Low-friction micro optical cable suitable for air blowing and conduit wiring

A low-friction, air-delivered technology, used in light guides, optics, optical components, etc., can solve the problems of high mechanical strength requirements of optical cables, high initial investment, low construction efficiency, etc., to improve the quality of operation and maintenance, reduce initial construction costs, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

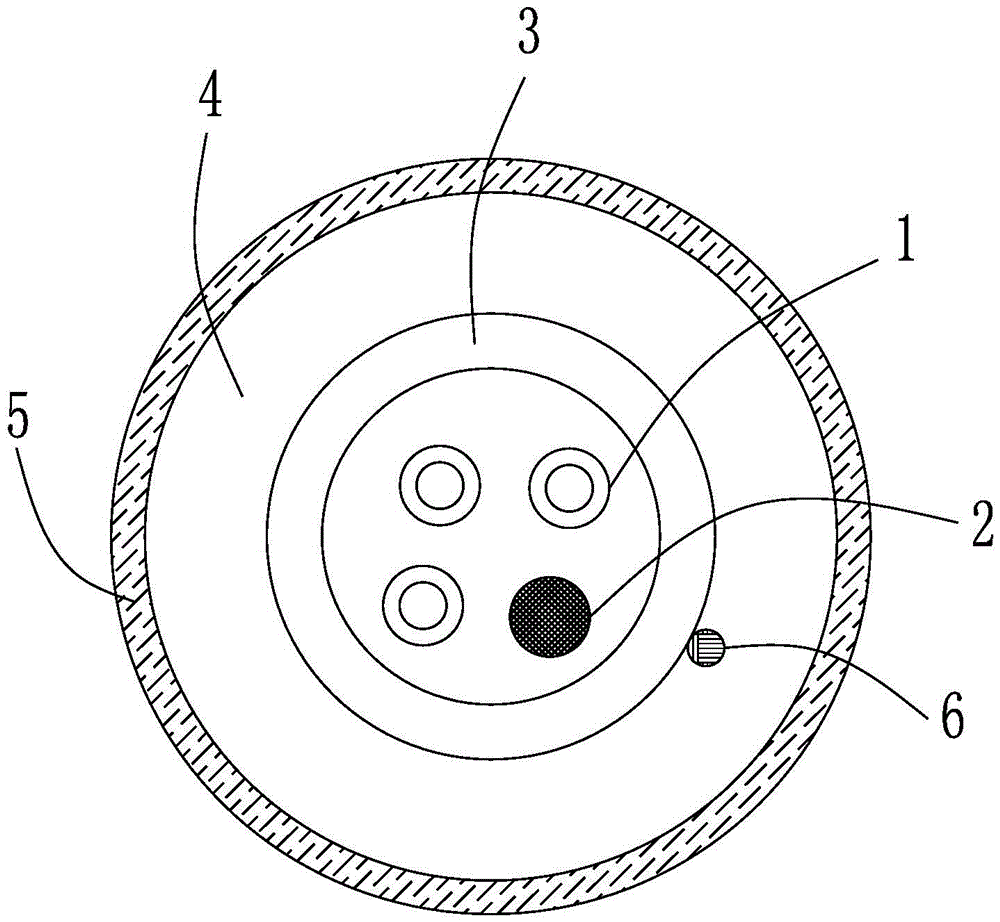

[0023] see figure 1 As shown, the embodiment of the present invention provides a low-friction micro-optical cable suitable for air delivery and pipe routing, including a cable core, an inner sheath 3 and a sheath 4 from the inside to the outside in sequence, and the material of the inner sheath 3 is acrylic One of resin, nylon, polycarbonate and PBT materials, the inner sheath 3 is coated on the outside of the cable core, and if the inner sheath covers 2 or 4 optical fibers 1, the outer diameter of the inner sheath 3 is 0.85±0.1mm; if 6 optical fibers 2 are covered, the outer diameter of the inner sheath 3 is 0.9±0.1mm; if 8 optical fibers 2 are covered, the outer diameter of the inner sheath 3 is 1.1±0.1mm; if If 12 optical fibers 2 are covered, the thickness of the inner sheath 3 is 1.2±0.1 mm; if 24 optical fibers 2 are covered, the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com