Cylindrical cutter for cutting stainless steel pipes

A technology of cylindrical cutters and stainless steel pipes, which is applied to pipes, turning equipment, branch pipelines, etc., can solve problems such as complex cutting principles, failure of opening work, and difficult cutting, so as to eliminate hidden dangers of vibration and avoid knife jamming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

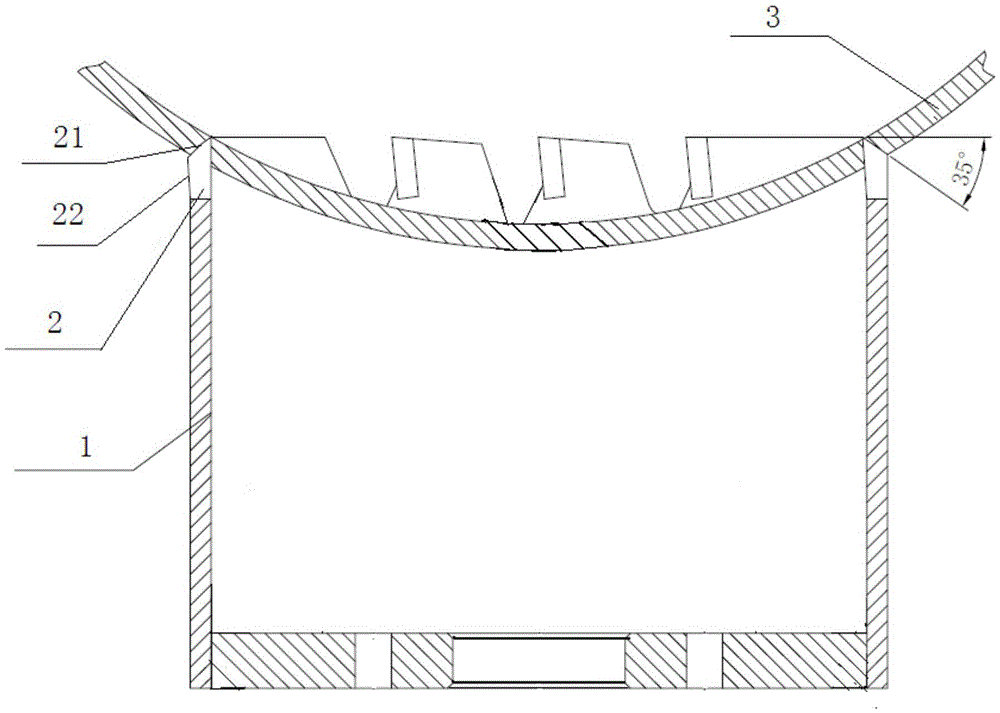

[0012] Such as figure 1 As shown, a cylindrical cutter for cutting stainless steel tubes includes a hollow cylindrical cutter body 1, the cylindrical cutter body 1 is in a toothed structure, and the toothed structure of the cylindrical cutter body 1 is provided with a cutter head 2, The cutting edge of the cutter head 2 includes a main front edge 21 and a beveled edge 22. The slope of the main front edge 21 is 35 degrees, and the slope of the bevel edge 22 is 45 degrees. The cutter head 2 is made of tungsten-cobalt material.

[0013] When in use, the tube body 3 is inserted into the tooth structure of the cylinder cutter body 1, the main front edge 21 first cuts the drill piece and the tube body 3 through the tip of the knife, the inclined edge 22 still has a stable cutting force, and the main front edge After the 21 is cut, the shaking of the opening is el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com