Correcting method for residual deformation of magnesium alloy thin flat plate casting

A technology of residual deformation and magnesium alloy, which is applied in the field of magnesium alloy plate casting and forming, can solve the problems of affecting the appearance of the product, residual deformation, and changing the design size, etc., so as to improve stability and reliability, eliminate residual stress, and eliminate residual deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with accompanying drawing:

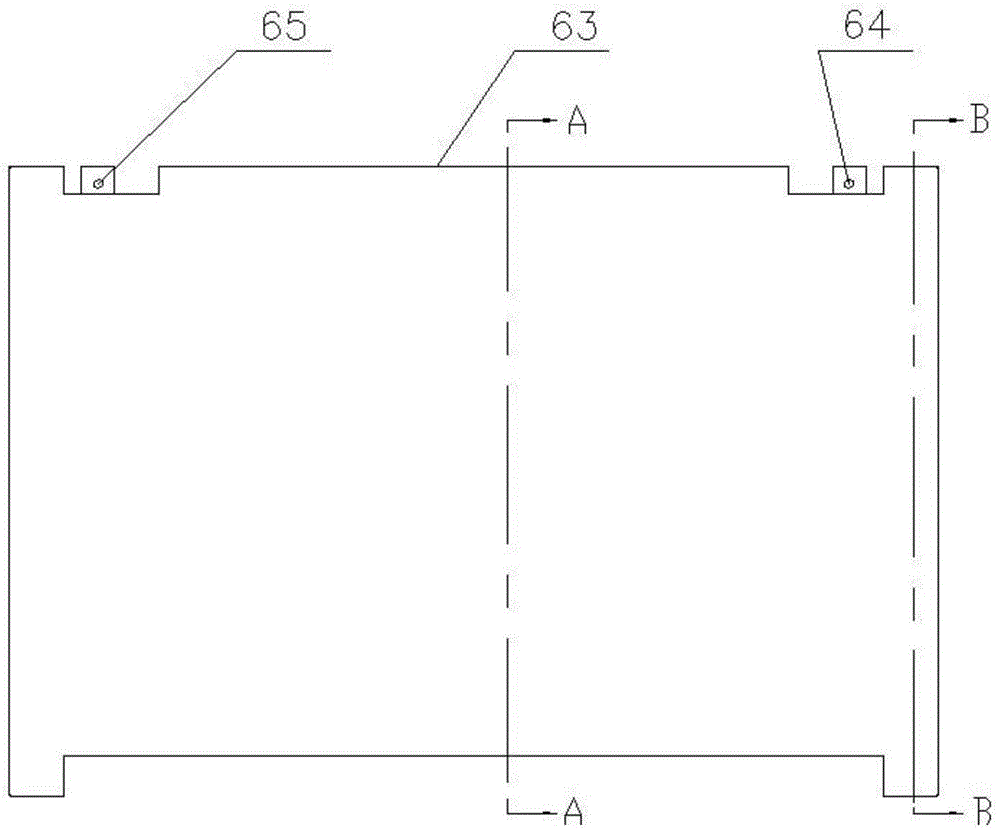

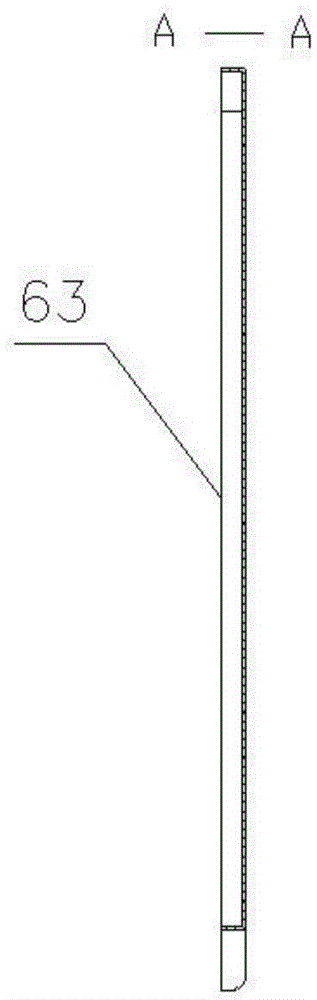

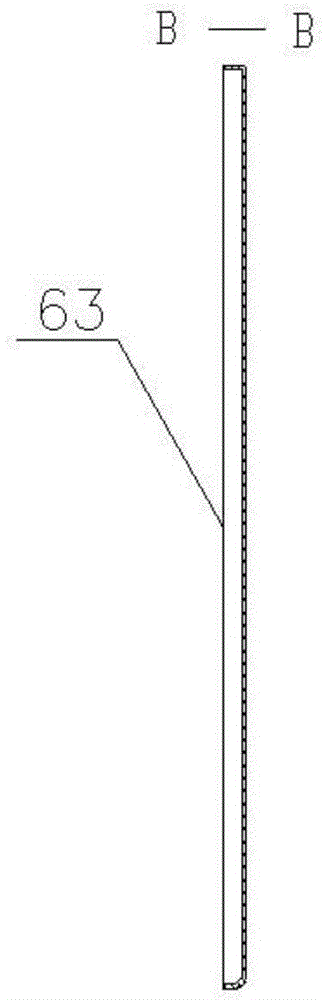

[0048] figure 1 , 2 Shown in , 3 is the structural diagram of the magnesium alloy thin flat casting. The magnesium alloy thin flat casting 63 has a plane size length≦300mm, a width≦200mm, and a flat part thickness≦3mm. The upper part is provided with a first positioning hole 64 and a second positioning hole 65.

[0049] Figure 4 , 5 , shown in 6, is the correction fixture structure diagram, and correction fixture 1 is made up of lower fixture and upper fixture;

[0050] The main structure of the lower fixture includes: lower base plate, lower reference plate, lower plane adjustment block, positioning pin, guide post support, thrust spring, guide post;

[0051] The lower base plate 2 of the lower fixture is a reference frame, and the first lower reference plate 3, the second lower reference plate 4, the third lower reference plate 5, the fourth lower reference plate 6, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com