High-pressure metal powder supply system based on pressure difference control

A metal powder and supply system technology, which is applied to the system field of supplying metal fuel powder to a metal engine, can solve the problems of reduced engine working efficiency, inability to work stably and continuously, and reduced metal powder concentration, and achieves the effect of improving working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

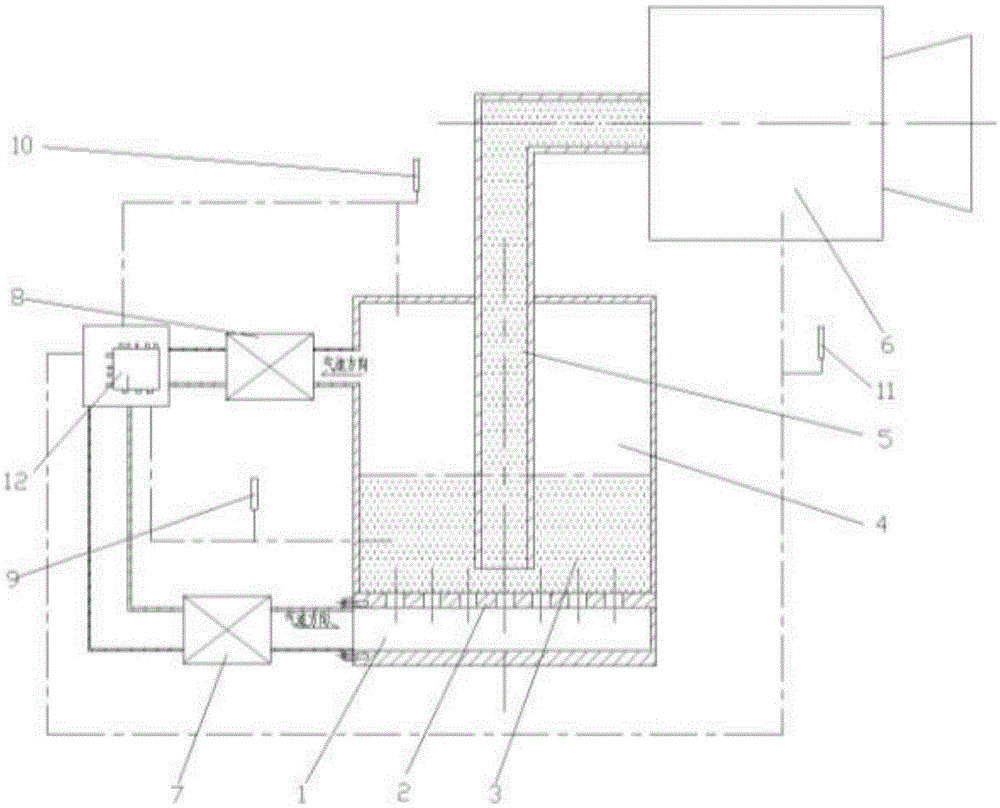

[0012] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0013] combine figure 1 , a metal powder high-pressure supply system based on differential pressure control in the present invention, an air inlet channel 1 is opened at the lower part of the medicine box, and an orifice plate 2 is arranged between it and the inside of the medicine box, and a metal powder 3 is installed above the orifice plate 2, Above the metal powder is air 4, and the metal powder is supplied into the combustion chamber 6 through the combustion chamber supply pipe 5, and an exhaust pipe is arranged on the top of the medicine box.

[0014] The air intake pipeline is provided with an air intake regulating valve 7, which is connected with the medicine box by a pipeline, and the exhaust pipeline is provided with an exhaust regulating valve 8, which is connected with the medicine box by a medicine box, respectively used to control the intake speed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com