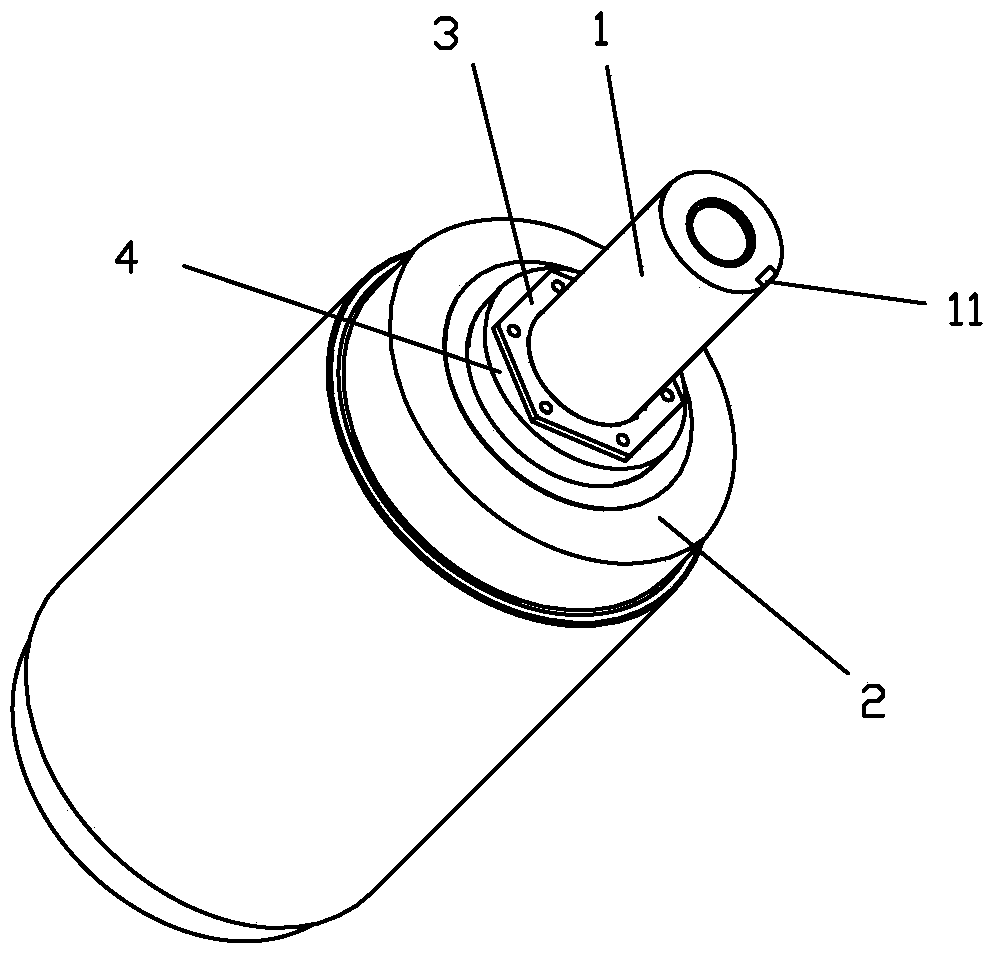

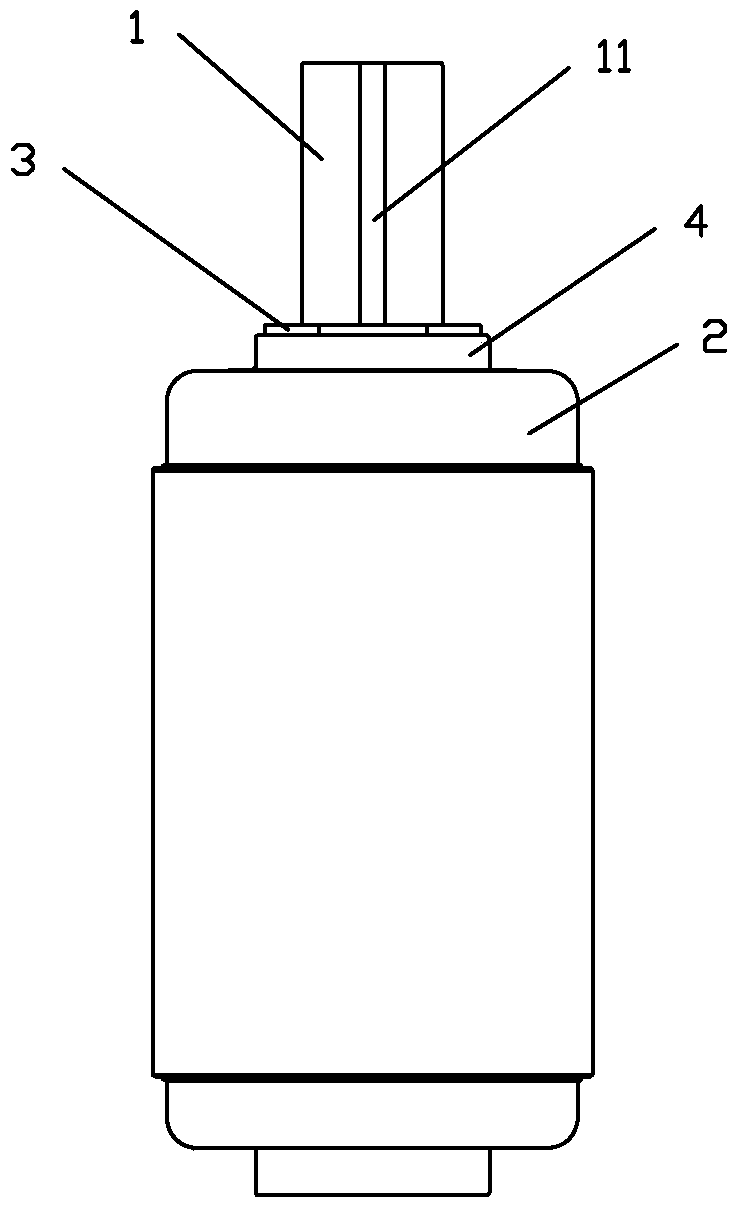

[0034] see Figure 1 to Figure 11 As shown, a vacuum interrupter of the present invention includes a movable conductive rod 1, a movable end sealing ring 2 adapted to the movable conductive rod, a guide sleeve 3 and a fixed ring 4, the guide sleeve 3 and the fixed ring 4 are composed of To the outside, it is sequentially socketed on the movable conductive rod 1, and the guide sleeve 3 is connected to the movable end sealing ring 2 through the fixed ring 4; the guide sleeve 3 and the fixed ring 4 are respectively provided with anti-rotation planes that can prevent mutual rotation, When the fixed ring 4 is socketed with the guide sleeve 3, the anti-rotation plane of the guide sleeve 3 cooperates with the anti-rotation plane of the fixed ring 4, so that the guide sleeve 3 and the fixed ring 4 cannot rotate mutually along the circumferential direction.

[0035] The guide sleeve 3 is provided with a boss 31 that protrudes along the axial direction, and at least one first anti-rotat...

Embodiment 2

[0043] see Figure 12 to Figure 13 As shown, a vacuum interrupter of the present invention differs from Embodiment 1 in that the peripheral shape of the cross-section of the boss 31 of the guide sleeve 3 is pentagonal, and the peripheral wall of the boss is provided with There are five first anti-rotation planes 32 corresponding to the