Positioning device and construction method of capping beam of prefabricated bridge

A technology of prefabricated assembly and positioning device, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of large social influence, large amount of labor, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0128] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

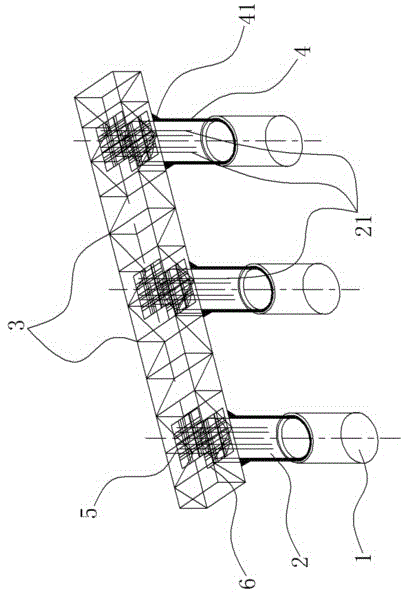

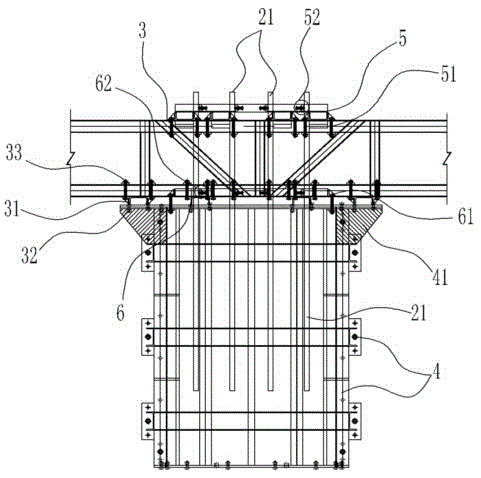

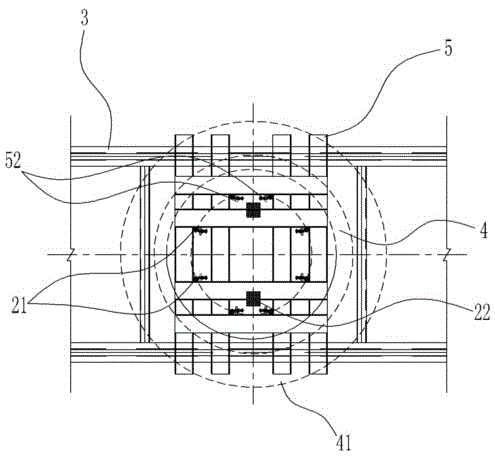

[0129] Such as Figure 1~Figure 8 As shown, 1. Pile foundation, 2. Upright column, 21. Anchor steel bar, 22. Rubber pad, 23. Anchor bolt, 24. Gasket, 3. Truss, 31. Supporting channel steel, 32. Channel steel bolt, 33 .Truss bolts, 4. Column formwork, 41. Column corbels, 5. Upper positioning grid, 51. Upper fixing bolts, 52. Upper positioning bolts, 6. Lower positioning grid, 61. Lower fixing bolts, 62. Lower Positioning bolts, 7. Cover beam, 71. Cover beam grouting channel, 72. Anchor mortar, 73. Paving stone concrete, 8. Grouting formwork, 81. Formwork bolt, 82. Hoop, 83. Hoop bolt, 84 . Sealing rubber strip, 85. Pressure grout nozzle.

[0130] Prefabricated assembly bridge cover beam positioning device and prefabricated assembly bridge cover beam construction method, such as figure 1 , figure 2 As shown, it relates to a construction field of pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com