500MPa anti-seismic coiled thread steel and processing method thereof

A processing method and technology of anti-seismic discs, which are applied in the field of hot rolling of steel wire rods for construction, can solve problems such as production and use risks of high-strength anti-seismic discs and snails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

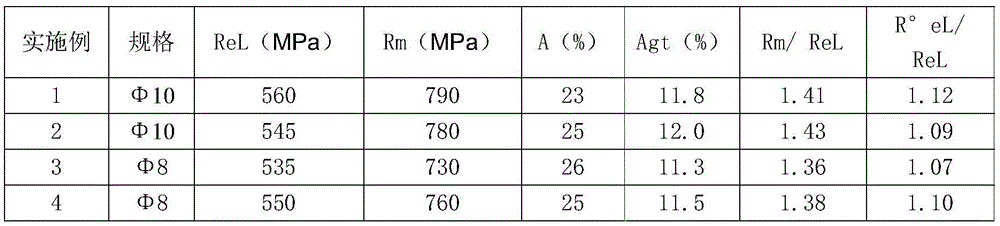

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

[0020] The technical scheme is: (1) the chemical composition (% by weight) of the steel bar is: C0.19-0.25%, Si0.45-0.70%, Mn1.2-1.50%, S≤0.04%, P≤0.04%, V0.08-0.12%. Among them, the amount of V added is added according to the lower limit for specifications of Φ8mm, and the upper limit is added for specifications above Φ10mm. (2) Process route: hot metal pretreatment→converter smelting→electromagnetic stirring (weak stirring)→140mm×140mm billet continuous casting→high-speed wire rod controlled rolling and controlled cooling process. Among them, the final rolling speed is 88.54 m / s for the specification of Φ8mm, and 56.67 m / s for the specification of Φ10mm. (3) The high-line heating, controlled rolling and controlled cooling process is as follows: the billet heating time is 65-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com