pentagon, and the inner ring wall of the fixed ring 4 is provided with five second anti-rotation planes adapted to the first anti-rotation planes 32 of the guide sleeve 41. When the fixed ring 4 is socketed with the guide sleeve 3, the first anti-rotation planes 32 of the guide sleeve 3 are respectively matched with the corresponding second anti-rotation planes 41 of the fixed ring, so that the guide sleeve 3 and the fixed ring 4 Cannot rotate mutually along the circumferential direction.

Embodiment 3

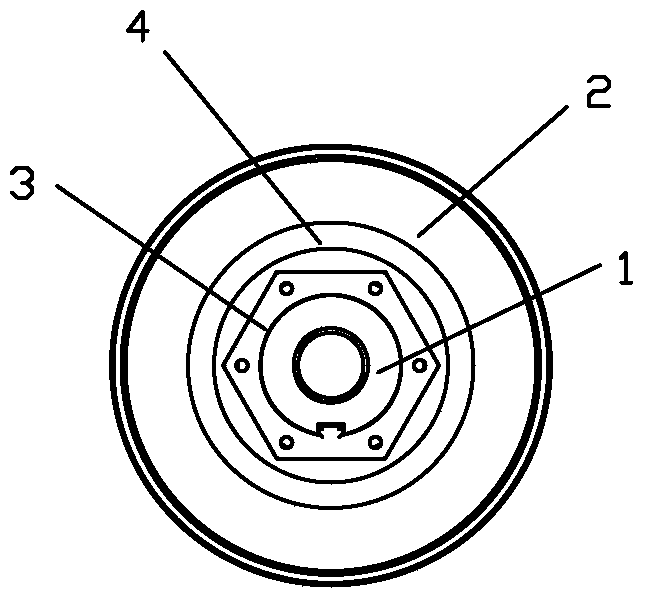

[0045] see Figure 14 to Figure 15 As shown, a vacuum interrupter of the present invention differs from Embodiment 1 in that the peripheral shape of the cross-section of the boss 31 of the guide sleeve 3 is octagonal, and the peripheral wall of the boss is provided with There are eight first anti-rotation planes 32 corresponding to the octagon, and the inner ring wall of the fixed ring 4 is provided with eight second anti-rotation planes compatible with the first anti-rotation planes 32 of the guide sleeve 41. When the fixed ring 4 is socketed with the guide sleeve 3, the first anti-rotation planes 32 of the guide sleeve 3 are respectively matched with the corresponding second anti-rotation planes 41 of the fixed ring, so that the guide sleeve 3 and the fixed ring 4 Cannot rotate mutually along the circumferential direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com