Reconstituted milk yogurt additive composition, application thereof, reconstituted milk yogurt, and preparation method

A lactic yogurt and composition technology, which is applied in applications, dairy products, milk preparations, etc., can solve the problems of reducing the liking of reconstituted lactic yogurt, and the flavor cannot be improved by adjusting the raw material index, so as to increase the nutritional value and taste refreshing Smooth and delicate, the effect of ensuring the state of the tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

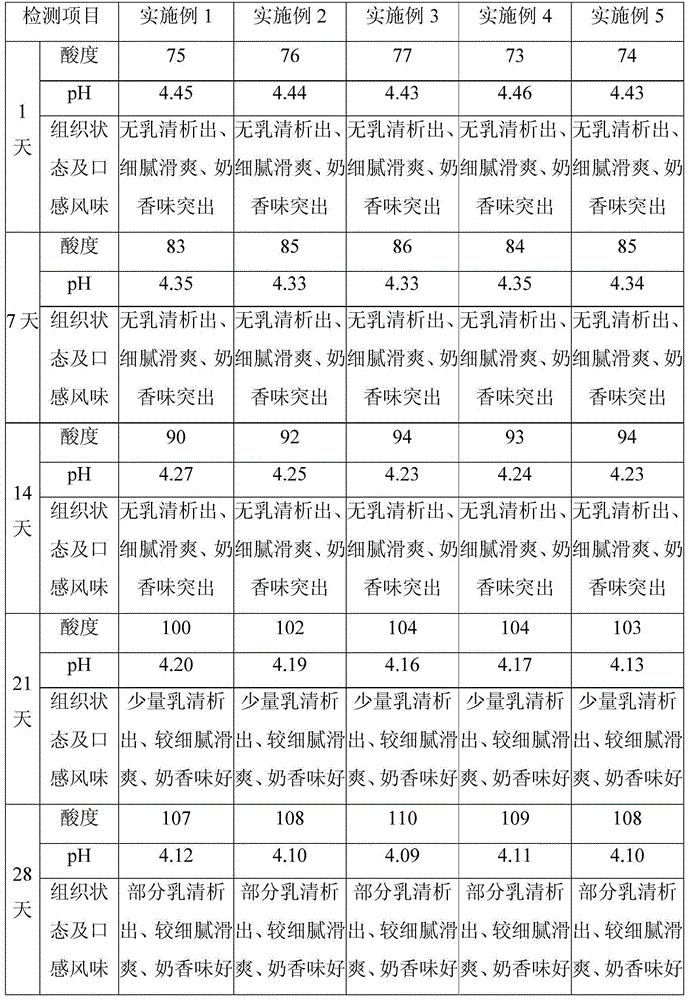

Examples

Embodiment 1

[0061] 1. Raw material formula (measured in 1000g):

