Magnetic attracting device for iron scraps in long-deep hole

A suction device and deep hole technology, applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of unsafe factors, pollution of the environment, time-consuming and laborious cleaning effect, etc., and achieve convenient and rapid cleaning, low cost, and cleaning Effect Guaranteed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

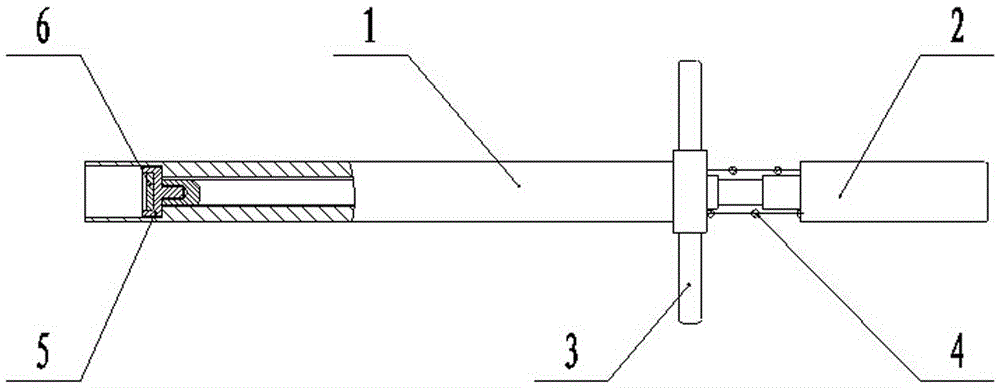

[0009] The magnetic suction device for iron filings in fine and deep holes includes a stepped sleeve 1 with a diameter at the left end larger than that at the right, and a stepped pressure rod 2 with a diameter at the right end greater than that at the left is worn inside the stepped sleeve 1, and the stepped sleeve 1 The right end of 1 is fixed with a handle bar 3 perpendicular to it, and between the right end surface of the stepped sleeve 1 and the stepped surface of the stepped pressure rod 2, a return spring 4 is set on the stepped pressure rod 2, and the stepped pressure rod 2 The left end is threaded with a stepped magnetic isolation fixing sleeve 5 , the stepped surface of the magnetic isolation fixing sleeve 5 is flush with the stepped surface of the stepped sleeve 1 , and a permanent magnet 6 is buckled inside the magnetic isolation fixing sleeve 5 .

[0010] In the specific implementation process, according to the diameter change of the actual processing hole, the dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com