Sleeve type heat regenerator device

A regenerator and casing type technology is applied in the field of casing type regenerators, which can solve the problems of heavy workload and complex structure, and achieve the effects of less consumables, safe and reliable operation, and avoiding excessive friction loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

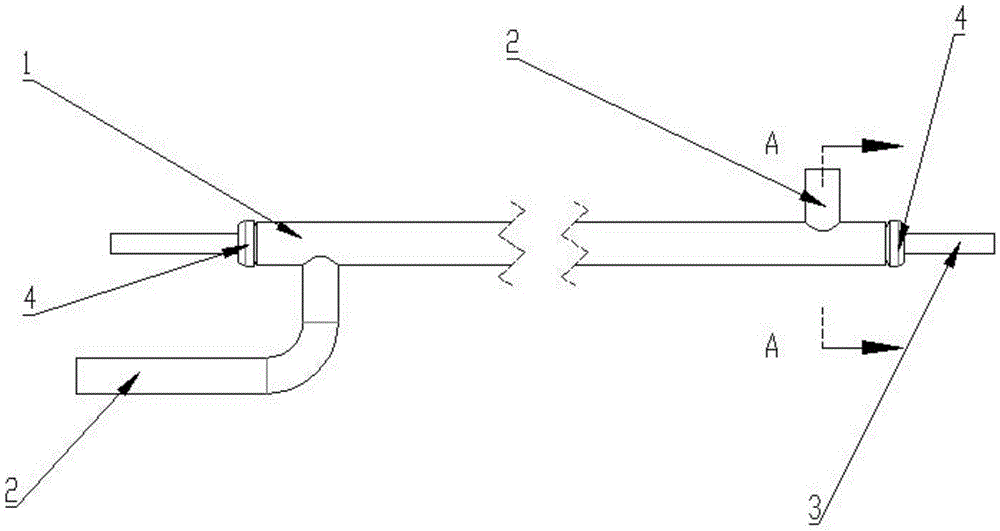

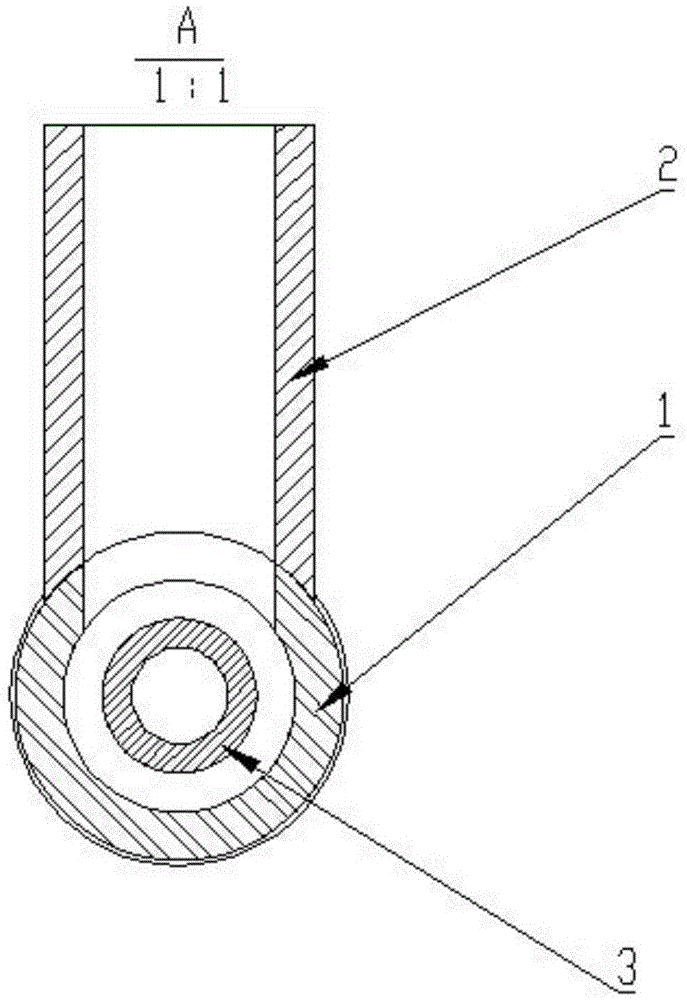

[0012] Referring to the accompanying drawings, a casing type regenerator device includes a first stainless steel tube 1, and a tube cap 4 with a through hole is provided at both ends of the first stainless steel tube 1, and the through hole of the tube cap 4 is connected to There is a third stainless steel pipe 3, and the third stainless steel pipe 3 passes through the first stainless steel pipe 1, and the second stainless steel pipe 2 is arranged on the outer wall of the first stainless steel pipe 1. The shell-and-tube heat exchanger is a heating type shell-and-tube heat exchanger. The diameter of the first stainless steel tube 1 is larger than that of the second stainless steel tube 2 . The diameter of the second stainless steel pipe 2 is larger than that of the third stainless steel pipe 3 . The outer walls of the first stainless steel pipe 1 , the second stainless steel pipe 2 and the third stainless steel pipe 3 are provided with insulation layers.

[0013] The third sta...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap