A Planar Redundancy Robot

A redundancy and robot technology, applied in the field of robots, can solve the problems of low positioning accuracy of planar robots, unreasonable layout of drive units, large inertia of robots, etc., to achieve improved stiffness, good stability and accuracy, and reduced rotational inertia. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

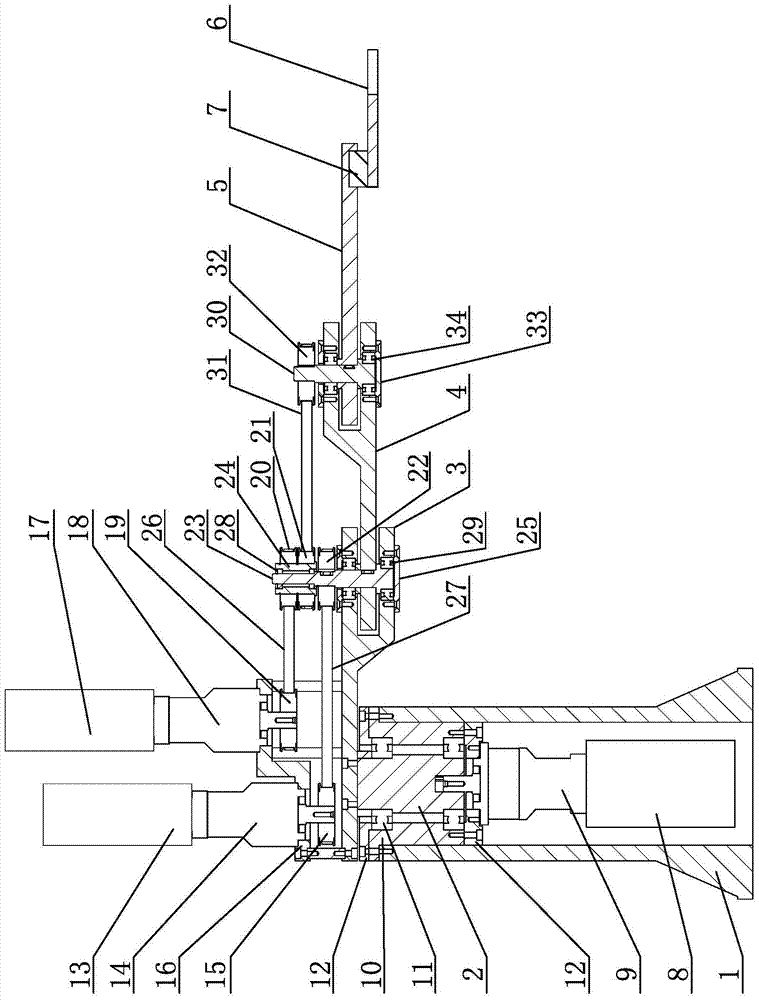

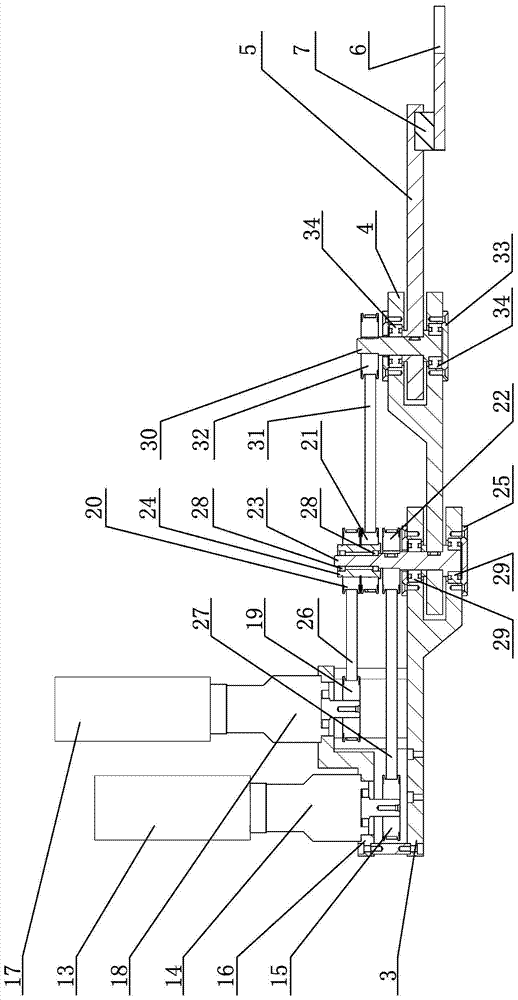

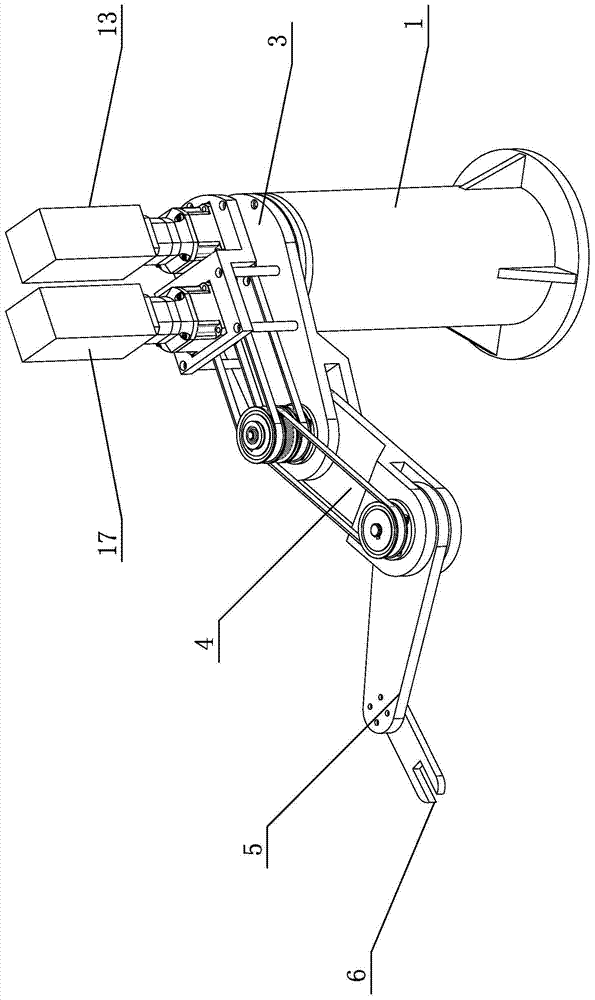

[0013] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, a planar redundant robot described in this embodiment includes a base 1, a first drive unit, a joint shaft 2, a support mechanism, a first connecting rod 3, a second connecting rod 4, and a third connecting rod 5. The operator 6, the second drive unit, the third drive unit, the first relay mechanism, the second relay mechanism, the sensor 7 and the drive unit bracket 16, the first drive unit is installed in the base 1, and the joint shaft 2 The support mechanism is installed in the base 1, the first drive unit is connected to the lower end of the joint shaft 2, the upper end of the joint shaft 2 is connected to one end of the first connecting rod 3, and the other end of the first connecting rod 3 passes through The first transfer mechanism is connected with one end of the second connecting rod 4, the other end of the second connecting rod 4 is connected with one end of the third co...

specific Embodiment approach 2

[0015] Specific implementation mode two: combination Figure 1 to Figure 3 Describe this embodiment, the first drive unit of a kind of planar redundancy robot described in this embodiment includes a first drive motor 8 and a first reducer 9, the rotation shaft of the first drive motor 8 passes through the first reducer 9 and The lower end of joint axis 2 is connected. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0016] Specific implementation mode three: combination Figure 1 to Figure 3 Describe this embodiment, the support mechanism of a planar redundant robot described in this embodiment includes a sleeve 10, two first deep groove ball bearings 11 and two cover plates 12, the sleeve 10 is set on the joint shaft 2 , the upper end of the sleeve 10 is fixedly connected with the upper end of the base 1 through a cover plate 12, the lower end of the sleeve 10 is connected with the first reducer 9 through a cover plate 12, and the upper end and the lower end of the sleeve 10 are respectively provided with a The first deep groove ball bearing 11 and the two first deep groove ball bearings 11 are both sleeved on the joint shaft 2 . Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com