Compensation method for measured thickness of zinc aluminized layer

A technology of measuring thickness and compensation method, which is applied in the direction of measuring devices, instruments, and using wave/particle radiation, etc., can solve the problems of no thickness compensation function of galvanized layer and measurement value error, so as to improve thickness control accuracy and reduce measurement Effect of Thickness Deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific process and steps of the method for measuring the thickness compensation of the galvanized layer of the present invention are:

[0027] 1. Determine the compensation coefficient

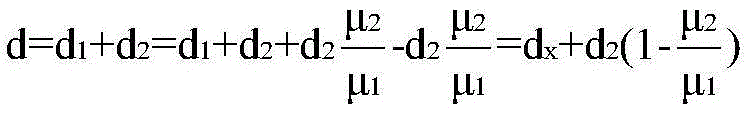

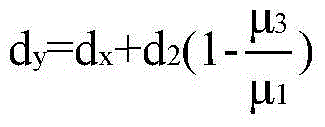

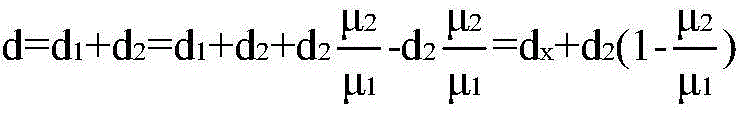

[0028] According to the measurement principle of the strip steel thickness gauge, when the rays emitted by the ray source pass through the measured object, attenuation will occur, and the attenuation range depends on the material and thickness of the measured object. When the material of the measured object remains unchanged, then The intensity of rays passing through the measured body will decay exponentially with the thickness of the measured body. When the thickness gauge measures the total thickness of the galvanized sheet, the intensity of the ray after passing through the galvanized sheet is I=I 0 e -(μ1d1+μ2d2) ,

[0029] resulting in the measured thickness

[0030] I 0 : initial intensity of the ray; d x : Thickness measured by the thickness gauge; d 1 : substrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com