Laminated sealing sheet

一种玻璃密封、包层的技术,应用在层压密封板领域,能够解决薄膜密封受损、划伤或剥离、增加成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

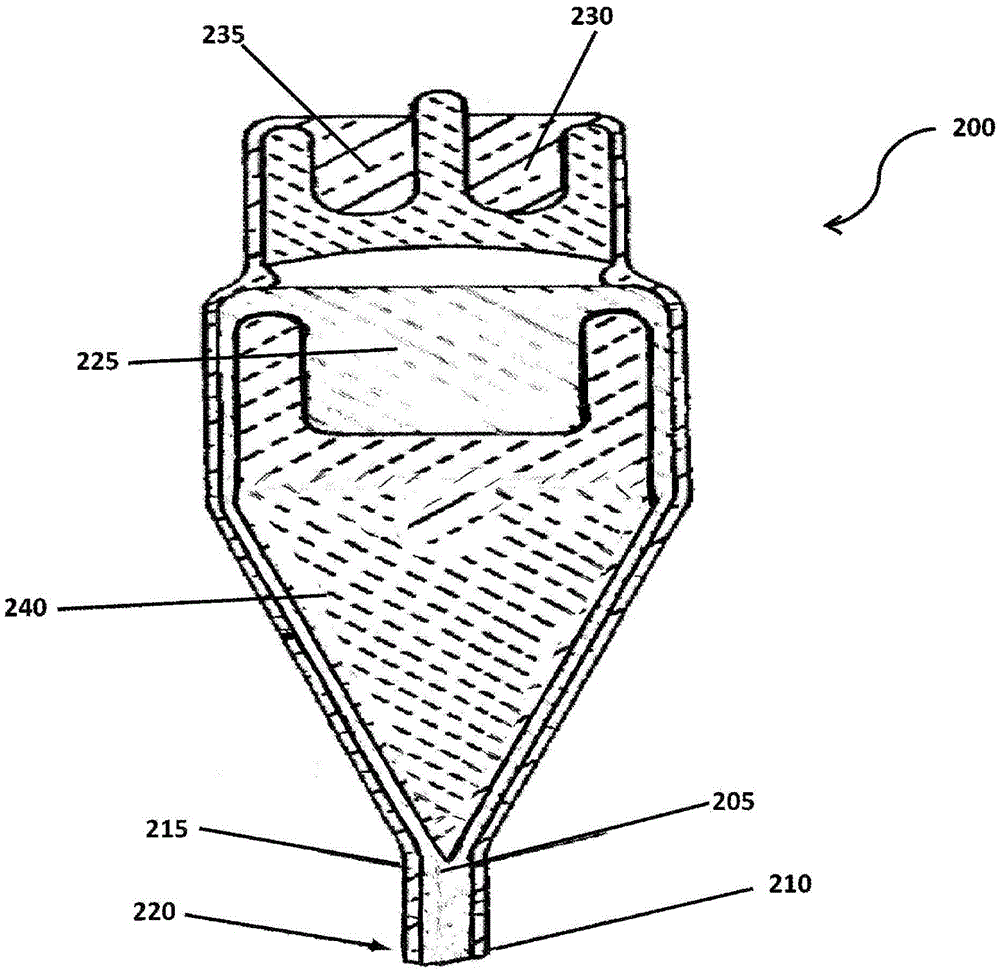

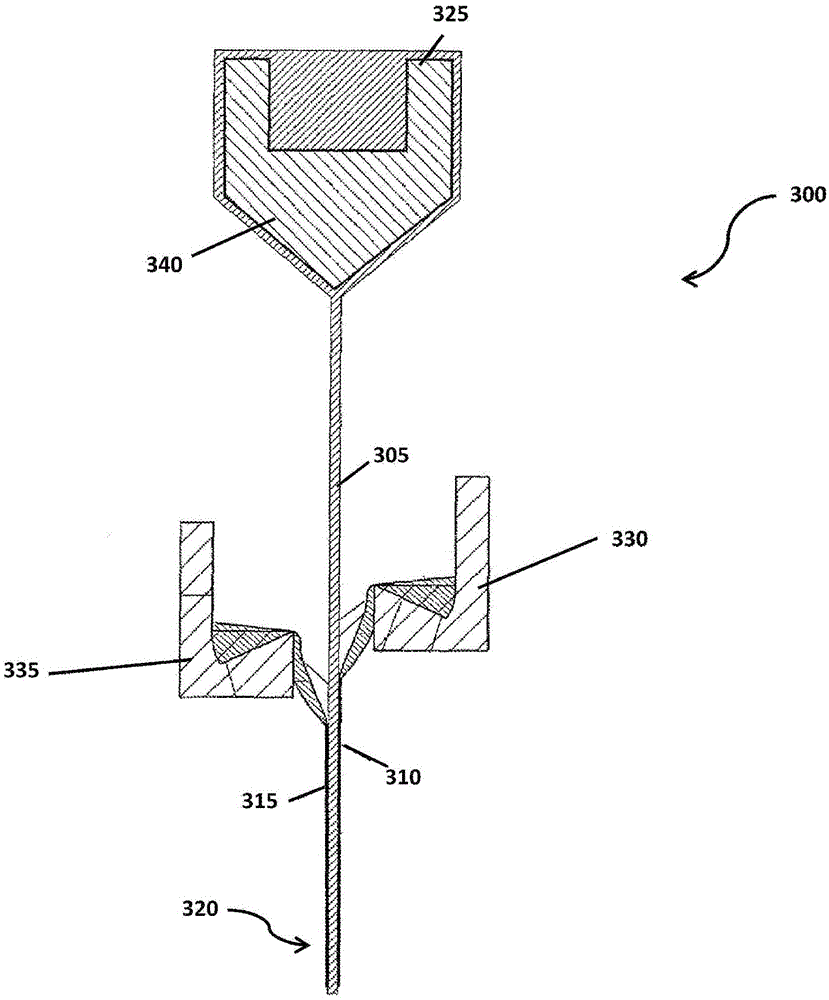

[0021] Reference is now made in detail to embodiments of glass sealing panels, methods of making glass sealing panels, glass packages, and methods for making glass packages, examples of which are illustrated in the accompanying drawings. A glass sealing plate for sealing an OLED and a glass package comprising a glass sealing plate and an OLED are set forth in greater detail in some embodiments. However, it should be noted that this is merely an exemplary embodiment of the invention disclosed herein. The present invention is applicable to other technologies that are susceptible to problems similar to those described above. For example, embodiments for sealing electronic and photonic devices and structures are clearly within the scope of the present invention. These devices and structures may include, but are not limited to, integrated circuits and semiconductor structures. Furthermore, the exemplary embodiments are applicable to other types of optical devices besides OLED dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| coefficient of linear thermal expansion | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com