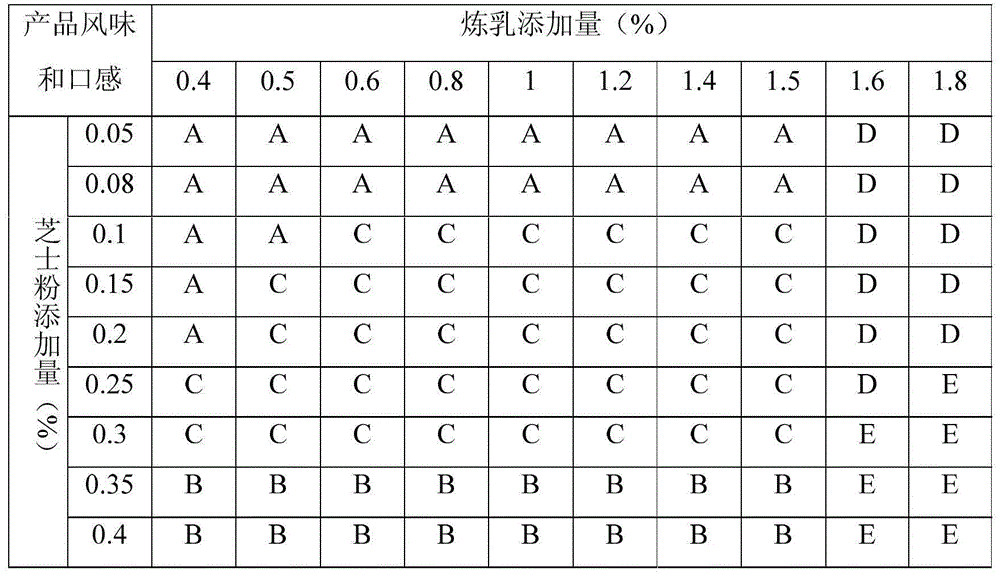

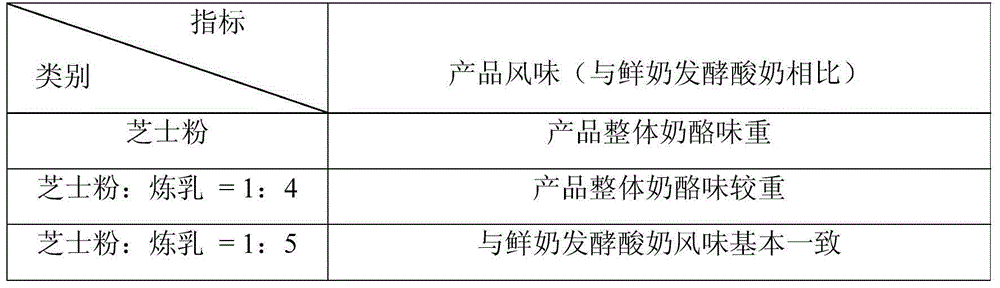

[0062] Reconstituted milk: 925.91g; White sugar: 60g; Cheese powder: 2g; Condensed milk: 14g; :2).

[0063] 2. Production method:

[0064] 1. Add skimmed milk powder and cream to the ingredients water, and heat to 45°C to dissolve for 30 minutes;

[0065] 2. Hydrate at a constant temperature of 45°C for 30 minutes;

[0066] 3. Mix the ingredients of the yogurt described in the present invention evenly at 60°C for 32 minutes;

[0067] 4. The mixed material is degassed and homogenized at 60°C and 20MP pressure;

[0068] 5. The homogenized mixture is sterilized at 110°C for 10 minutes;

[0069] 6. Cool to 43°C, add appropriate amount of fermentation strains;

[0070] 7. Ferment at 43°C until the acidity reaches 76°T, stop the fermentation;

[0071] 8. Put the yogurt into the yogurt buffer tank and prepare for filling;

[0072] 9. Refrigerate at 4°C and cook before leaving the factory.

Embodiment 2

[0074] 1. Raw material formula (measured in 1000g):

[0075] Reconstituted milk: 977.52g; Cheese powder: 3g; Condensed milk: 15g; Milk protein powder: 4g; Pectin: 0.4g; :1.5).

[0076] 2. Production method:

[0077] 1. Add the whole milk powder into the ingredient water and heat to 40°C to dissolve for 35 minutes;

[0078] 2. Hydrate at a constant temperature of 40°C for 35 minutes;

[0079] 3. Mix the ingredients of the yogurt described in the present invention evenly at 65°C for 30 minutes;

[0080] 4. The mixed material is degassed and homogenized at 65°C and 18MP pressure;

[0081] 5. The homogenized mixed material is sterilized at 95°C for 300s;

[0082] 6. Cool to 42°C, add appropriate amount of fermentation strains;

[0083] 7. Stop fermentation when the acidity reaches 74°T at 42°C;

[0084] 8. Put the yogurt into the yogurt buffer tank and prepare for filling;

[0085] 9. Refrigerate at 6°C and cook before leaving the factory.

Embodiment 3

[0087] 1. Raw material formula (measured in 1000g):

[0088] Reconstituted milk: 901.9g; White sugar: 90g; Cheese powder: 1g; Condensed milk: 7g; :2).

[0089] 2. Production method:

[0090] 1. Add the whole milk powder into the ingredient water and heat to 50°C to dissolve for 25 minutes;

[0091] 2. Hydrate at a constant temperature of 50°C for 25 minutes;

[0092] 3. Mix the ingredients of the yogurt described in the present invention evenly at 55°C for 35 minutes;

[0093] 4. The mixed material is degassed and homogenized at 60°C and 20MP pressure;

[0094] 5. The homogenized mixed material is sterilized at 121°C for 4s;

[0095] 6. Cool to 42°C, add appropriate amount of fermentation strains;

[0096] 7. Ferment at 42°C until the acidity reaches 78°T, stop the fermentation;

[0097] 8. Put the yogurt into the yogurt buffer tank and prepare for filling;

[0098] 9. Refrigerate at 6°C and cook before leaving the factory.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com