Integrated flat single-face phase-change restraining heat conducting board type heat exchanger and manufacturing method thereof

A phase change suppression, heat exchanger technology, applied in the direction of heat exchange equipment, heat exchanger type, indirect heat exchanger, etc., can solve the problem that the heat exchange area of the evaporator cannot be fully utilized, the refrigerant channel cannot be covered, and the temperature of the plate surface is not high. Uniformity and other issues to achieve the effect of improving heat dissipation capacity and heat exchange efficiency, increasing temperature difference and effective heat transfer area, and fast heat transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

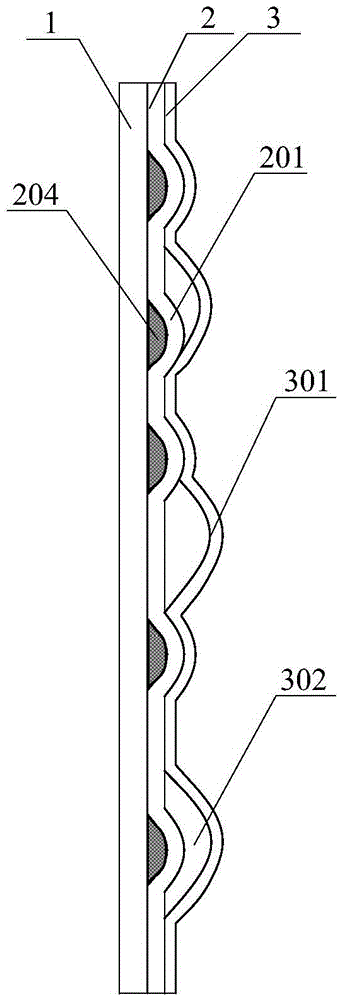

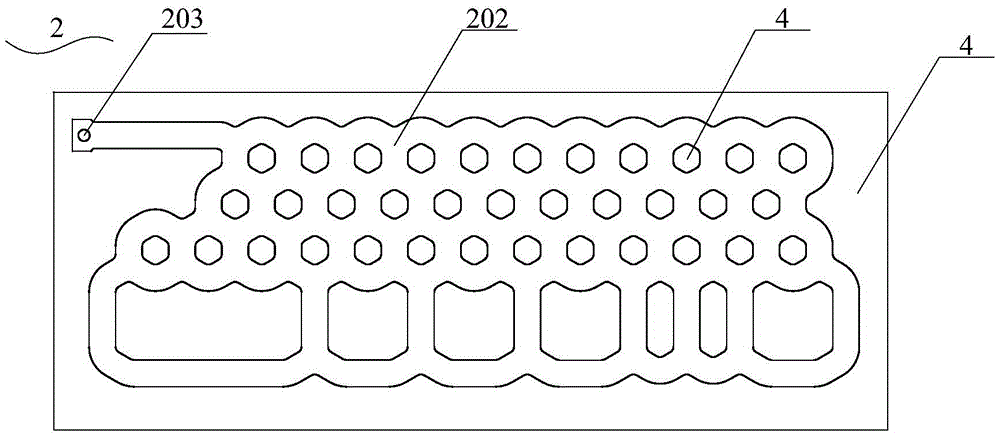

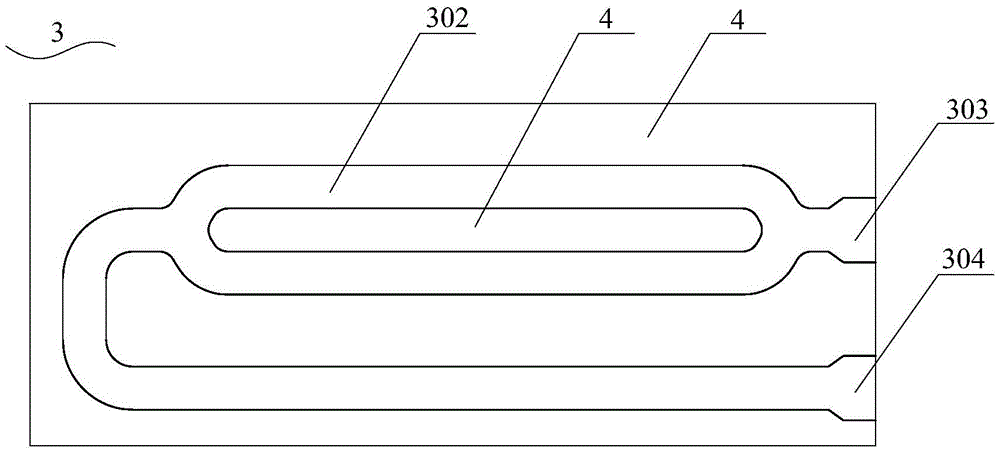

[0052] see Figure 1 to Figure 3 , the present invention provides an integrated single-sided flat phase change suppressed heat transfer plate heat exchanger, the integrated single-sided flat phase change suppressed heat transfer plate heat exchanger includes a heat exchange plate with a composite plate structure; the heat exchange One surface of the plate is a plane; a refrigerant channel 302 with a specific structural shape and a thermal superconducting circuit 202 with a specific structural shape are formed in the heat exchange plate; the thermal superconducting circuit 202 is a closed circuit, and the heat The superconducting circuit 202 is filled with a heat transfer medium 204 . The thermal superconducting circuit 202 is filled with a heat transfer medium 204 to form a phase change suppression heat transfer device, which improves the heat transfer rate and temperature uniformity of the heat exchange plate.

[0053] As an example, the heat transfer working medium 204 is a...

Embodiment 2

[0066] see Figure 4 , the present invention also provides a method for manufacturing an integrated single-sided flat phase transition suppressed heat transfer plate heat exchanger, the manufacturing method of the integrated single-sided flat phase transition suppressed heat transfer plate heat exchanger includes:

[0067] S1: Provide the first board, the second board and the third board in total three boards, roughen and blow off one side of the first board and the third board, and roughen both sides of the second board and blown clean; the first plate, the second plate and the third plate are preferably sheared and shaped by a shearing process and have the same thickness or different thicknesses;

[0068] S2: Using the graphite printing method to form interconnected graphite lines with a specific shape on the roughened surface of the first plate and the roughened surface of the third plate, located on the roughened surface of the first plate and the roughened surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com