Electric charge power heat pipe

A power heat pipe and electric charge technology, which is applied in the field of heat pipes, can solve problems such as the inability of components to dissipate heat and the obstruction of liquid return, and achieve the effect of effective heat dissipation circulation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

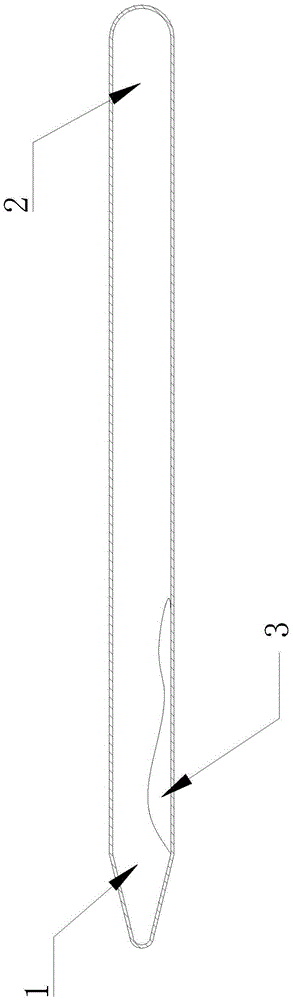

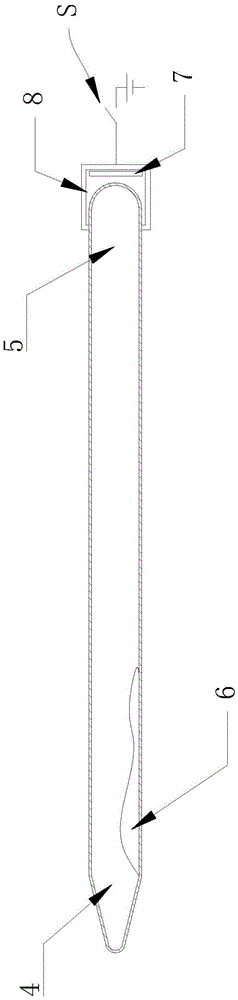

[0019] Such as figure 2 As shown, the electric charge dynamic heat pipe of the present invention has a vacuum tube body, and the vacuum tube body has a cooling section 4 and a heating section 5, and the radius of the cooling section 4 tapers into a conical shape. A certain amount of negative ion water 6 is also filled in the vacuum tube body, and the negative ion water evaporates when heated in the heating section 5, and flows back to the cooling section 4, then cools and recondenses into a liquid, and then flows back to the heating section 5, so that the heat dissipation function is realized by circulation.

[0020] A ceramic sleeve 8 is arranged at the end of the heating section 5 for insulation, and an anode plate 7 is arranged between the ceramic sleeve 8 and the end of the heating section 5 to drain the negative ion water 6 . In addition, an auxiliary circuit is provided. The positive electrode of the power supply is connected to the anode plate 7 through the switch S. W...

Embodiment approach 2

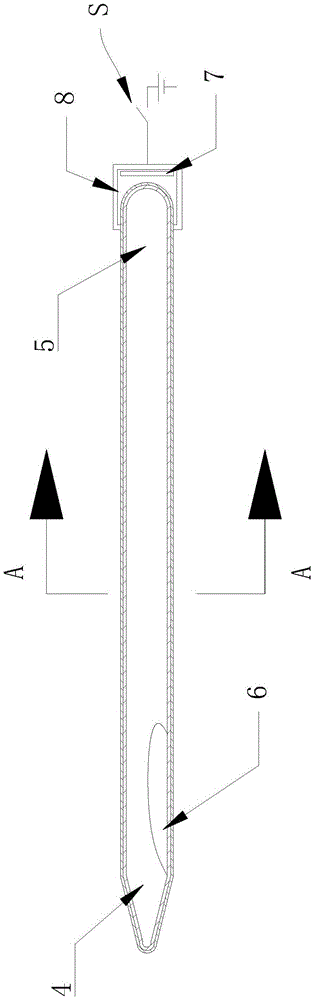

[0023] The structure of the charge dynamic heat pipe of the present embodiment is as follows: Figure 3-4 shown. The vacuum tube body has a cooling section 4 and a heating section 5. The tube body is filled with negative ion water 6. The end of the heating section 5 is provided with a ceramic sleeve 8 and an anode plate 7. It also has an auxiliary circuit connected to the anode plate 7. The above structure is the same as that of Embodiment 1, and will not be repeated here. Such as Figure 4 As shown in the cross-sectional view of the tube body, a capillary return layer 10 is provided on the lumen wall 9 of the tube body. The capillary reflow structure 10 can be sintered copper powder and other prior art to form a capillary structure, such as braided mesh layer, sintered copper powder layer or sintered fiber layer.

[0024] For the working principle of this embodiment. The negative ion water 6 is absorbed by the anode plate 7 and evaporates into water vapor in the heating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com